Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Boiler house project 15 MW

Design, working documentation, including estimates, and the results of engineering surveys for the construction and reconstruction of heat supply facilities. Construction of a boiler house and reconstruction of heating networks.

Technical and economic indicators

Installed capacity of the boiler house: 12,9 Gcal/h (15 MW).

Land area, ha: 0,0421

Building area, m2: 273,67

Total building area, m2: 242,0

Construction volume of the building, m3: 1041,07

Length of engineering networks, including, lm: 3211,4

Heating networks, running meters: 2687 (5374,4 in one-pipe terms)

Water supply networks, lm: 62,0

Water disposal networks, lm: 27,5

Power supply networks, lm: 153,0

Gas supply networks, lm: 44,50

Communication networks, pm: 237,4

Estimated cost at the 2001 base price level (without VAT)

Total: thousand rubles: 36061,22

Construction and installation works, thousand rubles: 11432,15

Equipment, thousand rubles: 20829,51

Other expenses, thousand rubles: 3799,56

including :

PIR, thousand rubles: 1845,53

refundable amounts, thousand rubles: 239,91

Estimated cost at current price level August 2011 (VAT included)

Total: thousand rubles: 158331,45

Construction and installation works, thousand rubles: 61571,20

Equipment, thousand rubles: 76440,15

Other expenses, thousand rubles: 20320,10

including:

PIR, thousand rubles: 8129,00

VAT, thousand rubles: 23973,10

refundable amounts, thousand rubles: 1304,75

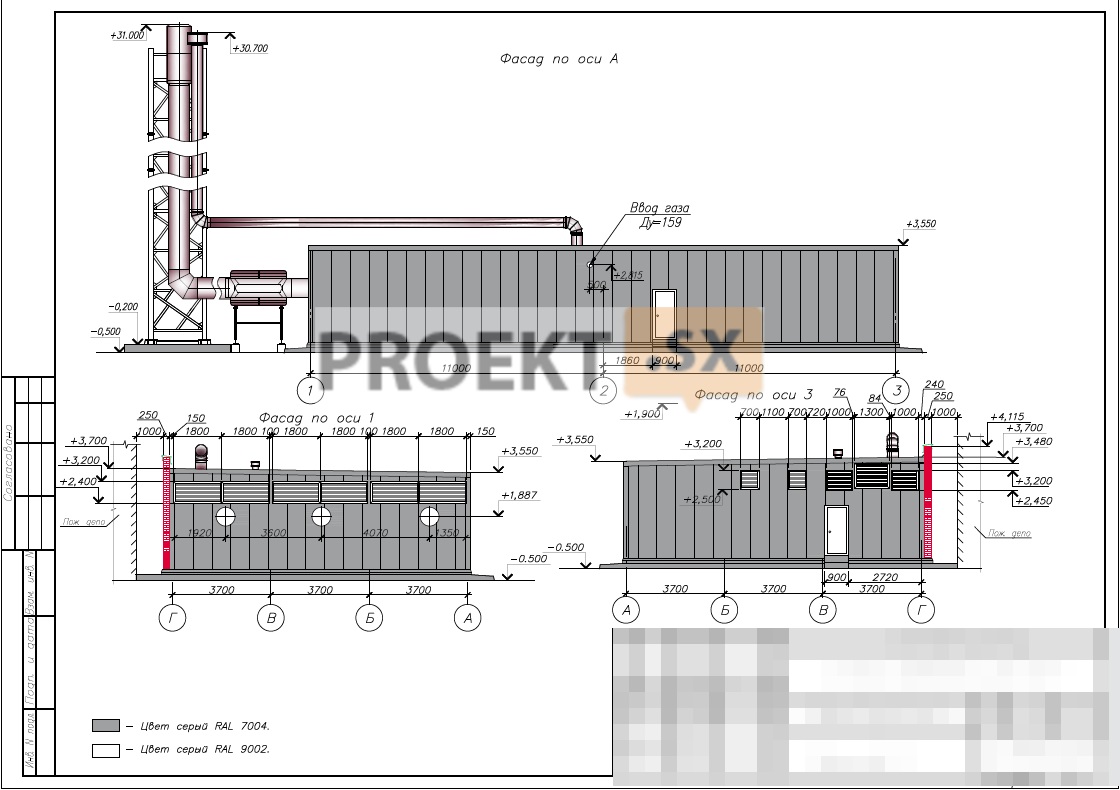

Architectural and space-planning solutions

The boiler house building is a detached, one-story, rectangular configuration in plan, with a total size in the axes of 22,00x11,00 m. The height of the building from ground level to the top of the roof is 4,05 m. For the relative mark of 0,000, the level of the finished floor of the first floor, corresponding to the absolute mark of 8.52 m, was taken. The boiler house building is a one-story frame building structure, formed from the modules of the automated modular boiler house "Signal 15000", installed on a monolithic reinforced concrete slab foundation with a boiler room and a diesel generator room located in it. The frame of the building is metal structures. Facade finishing: Walls - multi-layer wall panels with an inner layer of insulation made of mineral wool boards and outer surfaces made of metal profiled painted sheet. The roof is flat, made of rolled waterproofing materials, with an external organized drain. Doorways are provided to provide access to the boiler room. An extension of a 250 mm thick fire-prevention brick wall is provided for the building of the boiler house along the G axis. A chimney was designed near the boiler house building, which is a spatial metal structure with three gas ducts 31,00 m high.

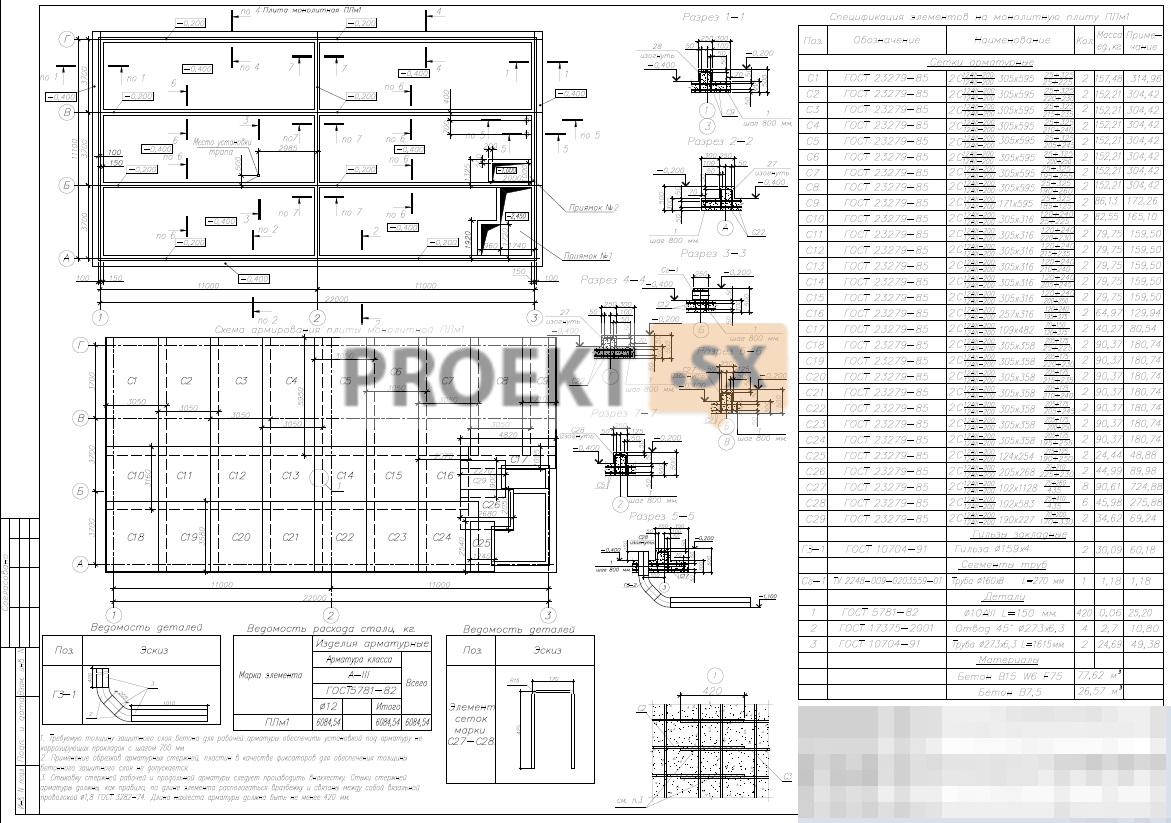

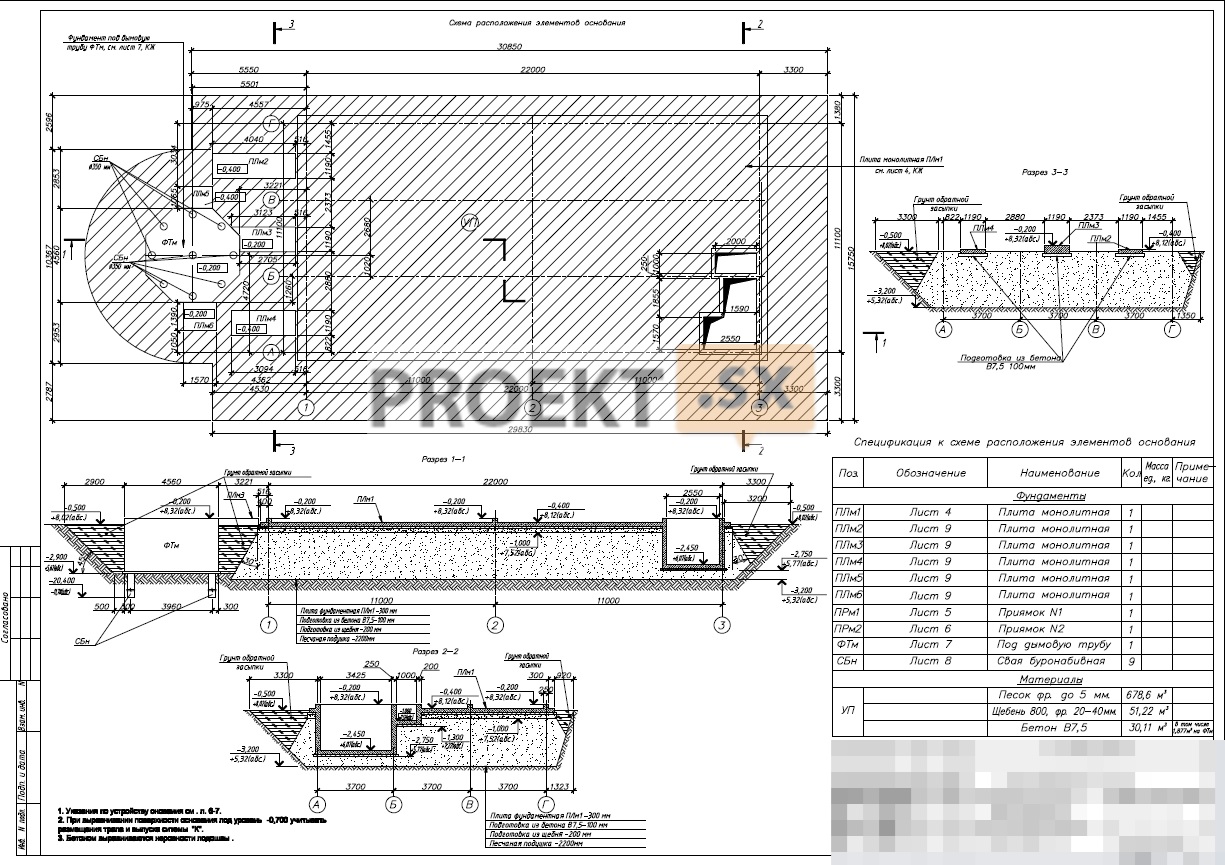

Structural and space-planning solutions

The modular boiler house is designed from easily assembled metal structures with "sandwich" paneling. Metal structures are made of a closed bent profile 80x4, etc. (connections from a bent profile 60x5) according to GOST 30245-2003. Base of beam I-beams 20B1 according to STO ASCHM 20-93 and channels 16P, 20P according to GOST 8240-97. Steel C245. External walls - hinged "sandwich" panels 100 mm thick. The coating is made of "sandwich" panels 100 mm thick on a metal frame. The spatial rigidity and stability of buildings is ensured by the joint work of metal racks, vertical and horizontal connections and a hard disk of the coating. The foundations are taken in the form of a monolithic reinforced concrete slab 300 mm thick with ribs 500x250 mm, concrete B15, W6, F75. A 100 mm thick concrete preparation is provided under the foundation. The chimney 31 m high (3 flues with an outer diameter of 700 mm) are fixed on a spatial metal structure installed on its own foundation. The foundations for the pipe are piled. Bored piles with a diameter of 350 mm and a length of ~20 m, concrete B25, W6, F75. Column grillages made of concrete B25, W6, F75. The relative elevation of 0.00 corresponds to the absolute elevation of +8,52 m. In accordance with the report on engineering and geological surveys, the base of the sand cushion is coarse and gravelly, loose sands (after compaction provided for by the design documentation) with E=300 kg/cm2, φ=35, c=1 KPa. The design resistance of the foundation soils is not lower than R=3,52 kg/cm2. The pressure on the ground does not exceed p=0,194 kg/cm2. The base of the piles are hard-plastic loams with IL=0.46, φ=21, c=25 kPa, E=12 MPa. The maximum level of groundwater per abs. elevations of 5,5 m. Groundwater is non-aggressive to concrete of normal permeability. In order to protect the concrete of underground structures, the concrete grade for water resistance is W6, the concrete surface is protected by coating with MBR-65 mastic. The expected average settlement of the building is no more than 1,2 cm. The stability of the pipe is ensured. Technical inspection of buildings of the surrounding development (3 buildings, residential building at 26-28 Voronezhskaya Street, letter A, at a distance of 12 m from the projected boiler house (category 3), building on Ligovsky pr., 149, lit. H at a distance of 18 m (category 2), building along Voronezhskaya street, 28 building 1 at a distance of 12 m) (category 3).

Engineering equipment, utility networks, engineering activities

The design documentation provides for the connection of existing residential, public and administrative buildings to the designed boiler house in accordance with the list of the targeted program agreed and approved by the management for long-term development and investment. The total total connected heat load (without losses) is 7,841 Gcal/h, including 7,822 Gcal/h for heating and 0,019 Gcal/h for technology. The same, taking into account losses in networks (7%) - 8,389 Gcal / h, including for heating - 8,369 Gcal / h and technology - 0,020 Gcal / h. The category of reliability of heat supply to all consumers of thermal energy is the second. The construction of the designed free-standing heating boiler house is envisaged on the site of the existing boiler house to be demolished. The heating system is two-pipe. The heat carrier at the outlet of the boiler room is water with a temperature of 95-700C. In accordance with the location of the connected buildings relative to the boiler house, 4 outlets of heating networks are provided from the latter. Laying of heating networks from the boiler house to the ITP - underground channelless, in impassable channels at the corners of the route and under the carriageway; in cases and along existing and non-existent routes through the basements of buildings. Entrances to buildings - through steel sleeves with stuffing box seals and sealing units. Laying of heating networks under the roads - on a solid concrete pad with a mortgage metal sheet. Pipes for underground laying, in accordance with the Design Assignment: DN > 125 mm - electric-welded steel GOST 10704-91 gr.V Art. 20 GOST 1050-88 in industrial PPU-PE insulation with ODK GOST 30732-06; DooBoiler room - detached, heating, automated, gas. In accordance with the Design Assignment, consumers of thermal energy are connected to the boiler house according to the address list with a total heat load, taking into account losses (7%) - 8.389 Gcal / h, and the prospective heat load is taken into account - 3,389 Gcal / h. The total heat load on the boiler house, taking into account the consumption for auxiliary needs of the boiler house, is 11,896 Gcal/h (13738 kW). In terms of reliability of heat supply to consumers, the boiler house belongs to the second category. Three water-heating boilers Termotekhnik TT of 5000 kW each manufactured by Entroros LLC were accepted for installation. The installed capacity of the boiler house is 12,9 Gcal/h (15 MW). In accordance with the Terms of Reference, the boilers are equipped with GKP-500 M combined burners with DMV-D multiblocks and the Wise Drive 100 control system. The boiler room equipment is controlled by the following systems: - Entromatic 50.1 - control of the operation of three boilers in a cascade, burners depending on the load, controls the heating circuit; Entromatic 50.2 controls the boiler circuit and Entromatic 50.3 controls the network circuit. Boiler operation mode - constant temperature at the outlet of the boiler - 1100 and control over the temperature at the inlet to the boiler. The limits of boiler power regulation are 25 - 100%. The boiler room is double-circuit. 1st circuit - boiler 110-750C; the second - network 95-700C. Connection of the heating system to the heating networks of the boiler circuit - through two (one - reserve) heat exchangers of the M15-MFM type from Alfa Laval with network pumps IL100 / 170. Heat carrier temperature control according to the temperature schedule - three-way valve type MHF32F in front of the heat exchangers, temperature sensor type TP1 on the network water behind the heat exchangers, outdoor air temperature sensor type GTS and Entromatic control unit. Make-up of the boiler and network circuits - from the household. drinking water supply with preliminary water treatment in a dosing unit type TEKNA APG. Gas consumption for installed capacity - 1752,7 m3/h. The source of gas supply is the existing gas pipeline of medium pressure Du500 mm. At the inlet of the gas pipeline Du150 mm with a pressure of 0,12 MPa, fittings, a filter FN6-1, an electromagnetic valve VN6N-Z, a control damper ER6-6 PR, a gas metering unit based on a gas meter STG-150-1000 are installed. On the branches to the boilers - fittings, a mesh filter, a gas pressure regulator of the Norval-375-G-SN type with a built-in shut-off valve, a PSK of the VS / AM type. The boiler room is provided with an automatic powder fire extinguishing installation. The boilers are equipped with automation, control, regulation and safety systems. The gas supply to the boiler room is turned off when: increasing or decreasing gas pressure in front of the burners; lowering the air pressure in front of the burners; extinguishing the torch; increase or decrease in water temperature at the outlet of the boiler; with an increase or decrease in water pressure at the outlet of the boiler; in the event of a power failure. networks; at the second threshold of gas contamination of the room with methane or carbon monoxide; in case of fire. Removal of combustion products during gas combustion - through individual heat-insulated chimneys with stainless steel gas ducts, equipped with silencers, explosion valves, hatches, condensate drains and fittings for connecting gas analyzers. Water supply and sanitation - in accordance with the conditions of connection. Water supply (cold water) for consumers of the facility is provided through two water inlets with a diameter of 110 mm from the public water supply network with a diameter of 221 mm on the street. Polyethylene pipes according to GOST 18599-2001 were selected for laying water inlets. The designed inputs provide for the installation of water measuring units according to the drawings TsIRV 02A.00.00.00, album sheets 50, 51. The guaranteed head at the connection point is 28 meters of water column. Cold water consumption 34,83 m³/day, including: for feeding heating networks - 34,83 m³ / day. Periodic Needs: for wet cleaning of the boiler room - 0,10 m³ / day (1 time per month); for filling heating networks - 224,22 m³ / day (1 time per year); for filling the boiler room system - 30,72 m³ / day (1 time per year). A joint water supply system, dead-end, with ringing of inputs, was designed for the object. Pipes made of corrosion-resistant steel according to GOST 11068-81 were selected for the device of the integrated water supply system. The required pressure for technological needs (filling heating networks) is 44,86 meters of water column. The required pressure for the needs of internal fire extinguishing is 18,68 meters of water column. Water consumption for internal fire extinguishing - 2x2,6 l / s. Number of fire hydrants with a diameter of 50 mm - 2 piece. External fire extinguishing is provided from the existing fire hydrant No. 69, on the public water supply network with a diameter of 221 mm along Voronezhskaya street. Water consumption for external fire extinguishing - 10 l / s. Removal of domestic wastewater in the amount of 0,10 m³/day (1 time per month), process wastewater from the boiler circuit drain in the amount of 30,72 m³/day (1 time per year) there is one release into the on-site industrial sewerage network with discharge of wastewater into well No. 119 on the existing intra-yard communal sewerage network with a diameter of 230 mm. At the outlet from the boiler house, a well with a check valve, a well with a valve and a control well are provided. The drainage of rainwater from the roof and the adjacent territory with a flow rate of 11,07 l / s is provided for in the projected storm water well D1 with a connection to well No. 114 on the yard public sewerage network with a diameter of 230 mm. Polypropylene pipes with a diameter of 160/138 mm and 225/200 mm were selected for laying on-site sewer networks. An industrial sewerage system has been designed for the facility. Cast iron sewer pipes according to GOST 6942-98 were selected for the installation of the industrial sewerage system. The power supply of the boiler house is provided in accordance with the technical specifications. The power allowed for connection is 179,4 kVA according to the III category of reliability. Power source - PS-542. The point of connection to the network is 0,38 kV switchgear of the new transformer substation. The required category of power supply for the electrical receivers of the boiler room is II. As a second source of power supply, in accordance with the terms of reference, a stationary diesel generator set SDMO-V350K Nexys Silent (318 kVA) is provided. Redundant power supply of the automatic control and dispatching system is provided from an independent source - UPS (battery - 1,5 kVA). The estimated recovery time of heat supply to consumers of the boiler house after a power outage from PS-542 is no more than 5 minutes. The power supply scheme adopted in the design documentation does not meet the requirements for the reliability of power supply to consumers of the designed facility in accordance with paragraphs 1.2.19, 1.2.20 of the rules for the installation of electrical installations. Estimated load of the boiler house is 179,4 kVA. To connect a new transformer substation (BKTP) to switchgear-0,38 kV, laying of a cable of the APvBbShp-1kV brand is provided; section: 4x240 mm² from the main switchboard of the boiler room. The cable cross section was checked for long-term permissible load, voltage loss, the condition for disconnecting the damaged section at a single-phase short-circuit current. Consumers of electric power of the boiler house are: electrical receivers of technological equipment, network and circulation pumps, hot water boilers, instrumentation, electric motors of ventilation systems, working, emergency lighting; fire alarm devices; means of communication; Outdoor Lighting.