Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Car wash project for trucks for 2 posts

Technical and economic indicators

Building area: 462.59 m2

Number of posts: 2 pcs.

Dimensions in extreme axes: 21.00 x 17.50 m

Building volume: 2585.69 m3

Estimated cost of construction: 23389,05 thousand rubles. (according to the consolidated calculation in prices as of the 3rd quarter of 2017)

Technical and economic indicators

Building area, m2: 462.59

Total building area, m2: 424.10

Usable area, m2: 405.39

Estimated area, m2: 309.22

Construction volume, including m3: 2585.69

below 0.000, m3: 36.0

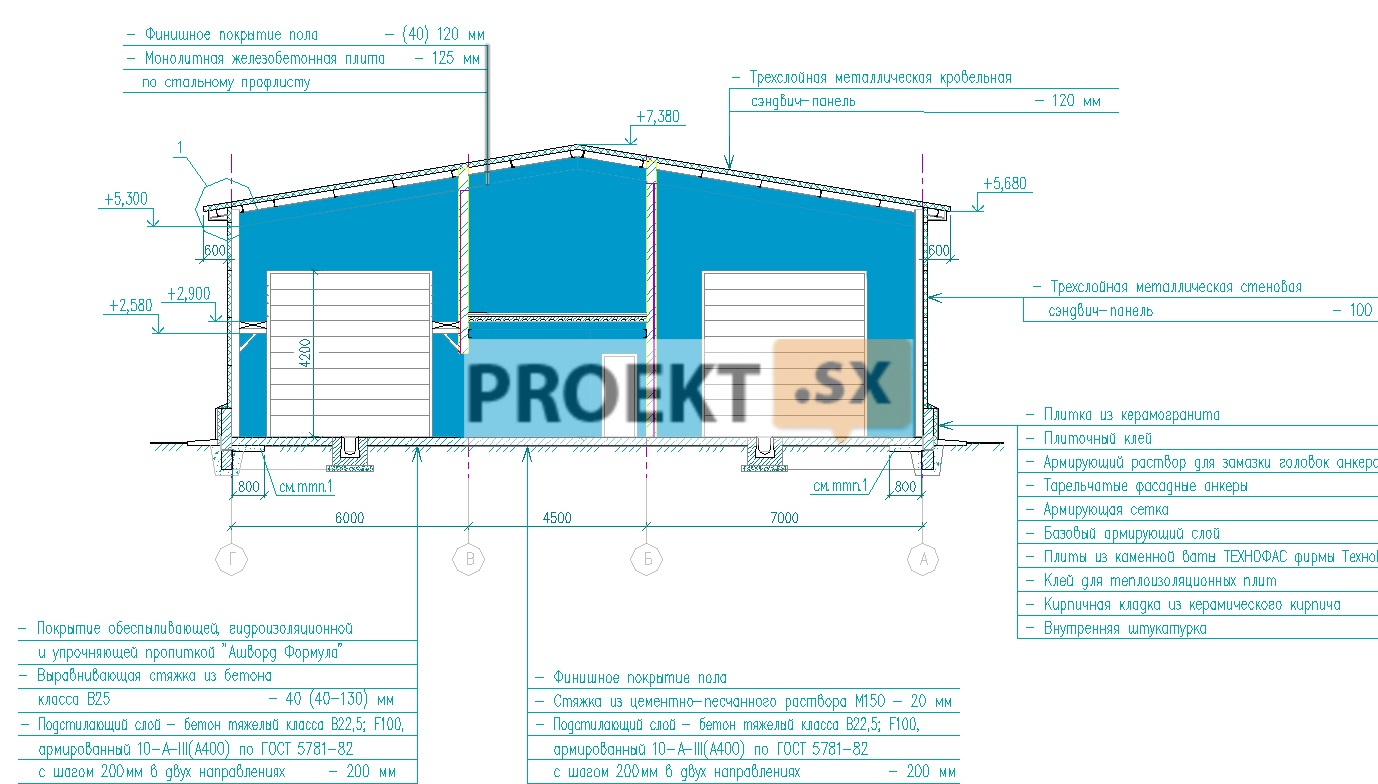

Architectural solutions

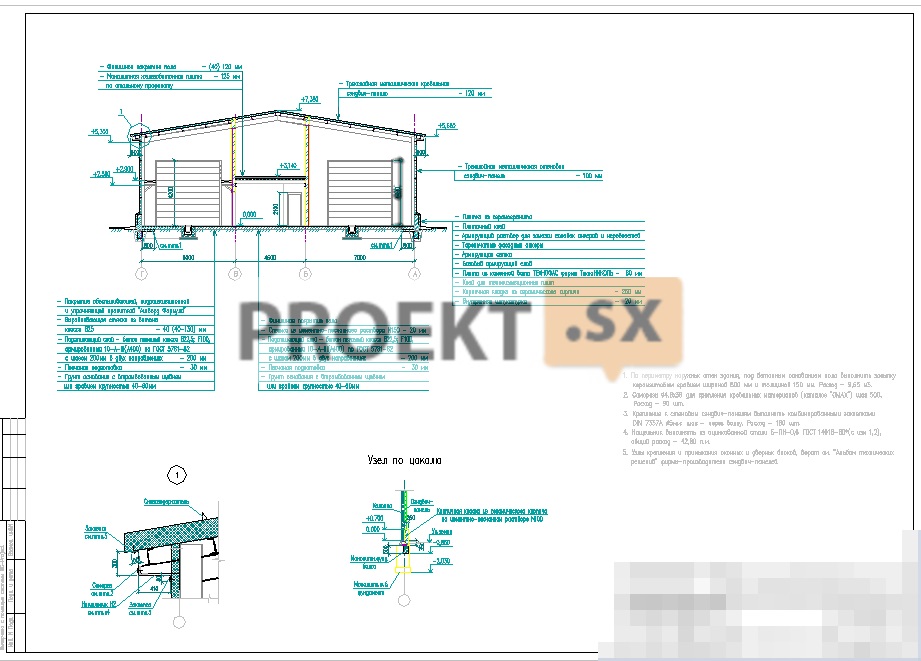

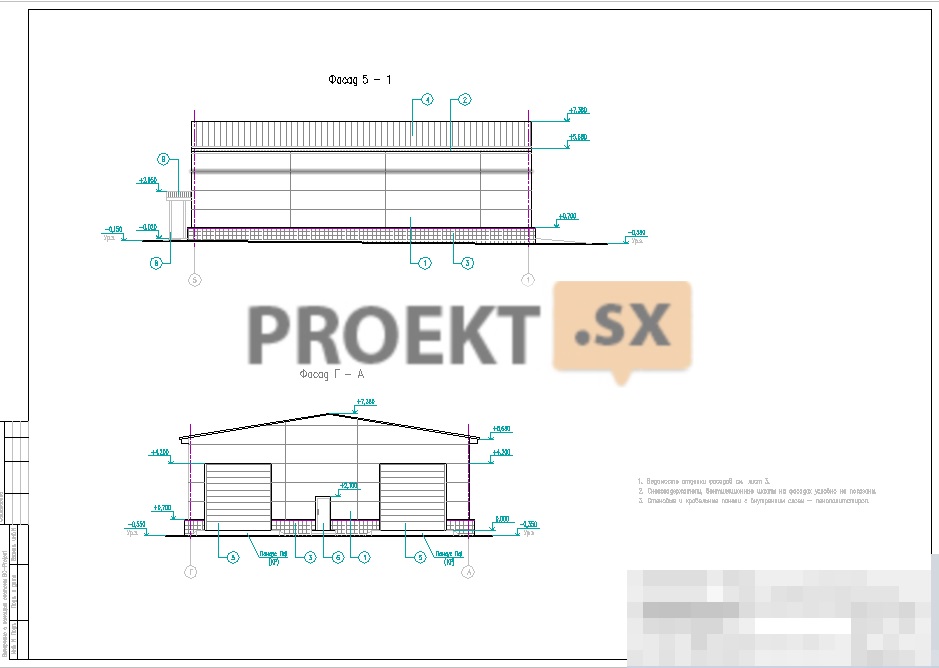

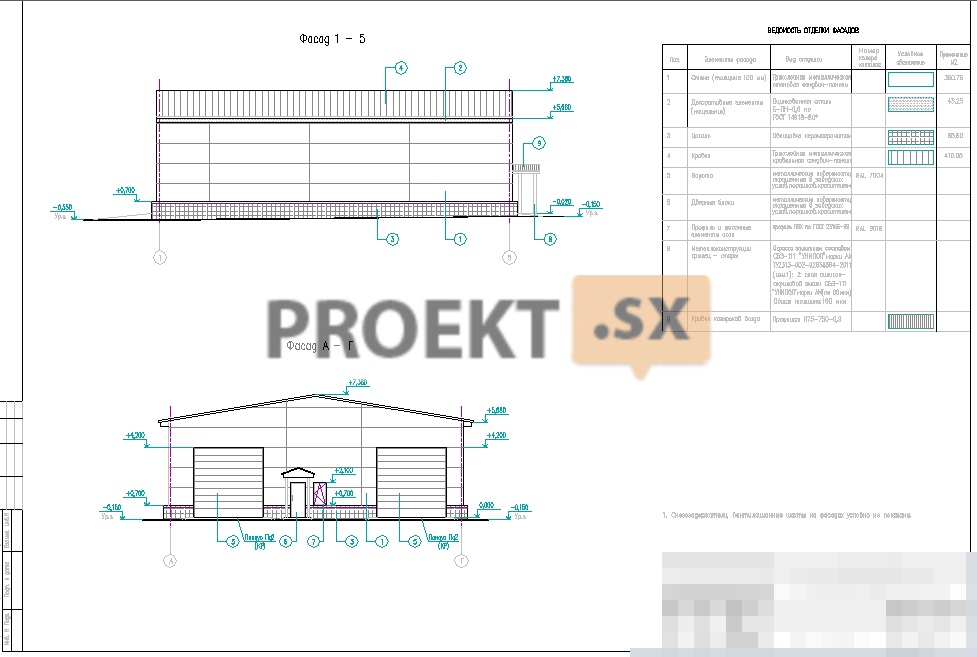

The building is intended for washing trucks, cars and special vehicles during the summer and winter periods of operation. The design is based on the principle of zoning premises that meets technological and hygienic requirements, in accordance with norms, rules and technical regulations. The car wash is a complex of automated equipment that provides portal contact (post N1) and manual washing (post N2) of trucks, cars and special vehicles. The projected volume is a one-storey detached heated frame building with a steel frame. The enclosing structures of the washing building provided for by the project are three-layer metal wall and roof panels. From el. -0,350 elev. +0,700 external walls are made of ceramic bricks with effective insulation and subsequent finishing with porcelain stoneware. The building is equipped with engineering equipment in accordance with the design assignment and regulatory requirements. The architectural, compositional and stylistic solution in the project is determined by modern principles of organizing the urban environment in specific urban conditions. The dimensions of the building are 21,00 m x 17,50 m, the height of the pitched roof ridge is 7,38 m. All washing rooms are located on the 1st floor and on the mezzanine allocated for ventilation chambers. The height of the premises is not the same: sinks, given the pitched roof, variable - from 5,83 m to 6,76 m; premises located in the space under the deck - 2,90 m; ventilation chambers - from 3,67 m to 4,13 m. On the 1st floor there are: washing rooms (post N1 and post N2); compressor room; switchboard; operator's room; pantry; bathroom; dressing room with shower; drivers room. Ventilation chambers are located in the mezzanine level. The project provides for one technological staircase leading from the level of the first floor to the mezzanine. At elev. +2,900 along the axes Г and В, technological metal bridges were made to ensure the process of washing vehicles. The washing operation mode is one-shift with an 8-hour working day, 250 days a year. The designed building belongs to the IV degree of fire resistance; the level of responsibility is normal, in accordance with Federal Law No. 384 "Technical Regulations on the Safety of Buildings and Structures". Functional fire hazard class - F 5.1. Fire hazard class of building structures - KO. Constructive fire hazard class - CO. The nature of the architectural and artistic solution of the facades of the building is due to its purpose. The exterior finish of the walls is the factory coating of sandwich panels. The plinth, to a height of 700 mm, is finished with porcelain stoneware slabs. Window blocks - profile - PVC, color - white, filling - double-glazed window. The roof is made of three-layer metal roofing sandwich panels. The color scheme of the facades is reflected in the "Passport of the color scheme of the facades". The decoration of walls, ceilings and floors is adopted taking into account sanitary, fire, building codes and requirements, as well as depending on the functional purpose of the premises. On evacuation routes (corridor), all finishing materials comply with the requirement of Federal Law No. 123 (Table 28) for buildings with a functional fire hazard class F5.1 - for finishing corridor walls and ceilings - no higher than KM3, floors - KM4. Various types of floor coverings are accepted for finishing the floors of the premises: ceramic tiles in accordance with GOST 6787-2001 - bathrooms, shower rooms, storage rooms, dressing rooms, corridors, ventilation chambers, electrical control rooms, compressor rooms, vestibules, homogenous semi-commercial linoleum in accordance with GOST 18108-80 * - drivers room, operator's room; concrete coating (concrete grade B25) coated with dust-removing, waterproofing and hardening impregnation "Ashword Formula" - a sink room. Ceilings in this building are: factory coating of the inner surface of metal sandwich panels; metal structures of the mezzanine floor, which are covered with a protective composition SBE-111 "UNIPOL" brand AM TU 2313-002-92638584-2011 2 layers, with a total thickness of 160 microns, white color. Improved whitewashing on plaster was made in the vestibule. The following materials are used as finishing materials for walls: cladding with glazed ceramic tiles in washing rooms, bathrooms, shower rooms, pantry, compressor room, switchboard room, ventilation chambers; improved plaster with high quality acrylic paint - in the driver's room, control room, dressing room, corridors. According to SanPiN 2.2.1/2.1.1.1278-03 (as amended. dated March 15, 2010) the calculation of the coefficient of natural light at this facility is not required. The premises provided for by the project with a permanent stay of people are located isolated from the technical premises. Ventilation chambers are located in the mezzanine volume above the premises without permanent stay of people. In technical rooms, the following measures are taken to ensure protection against the harmful effects of noise: installation of low-noise equipment; installation of noise silencers with a ventilation system; selection of the optimal equipment mode; the use of “floating floors” in ventilation chambers (noise-insulating slabs SHUMOSTOP C2 (K2) are used as sound insulation - 2 mats 20 mm thick, gasket VIBROSTEK-M around the perimeter of the room). The whole complex of these activities will be reflected in the sections of the working documentation. The project was carried out in accordance with the requirements of the norms SP 23-103-2003 "Design of sound insulation of enclosing structures of residential and public buildings", SP 51.13330.2011 "SNiP 23-03-2003. Noise protection. To protect the premises from moisture penetration, all walls in contact with the ground are made with waterproofing, which is used as TECHNONIKOL mastic N 33 TU 5775-045-72746455-2010 .4 mm thick, profiled membrane PLANTERSTANDART TechnoNIKOL thickness. 8 mm. Horizontal insulation is made with a cement-sand mortar with a composition of 1: 2 (1 part - cement, 2 parts - sand). Drainage of rain and melt water from the building is carried out on a hard asphalt concrete pavement (see Fig. ROM kit). The design of the floors of the compressor room, bathroom and shower room provides for a waterproofing layer with an institution on the walls of 300 mm. The decoration of the premises is carried out with ceramic tiles on a cement-sand solution for the entire height of the premises (bathroom, shower room). Finishing floors - also ceramic tiles. The protruding elements of the roof are protected by roofing galvanized steel 0.8 mm thick GOST 14918-80*. The designs of external enclosing structures are adopted in accordance with SP 50.13330.2012 SNiP 23-02-2003 "Design of thermal protection of buildings" based on an internal temperature of +18 ° C (clause 5.2) .

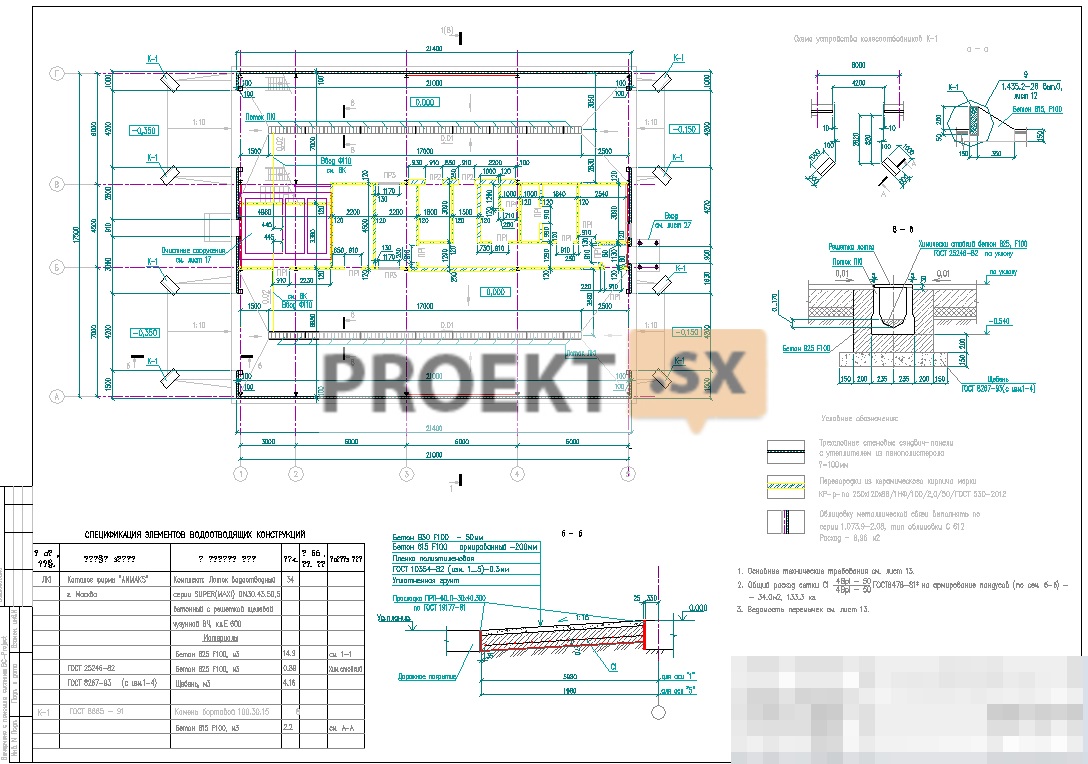

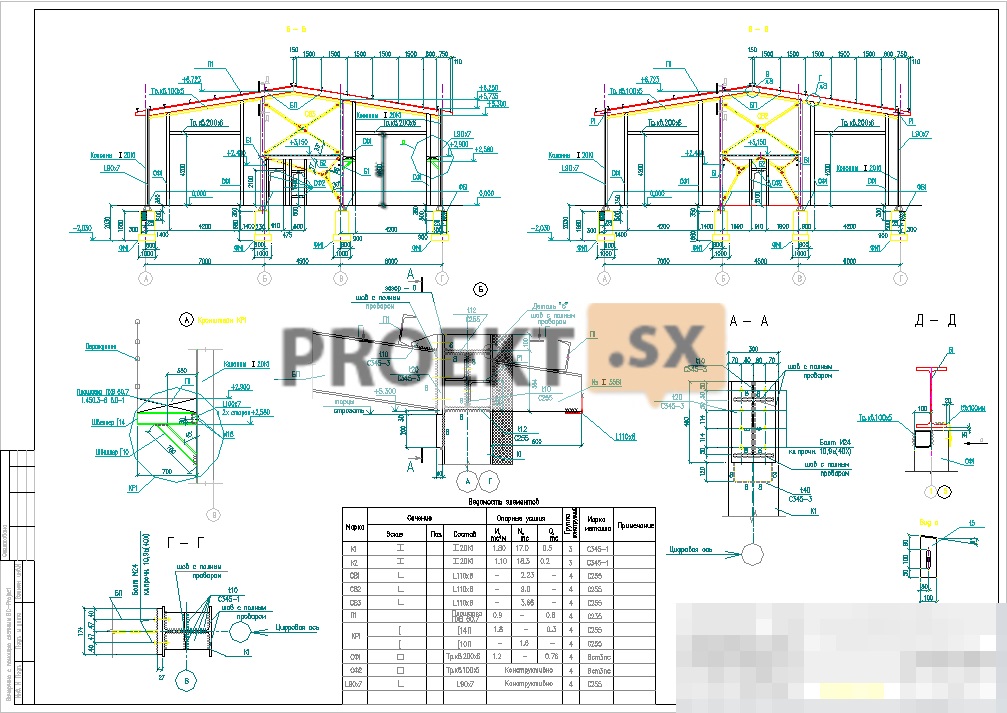

Constructive decisions

The building of the designed car wash is rectangular in plan, the overall dimensions along the extreme axes are 21.0x17.5m. Building with a steel frame, single-span, covered with steel beams, the lower elevation of the beams is 5.3m. In the middle part of the building, the 2nd floor is built in, with dimensions in terms of 21.0x4.5m, with technical rooms, made in a steel frame, with monolithic reinforced concrete ceilings on fixed formwork. The stability of the building is ensured by the rigid embedding of the columns in the foundations connected by monolithic reinforced concrete beams; a system of vertical and horizontal steel ties; rigidity of the frames and the floor disk of the built-in floor connected with the main frame of the building. External walls - from three-layer metal panels "Belpanel" type C4 according to TU 5284-003-54655944-2004 with expanded polystyrene insulation. Internal walls - from ceramic brick KR-r-po 250x120x88 / 1.4NF / 100 / 2,0 / 25 GOST 530-2012 on cement-sand mortar M100. Stair flights and landings - steel according to series 1.450.3-7.94 Roof - from three-layer metal panels "Belpanel" type K4 according to TU 5284-003-54655944-2004 with expanded polystyrene insulation. Structural solutions below el. 0.000. According to the IGI data, the basis of the designed foundations is: EGE-2, white-yellow sand, fine, medium density, low degree of water saturation with the following design characteristics: fp = 31оС, С ii = 0.01 kg/cm2; pp \u1,69d 3 g / cm230, E \u2d XNUMX kg / cmXNUMX. Underground waters for the survey period were found at a depth of 7.5-8.0m. Soils are not aggressive to concrete and reinforced concrete. The normative depth of freezing of sandy soils is 1.7 m. The foundations of the building - free-standing columnar monolithic reinforced concrete - for columns and monolithic reinforced concrete. foundation beams - under the brick base and internal diaphragm walls, rigidly connected to the foundations. In the middle span, monolithic reinforced concrete structures are provided. sewage treatment plant - sump. The above-ground part of the building is made in a steel frame. The step of the columns along the digital axes is 3 and 6 m, along the alphabetic axes - 4.5, 6 and 7 m. The columns of the main frame and the frame of office frames - solid, continuous, are made of rolled I-beams (columns) according to STO ASCHM 2093. The connection of columns with foundations is rigid. Column bases are made from one base plate welded to the column rod and stiffeners. The columns are fixed to the foundation with anchor bolts directly behind the slab. Beams: Joints of beams with columns of external axes are rigid, between themselves and supports on internal columns are hinged. Beams - solid continuous are made of a rolling I-beam according to STO ASCHM 20-93. Overlapping (of the built-in floor) - reinforced concrete on corrugated board. Spacers for columns - from paired rolled equal-shelf angles in accordance with GOST 8509 - 93. Wall fachwerk - from bent-welded square sections in accordance with GOST 30245-2003. Connections for columns and trusses - from single rolled equal-shelf angles in accordance with GOST 8509 - 93. Roof purlins - continuous continuous ones are made of a channel according to GOST 8240-97. The invariability of the coating in the horizontal plane is ensured by a solid disk formed by three-layer steel roofing panels, fixed on the purlins with self-tapping screws and a system of horizontal ties and spacers (purlins) - along the roof beams. The wind load from the ends of the building is transmitted, through horizontal connections and runs, to vertical connections between the columns. Steel structures are designed in accordance with the requirements of the following regulatory documents: SNiP 2.01.07-85* Loads and impacts; SNiP II-23-81* Steel structures. Design standards; SNiP 2.03.11-85 Protection of building structures against corrosion. In this project, the following types of metal structures have been developed: columns, trusses, floor and roof beams, roof girders, vertical ties on trusses, vertical and horizontal ties on roof trusses. Steel grade of columns C345-1, other elements C255 in accordance with GOST 27772-88 *: Material of gussets, overlays, ribs, etc.