Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Project for the construction of a boiler house and heating networks

Technical and economic characteristics of the capital construction object

Land area, m2: 261,0

Building area, m2: 100,0

Total building area, m2: 87,04

Construction volume of the building, m3: 297,1

Number of floors, floor: 1

Productivity, MW: 4

Estimated cost at the 2001 base price level (without VAT)

Total: thousand rubles: 14792,75

Construction and installation works, thousand rubles: 7533,38

Equipment, thousand rubles: 4897,30

Other expenses, thousand rubles: 2362,07

including:

PIR, thousand rubles: 1209,71

refundable amounts, thousand rubles: 73,57

Estimated cost at the current price level as of January 2012 (including VAT)

Total: thousand rubles: 65896,27

Construction and installation works, thousand rubles: 36387,24

Equipment, thousand rubles: 17693,82

Other expenses, thousand rubles: 11815,21

including:

PIR, thousand rubles: 5386,33

VAT, thousand rubles: 10010,66

refundable amounts, thousand rubles: 395,23

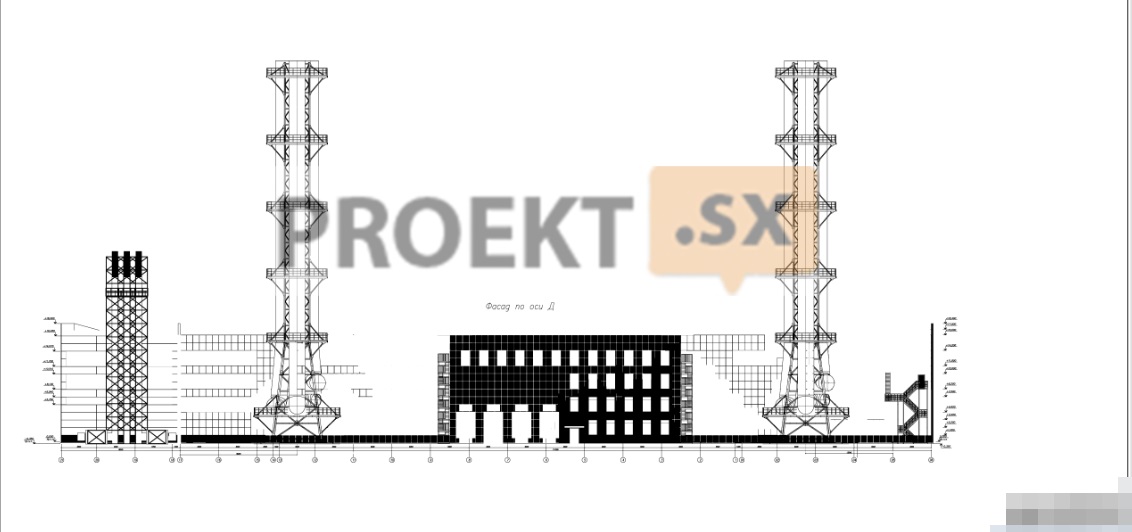

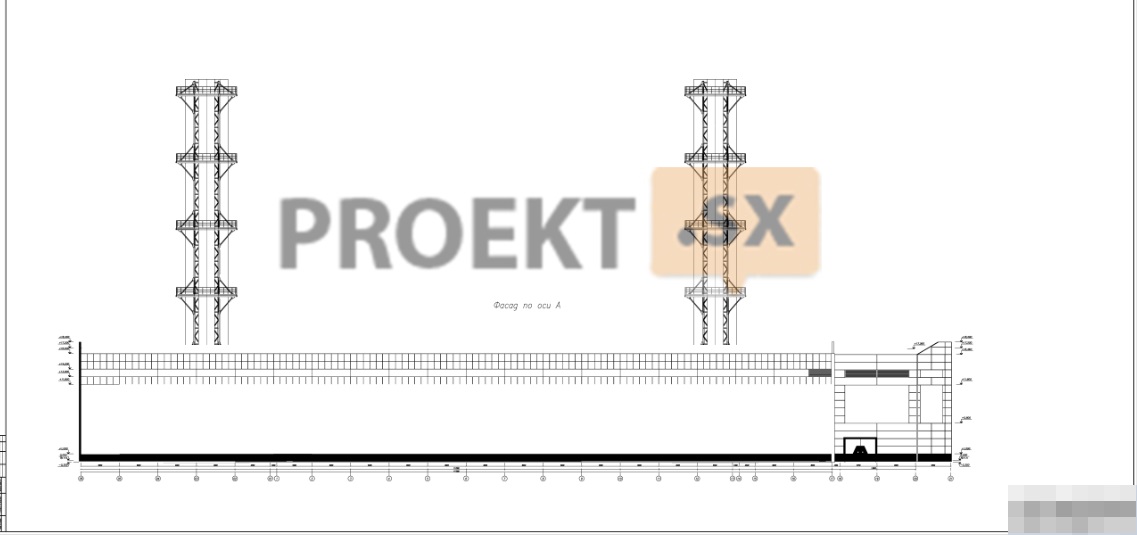

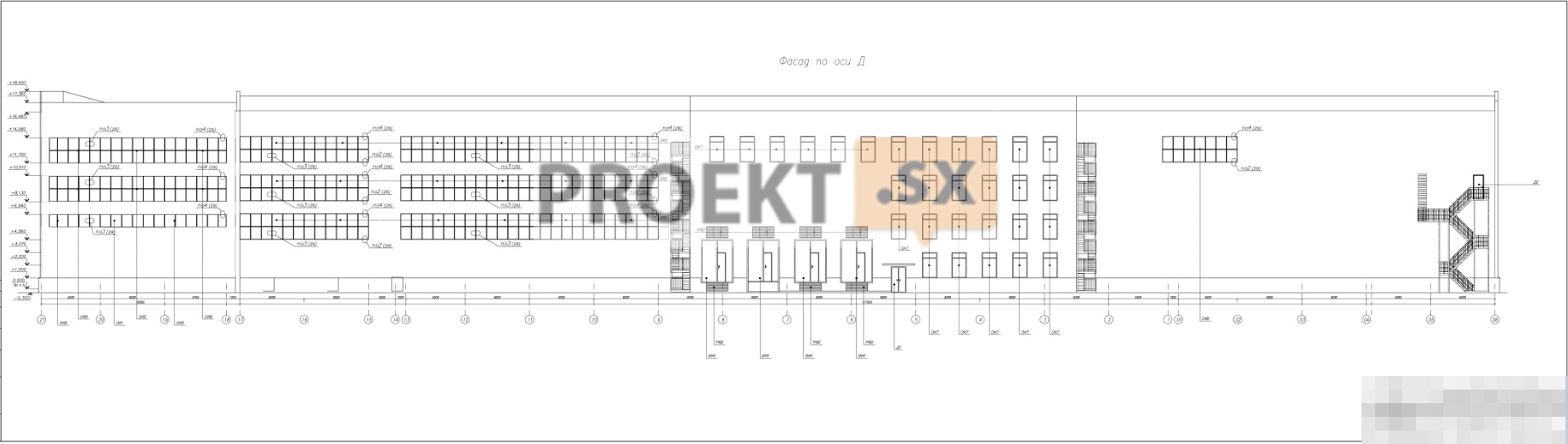

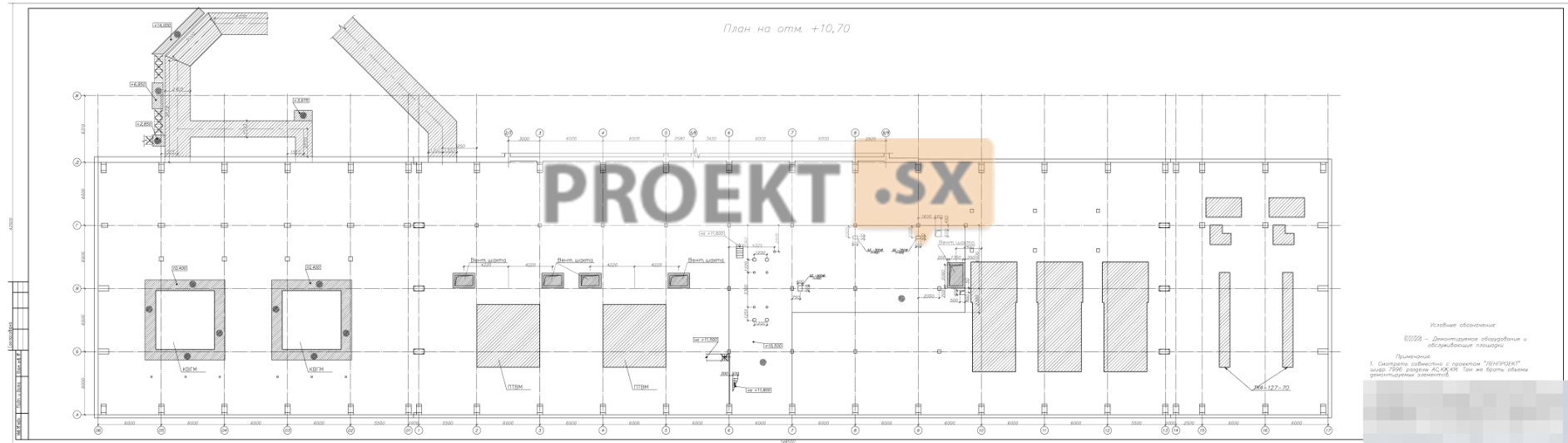

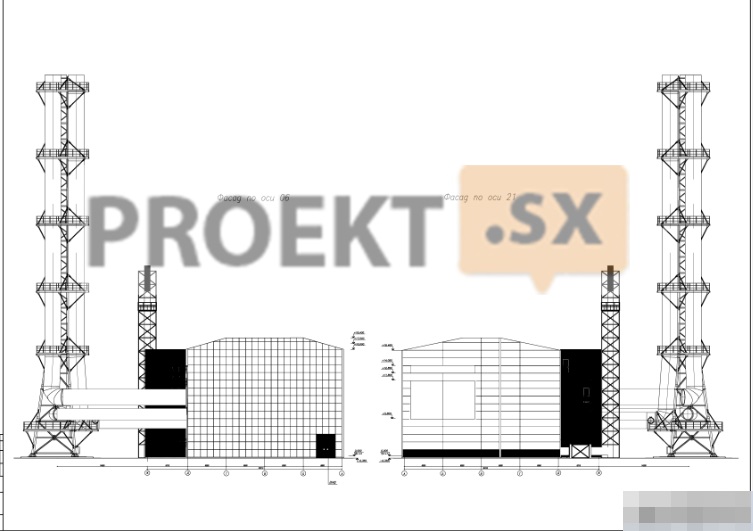

Architectural and space-planning solutions

The design documentation provides for the construction of an automated boiler house with a diesel generator room. The building of the boiler house is one-story, rectangular in plan, with dimensions in the axes of 12,80 x 6,80 m. The height of the building from the planning ground level to the top of the cover is 3,43-3,33 m. For a relative mark of 0,000, the mark of the finished floor of the boiler room was taken. A boiler room with one external entrance and a diesel generator room with a separate external entrance and an entrance to the boiler room were designed in the building. Two outer walls of the building (along axis A and axis 3) are designed from hinged "sandwich" panels with a thickness of 100 mm, and two outer walls of the building (along axis B and along axis 1) are designed (to ensure sound insulation) with a thickness of 120 mm from two hinged "sandwich" panels 60 mm thick. The walls between the boiler room and the diesel generator room are designed from hinged “sandwich” panels 100 mm thick. There are no window blocks in the boiler room and diesel generator room; hinged “sandwich” panels are designed as easily dumped structures in the area where the boilers are located. The work of the boiler room and diesel generator is automated, without a permanent stay of service personnel. The roof is rolled flat with an unorganized external drain. Gas ducts (two chimneys) from the boiler house are designed on a separate foundation. The height from the planning mark of the earth to the top of the pipe is 26.15 m.

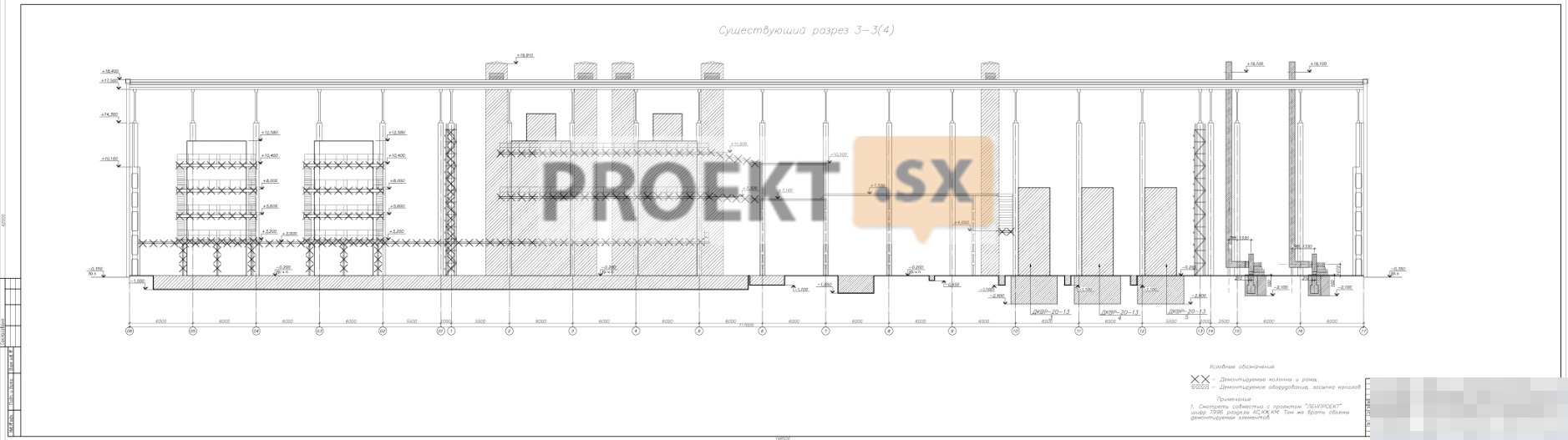

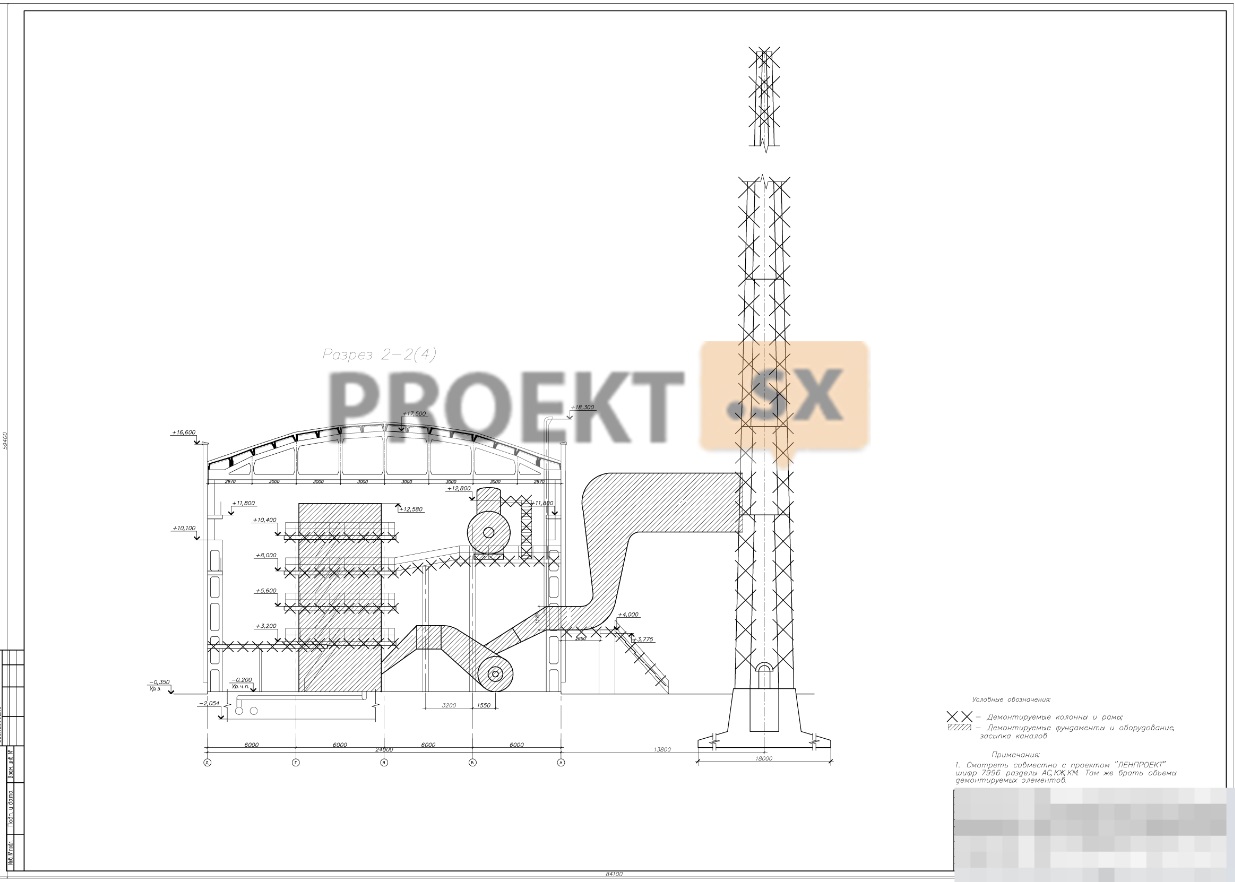

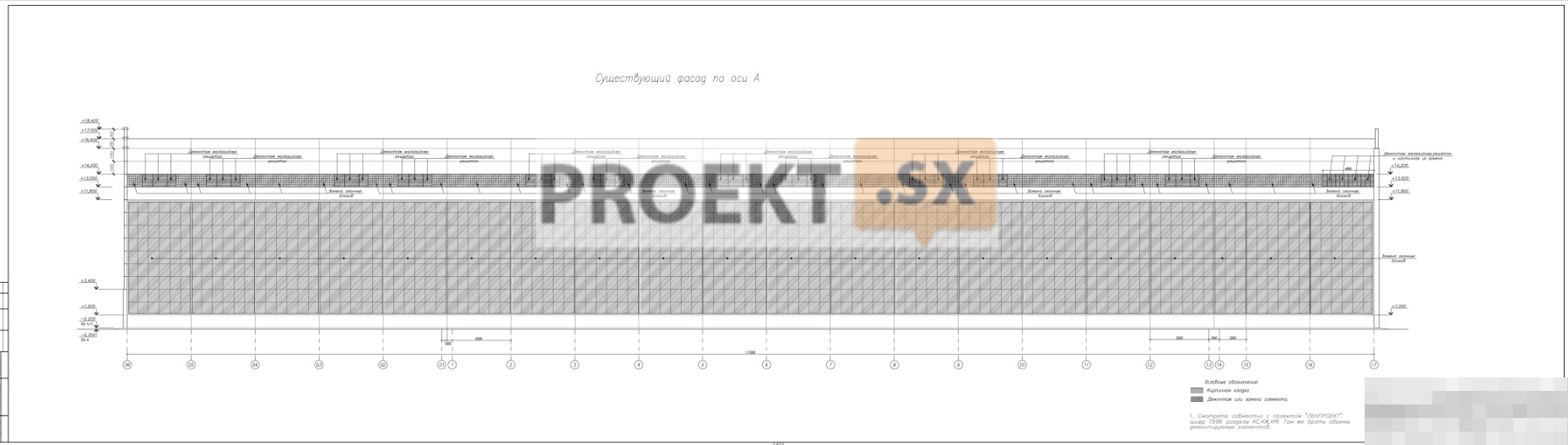

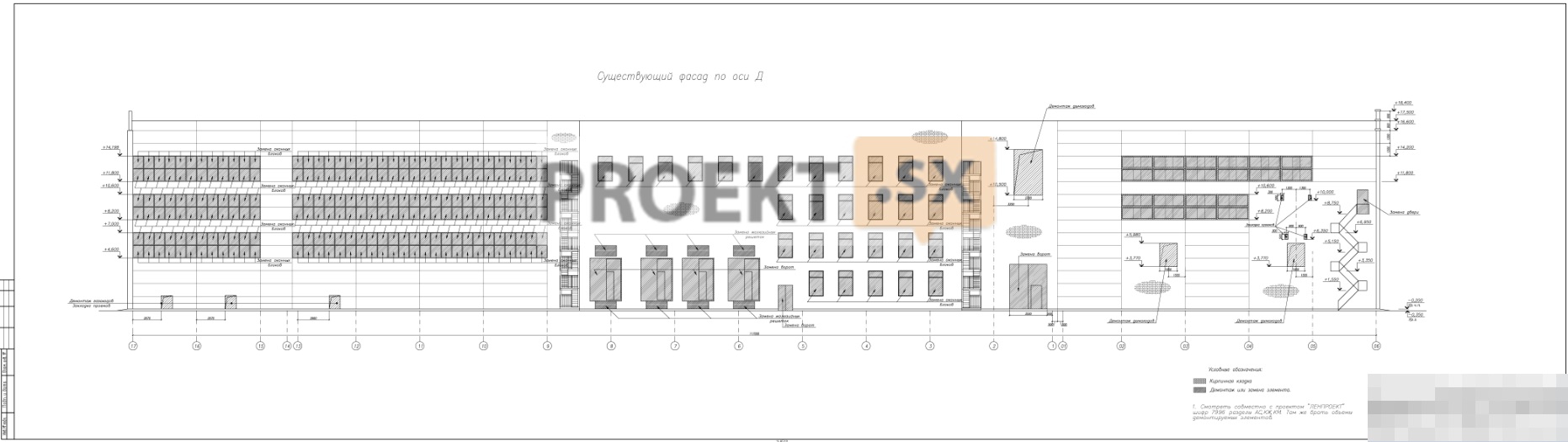

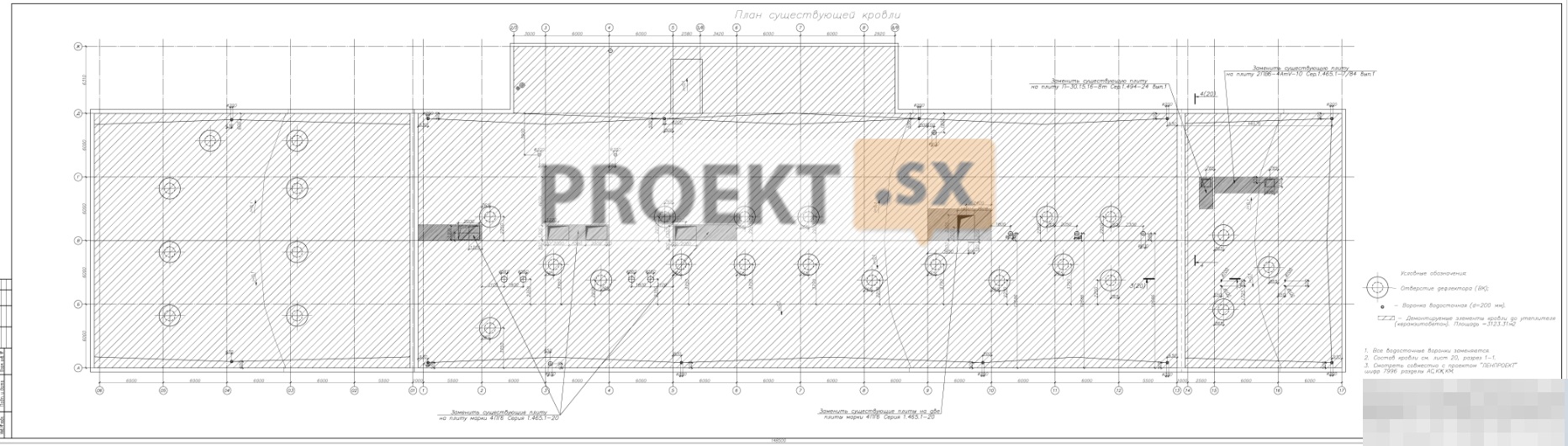

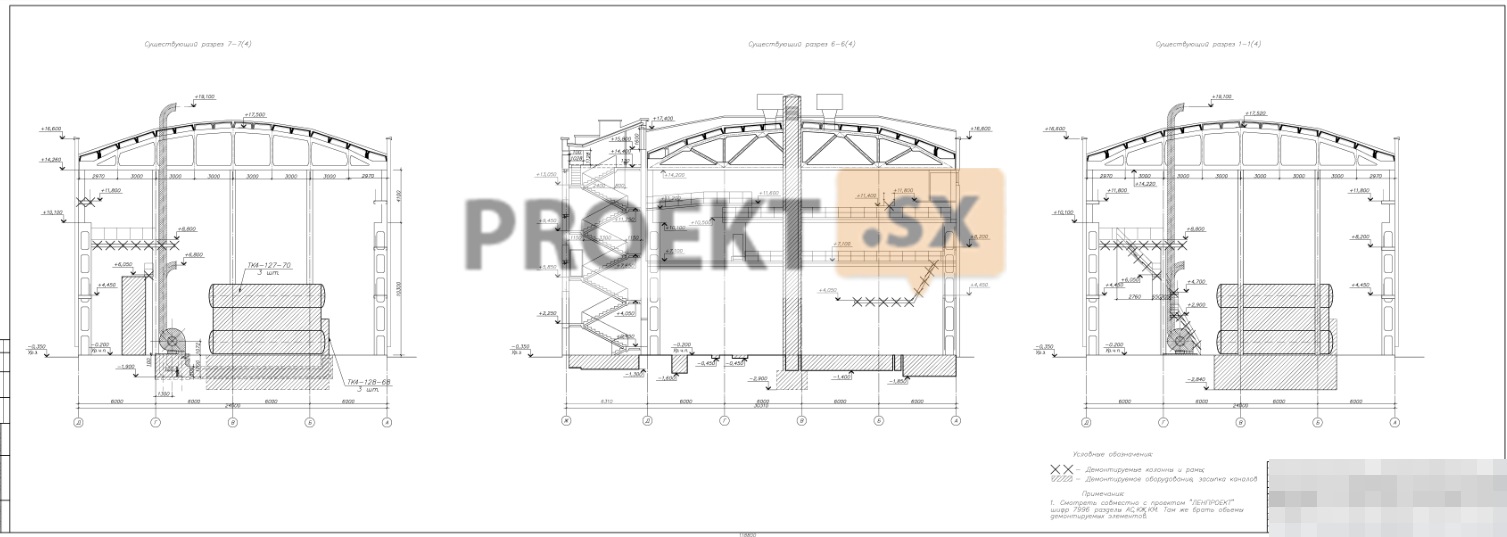

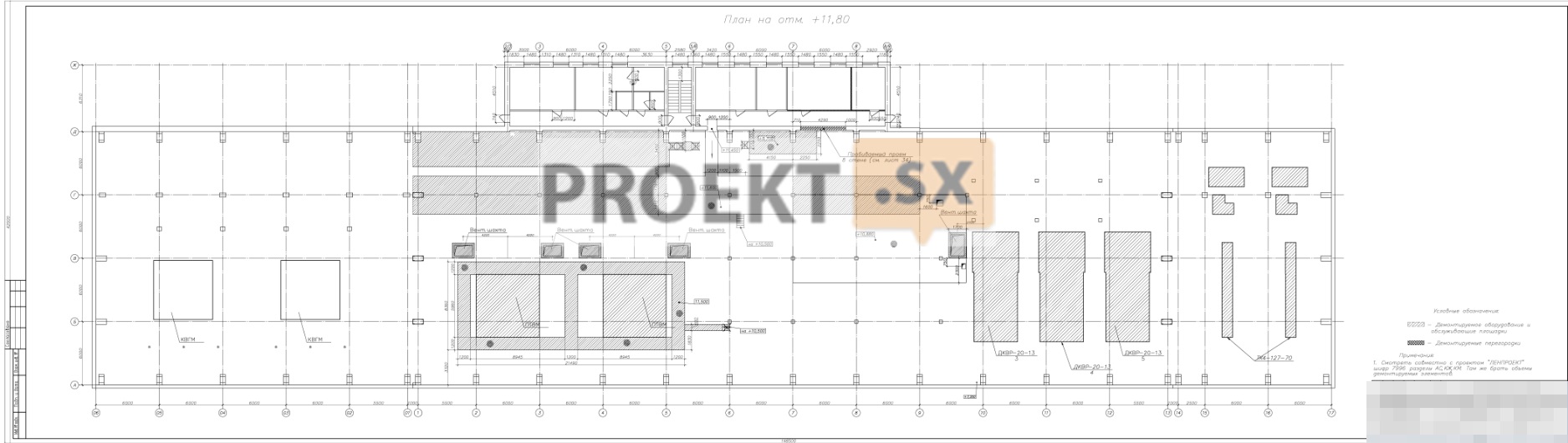

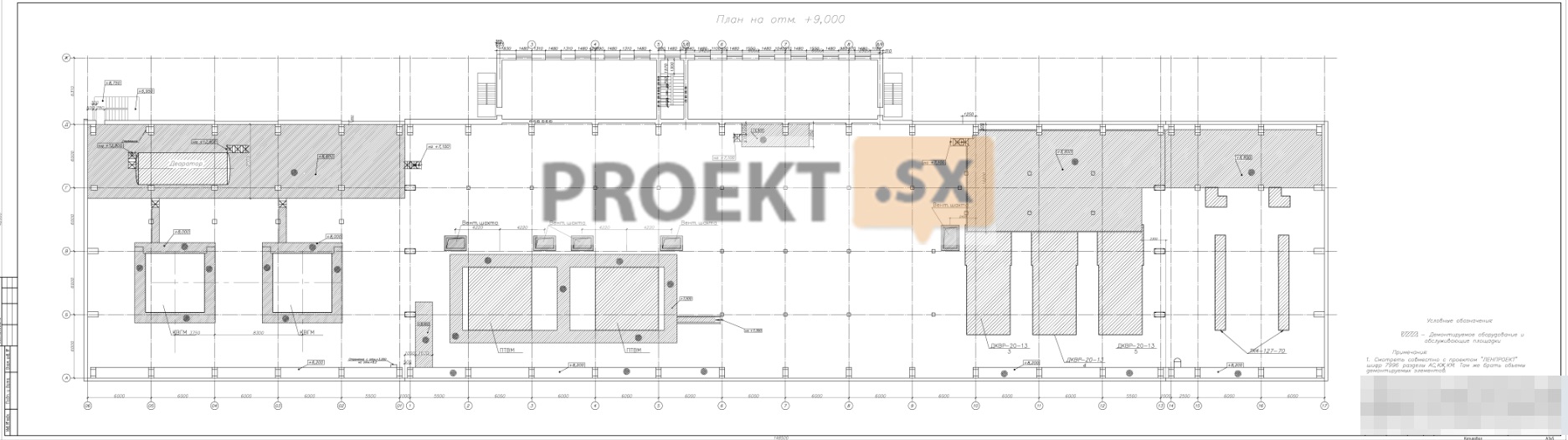

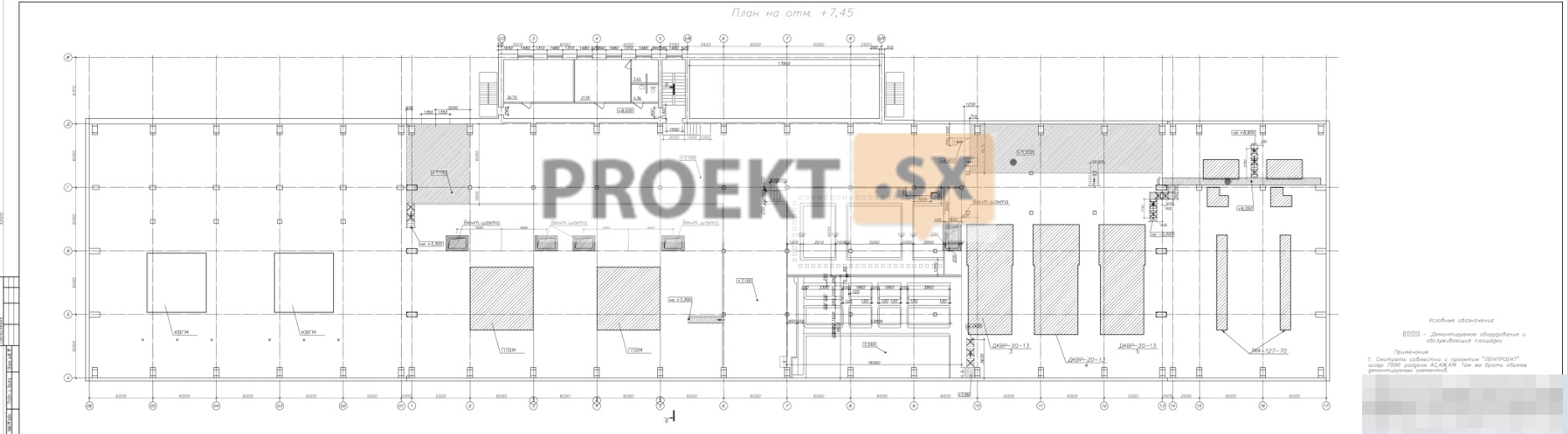

Structural and space-planning solutions

In accordance with technical surveys, the existing building was built in the second half of the XNUMXth century according to a wall structural scheme. The project provides for the dismantling of the above-ground structures of the boiler house in accordance with the targeted program. The foundations of the existing boiler house are made of rubble masonry. Foundation laying depth 1.68÷2.08 m, base width 760÷1140 mm. At the base of the foundations, sands are silty, medium dense with E=130 kg/cm2, φ=28, epeski=0,70, c=0,03 kg/cm2. The technical condition of the foundations is operational. The project provides for the dismantling of the above-ground part of the boiler house and the construction of a modular boiler house. The building was designed according to the frame structural scheme. The boiler room is designed from metal structures with sandwich paneling. Columns - a closed bent profile 100x4 (connections from a bent profile 80x4) in accordance with GOST 30245-2003. Beams - bent-welded pipes 100x4 and 80x4 in accordance with GOST 30245-2003. The cover is designed from profiled sheet H60-845-0,8 along the beams. External walls are hinged "sandwich" panels 100 mm and 120 mm thick (paired "sandwich" panels 60 mm thick). The lower (support) frame is made of bent-welded pipes 150x100x6 according to GOST 30245-2003. Spatial rigidity and stability of buildings is ensured by the joint work of vertical and horizontal connections. The foundations of the boiler house are existing strip foundations, on which a monolithic reinforced concrete slab 300 mm thick, concrete B15, W6, F100, is laid. A 100 mm thick concrete preparation is provided under the slab. Chimneys (2 flues with an outer diameter of 700) with a height of ~26 m are fixed on a spatial metal structure installed on its own foundation. The metal structures of the chimneys are made of racks (a pipe with a diameter of 159x6) united by a lattice of a bent-welded pipe 80x40x5. The foundations for the pipe are columnar from monolithic reinforced concrete. Concrete B15, W6, F100. The relative elevation of 0.00 corresponds to the absolute elevation of +5,38 m. In accordance with the report on engineering and geological surveys, silty sands of medium density with E=130 kg/cm2, φ=28, epesks=0,7, c=0,03 kg/cm2 serve as the basis. The design resistance of the foundation soils is not lower than R=1,63 kg/cm2. The pressure on the ground does not exceed p=0,75 kg/cm2. The maximum level of groundwater at a depth of 0,5 m (absolute elevation 4,6÷5,40 m). Groundwater is slightly aggressive to concrete of normal permeability in terms of the content of aggressive carbon dioxide and the content of sulfates. In order to protect the concrete of underground structures, the concrete grade for water resistance is W6, the concrete surface is protected by coating with a waterproofing compound. The expected average settlement of the building is not expected, since the designed building is lighter than the demolished one. Pipe stability is guaranteed. According to the results of the survey, the category of the technical condition of buildings in the surrounding area is 2nd category.

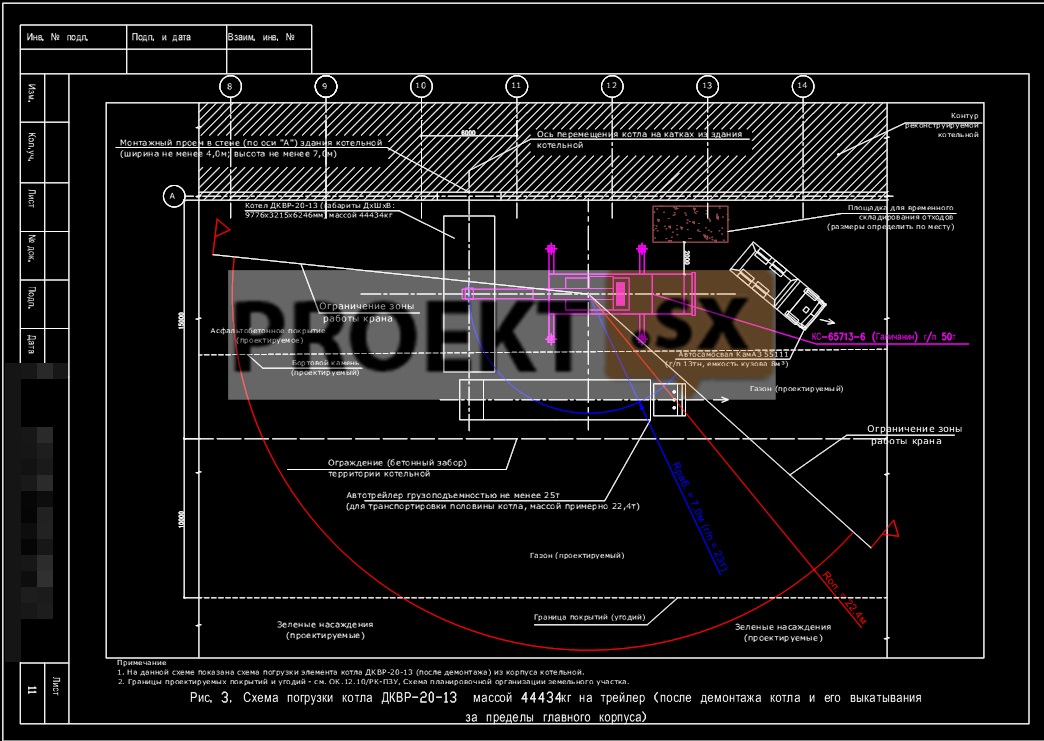

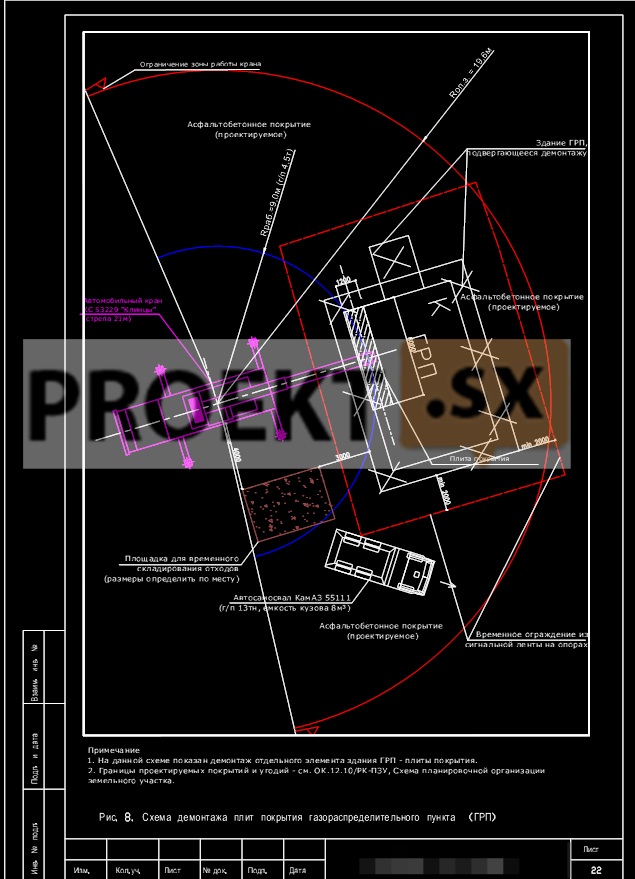

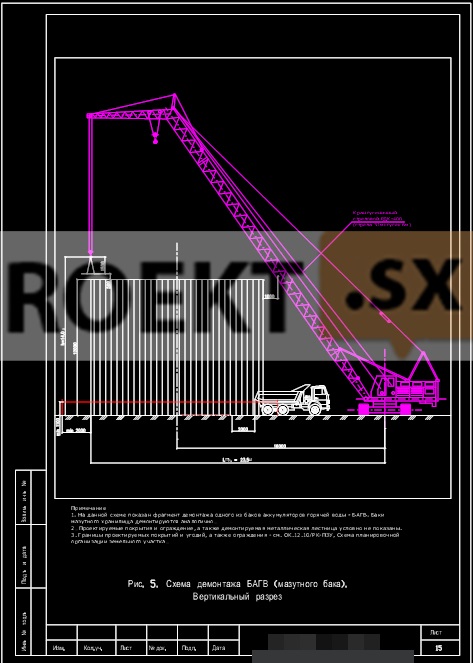

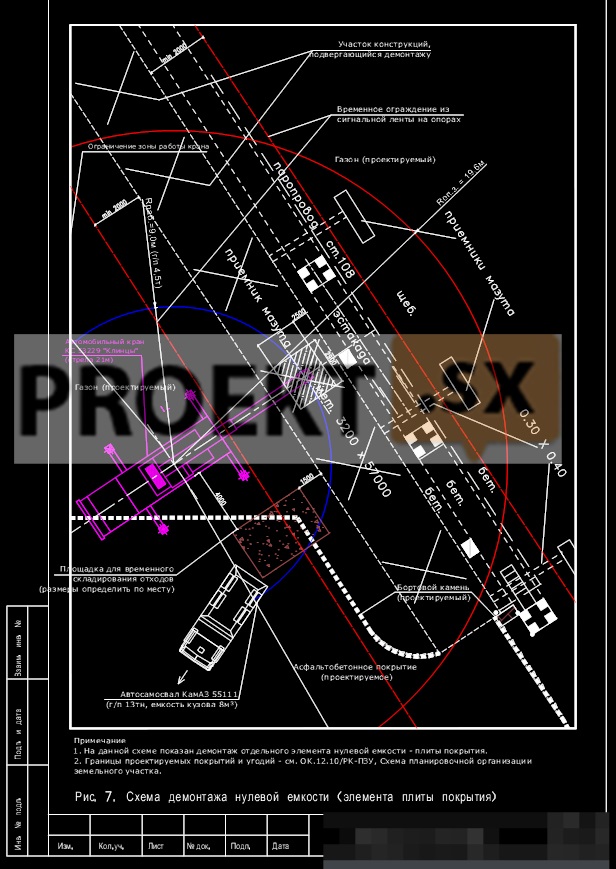

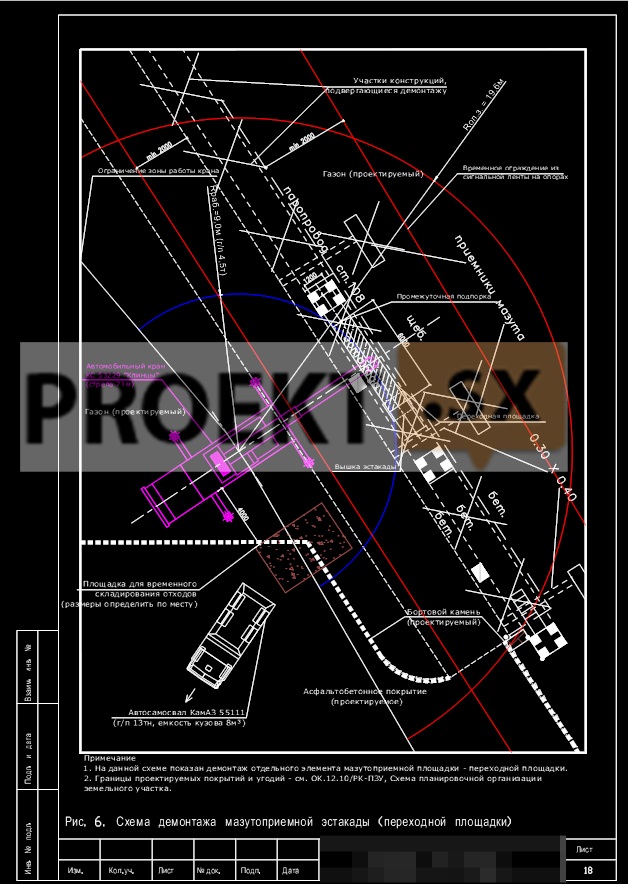

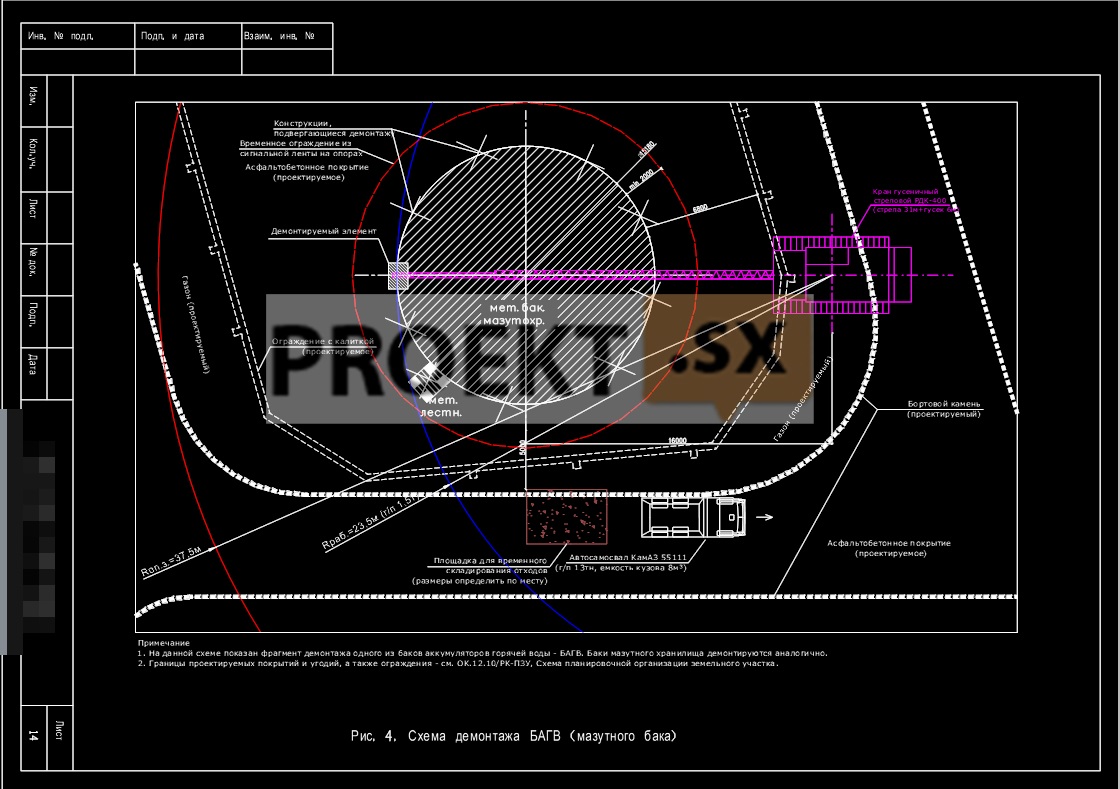

Organization of construction

The construction organization project provides for the construction of a boiler house building, the installation of chimneys, and the arrangement of utilities. During the preparatory period, the existing boiler house is being dismantled. The construction master plan was developed on a scale of 1:500 for the construction period, taking into account the work of the preparatory period. Temporary solid fencing of the construction site is provided in accordance with the requirement of GOST 23407-78. Entry and exit of vehicles and construction equipment to the construction site is provided from the side of the avenue. At the exit from the construction site, it is planned to wash the wheels of vehicles with circulating water supply. The mechanization of construction works is complex, using mechanisms such as: KS-4572, KS-5579.21, EK-12-10. The work is to be carried out in 1 shift. Materials are stored in open areas with a margin of no more than 5 days. Provision of construction materials is provided from the enterprises of the city's construction industry. Amenity premises for the accommodation of builders, with a maximum number of employees of 24 people, are provided from temporary inventory buildings. The total duration of construction, taking into account the work of the preparatory period, is 4 months. Construction waste generated during the construction of the building is removed by a specialized organization to a licensed solid waste landfill. The requirements for the organization of the construction site, labor protection and hygiene of construction work, methods of construction work, methods of instrumental control over the quality of construction, labor safety measures, and environmental conditions are met in full. The use of materials and mechanization specified in the project is justified by calculations and conditions for the production of work.