Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Car wash project for 3 posts

Technical and economic indicators

Plot area, ha: 0,3939

Building area, m2: 200,5

Total area of the car wash building, m2: 200,5

Useful area of the washing building, m2: 195,7

Construction volume of the washing building, m3: 945,0

Car wash capacity, vehicles/day: 66

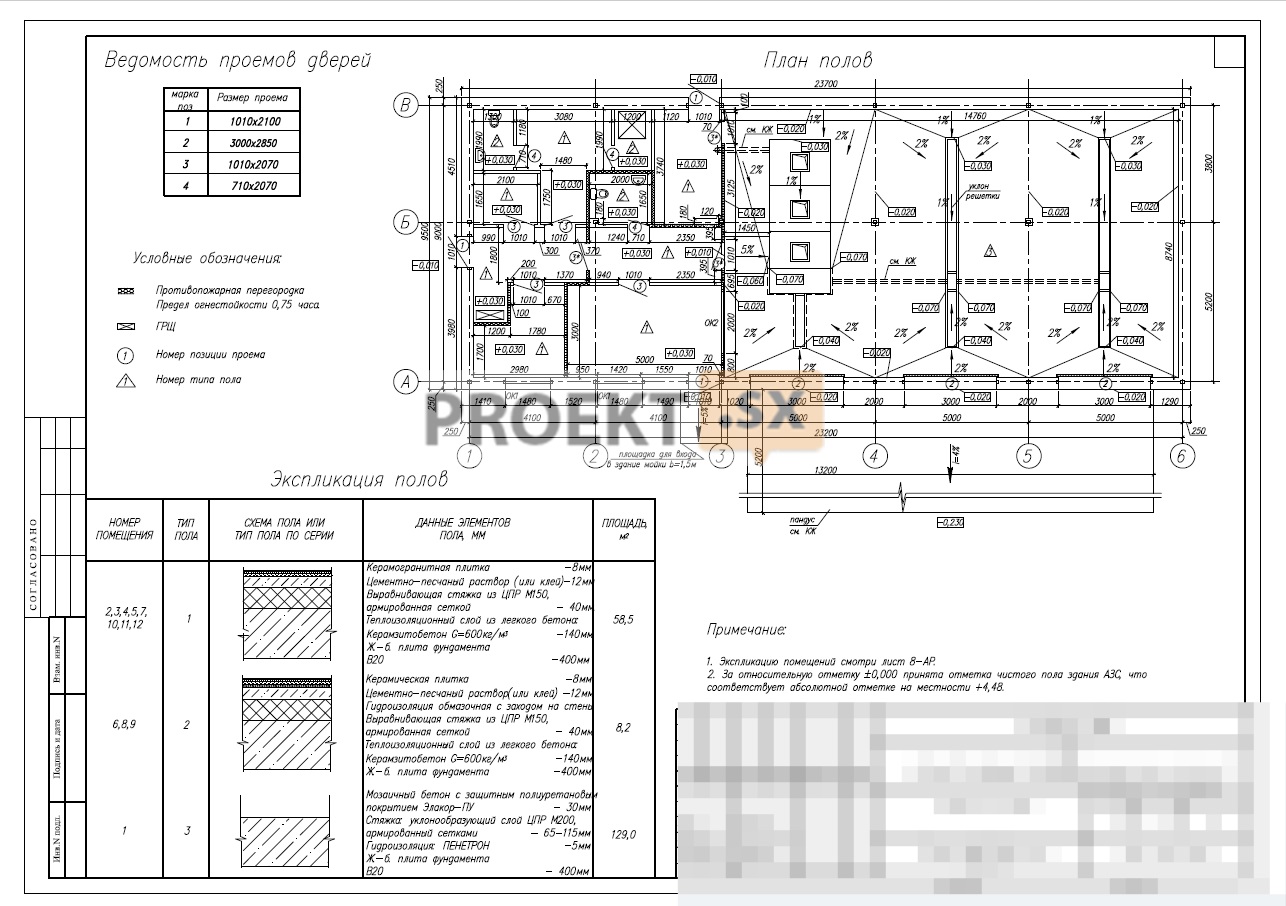

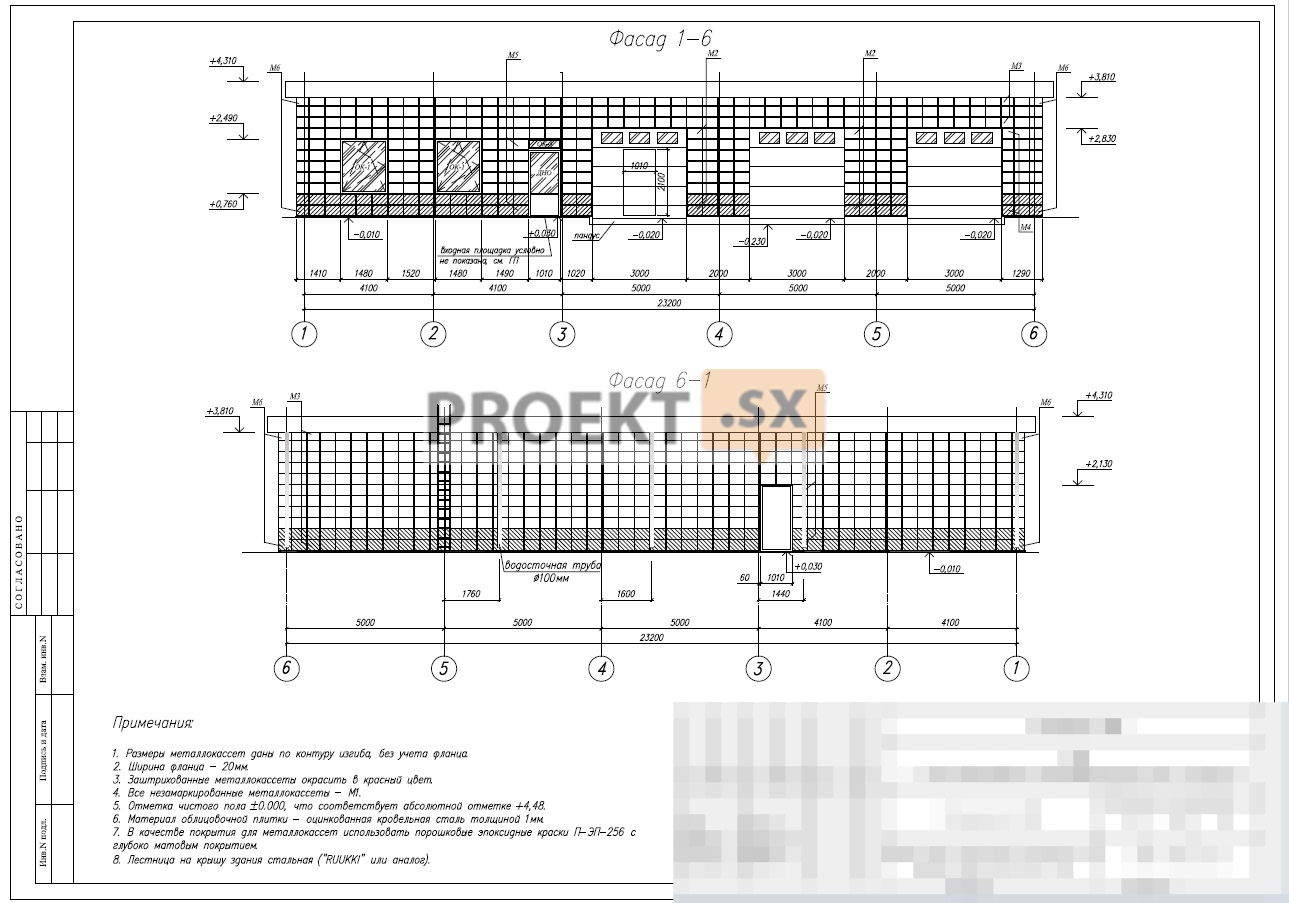

Architectural solutions

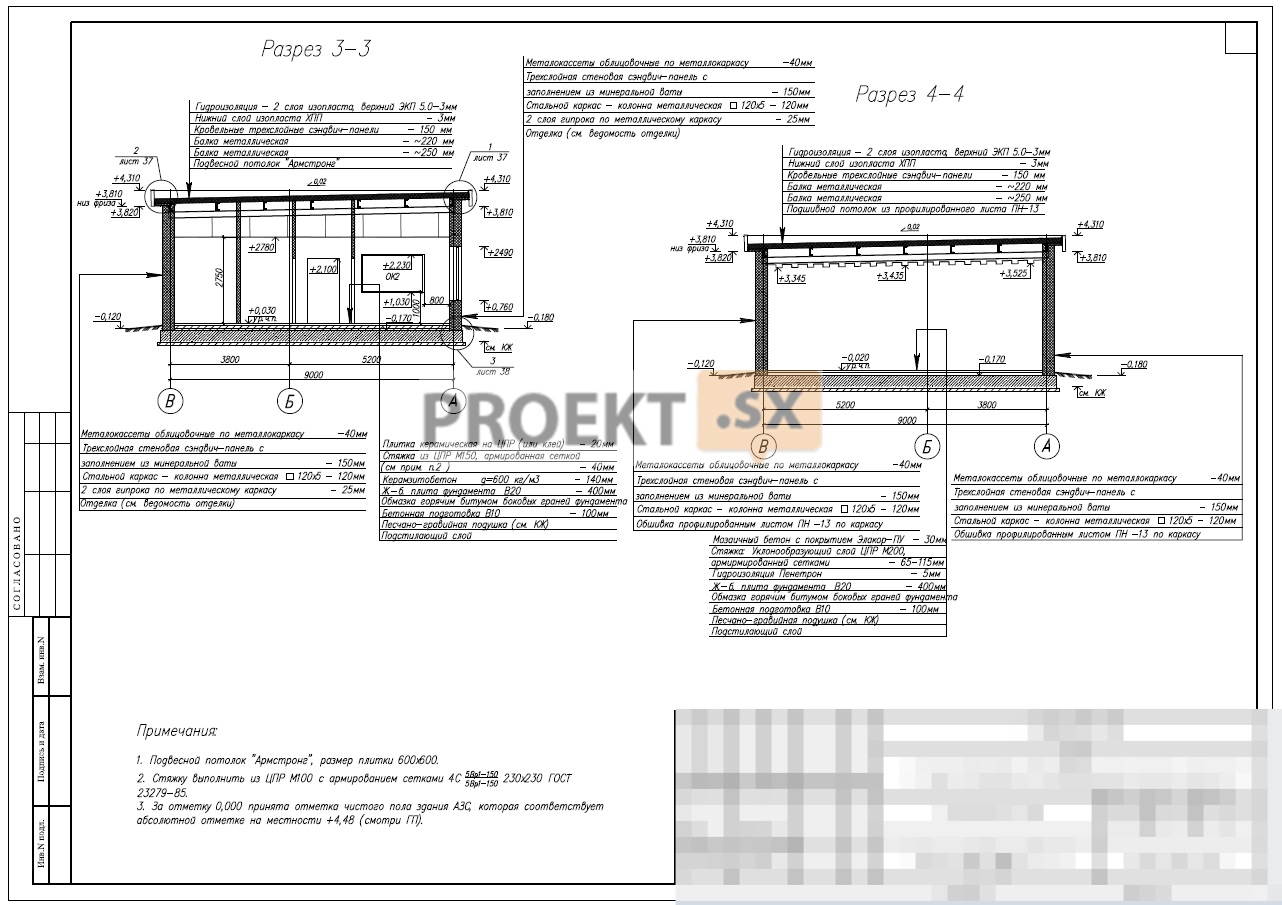

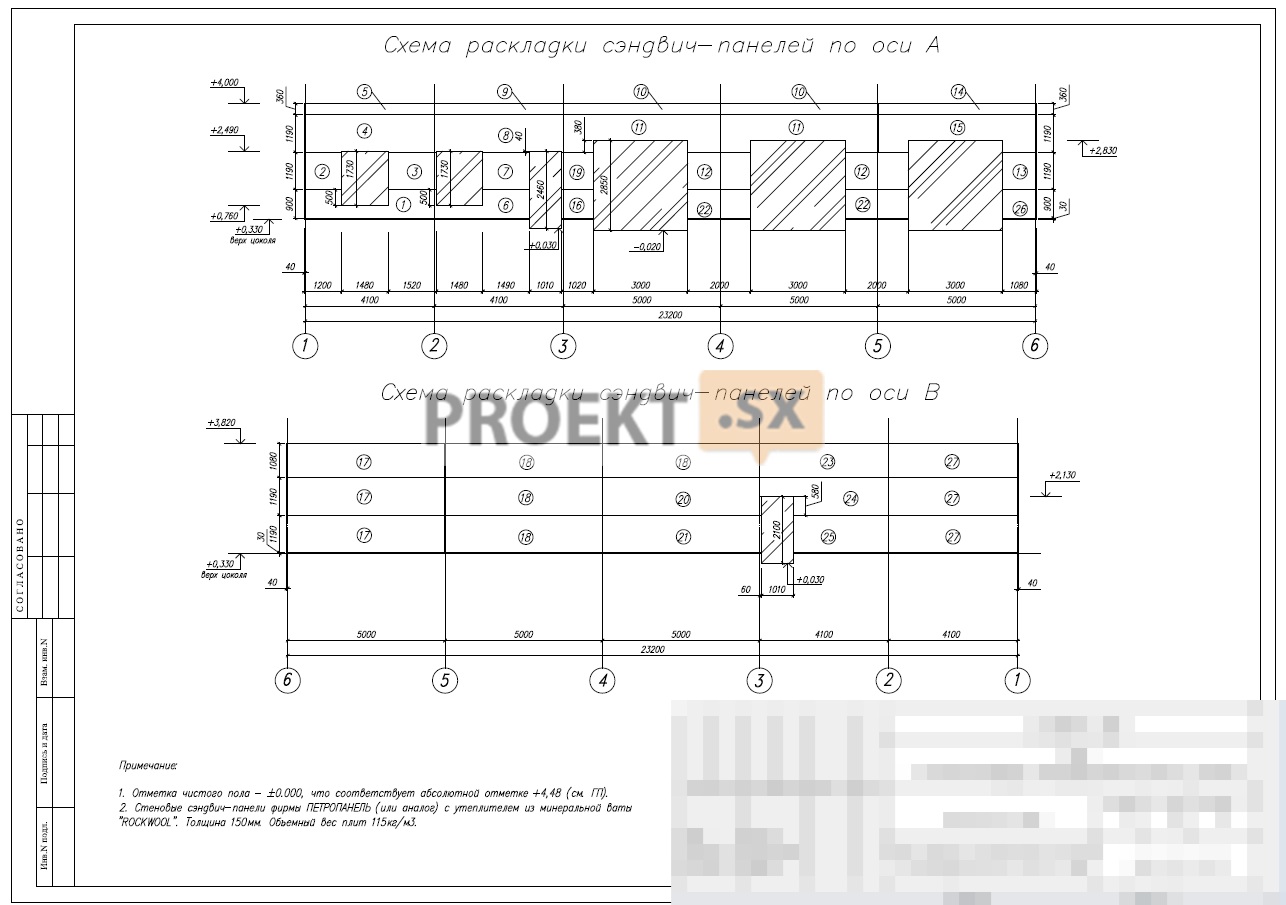

The car wash building for 3 posts is a one-story building, the foundation of which is a monolithic reinforced concrete slab with a built-in water collection pit (for collecting and treating process wastewater), and the supporting frame is made of metal elements of a rolled and welded profile. Enclosing structures - wall and roof sandwich panels. In terms of space planning solutions, the washing building is divided into 3 blocks: production (washing and technological equipment rooms), a block of rooms for visitors, a block of rooms for staff. The constructive scheme of the building is frame-bonded. The load-bearing columns of the building are made of steel bent closed welded square profiles. Vertical and horizontal half-timbered steel bent closed welded square and rectangular profiles. I-section steel beams were used as the supporting structures of the coating. Rigidity and stability of the frame in the longitudinal and transverse directions is ensured by the joint work of columns fixed in the foundation slab, longitudinal and transverse vertical braces of the frame and horizontal braces of the cover. The junction of the beams to the columns is assumed to be hinged. Roofing three-layer sandwich panels along metal purlins made of steel beams were used as a covering for the washing building. They are fastened to the supporting structures with the help of roofing screws. The design scheme of the structure is a frame with rigid pinching of columns at the base and hinged coupling of columns and crossbar. The cover of the hinged group is sheet steel on a metal crate made of rectangular pipes. Landscaping and landscaping of the car wash area involves restoring the lawns around the car wash, as well as paving the area in accordance with the main traffic routes.

Constructive decisions

The frame of the washing building for 3 posts. The constructive scheme of the building is frame-bonded. The load-bearing columns of the building are made of steel bent closed welded square profiles. Vertical and horizontal half-timbered steel bent closed welded square rectangular profiles. I-section steel beams were used as the supporting structures of the coating. Rigidity and stability of the frame in the longitudinal and transverse directions is ensured by the joint work of columns fixed in the foundation slab, longitudinal and transverse vertical braces of the frame and horizontal braces of the cover. The junction of the beams to the columns is assumed to be hinged. Roofing three-layer sandwich panels along metal purlins made of steel beams were used as a covering for the car wash building for 3 posts. They are fastened to the supporting structures with the help of roofing screws. The design scheme of the structure is a frame with rigid pinching of columns at the base and hinged coupling of columns and crossbar. The foundation of the building is a monolithic reinforced concrete slab (concrete B20 F150 W6), 400 mm thick, with embedded parts for the building frame columns and a built-in reinforced concrete pit (size: 2600 mm x 2000 mm x 5000 mm HxWxD), pit wall thickness 250 mm. Under the foundation, concrete preparation is provided with a thickness of 100 mm (concrete B10).

Technological solutions

Washing technology. The car, entering the washing station, is pre-wetted with a sprayed jet of recycled water using cleaning solutions. After wetting, for a sufficient effect of the cleaning agent, a time of the order of 1-3 minutes is required, depending on the degree of contamination. From polished surfaces, a jet of water cannot wash off the smallest dust particles well enough, which are held in a thin water film, and when it dries, they leave a matte coating on the surface. As a result, when washing a car, the mechanical action of special brushes is necessary with the supply of cleaning solutions to the brushes first, and then water. Recycled water is used to wash the car. High pressure washing time t=4 min, mechanical washing time t=5 min. After washing, rinse the car with a spray jet of clean water. Time t=1-2 min. Thus, the total washing time for one car is approximately 15 minutes. Please note that when cleaning car surfaces, the impact pressure should not exceed 1 bar. To do this, the jet gap (the distance between the washing gun and the surface of the car) should be 20-40 cm. For the smooth operation of the cleaning plant, it is necessary to use a shampoo that decomposes in water. The water in the system is replaced based on the washing capacity, guided by a visual assessment of contamination, but at least once a year. Washing vehicles is a process using water, therefore, high humidity and temperature, the finishing of the premises must be carried out based on the condition that undesirable changes may occur in the washing room. For interior decoration it is recommended to use: for the floor: ceramic tiles; for walls: ceramic tiles, at a height of at least 2 meters from the floor, use moisture-resistant paint above the level of the tiles; for the ceiling: moisture resistant paint.