Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

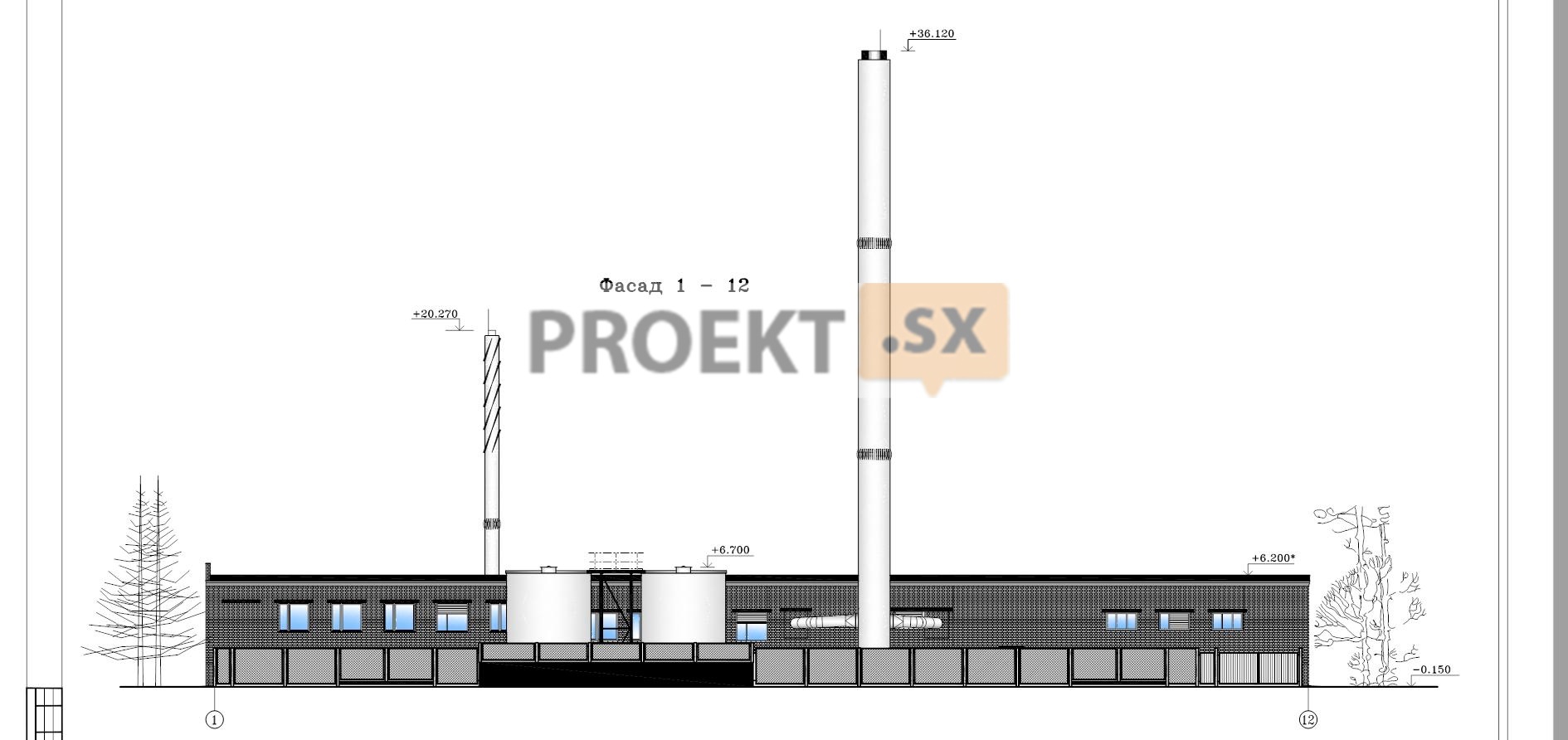

Boiler house project 10,55 MW

Design, working documentation, including estimates, and the results of engineering surveys for the reconstruction of the boiler house

Technical and economic characteristics of the capital construction object

Plot area within the boundaries of the land allotment, m2: 1568,0

Building area, m²: 611,1

Total building area, m²: 662,4

Construction volume, m3: 3245,3

Number of floors, floor: 1

Productivity, MW: 10,55

Estimated cost at the 2001 base price level (without VAT)

Total: thousand rubles: 18830,78

Construction and installation works, thousand rubles: 7771,56

Equipment, thousand rubles: 7237,08

Other expenses, thousand rubles: 3822,14

including:

PIR, thousand rubles: 1685,14

refundable amounts, thousand rubles: 119,54

Estimated cost at the current price level as of August 2010 (including VAT)

Total: thousand rubles: 93821,35

Construction and installation works, thousand rubles: 50208,06

Equipment, thousand rubles: 24509,10

Other expenses, thousand rubles: 19104,19

including:

PIR, thousand rubles: 7411,41

VAT, thousand rubles: 14145,44

refundable amounts, thousand rubles: 575,83

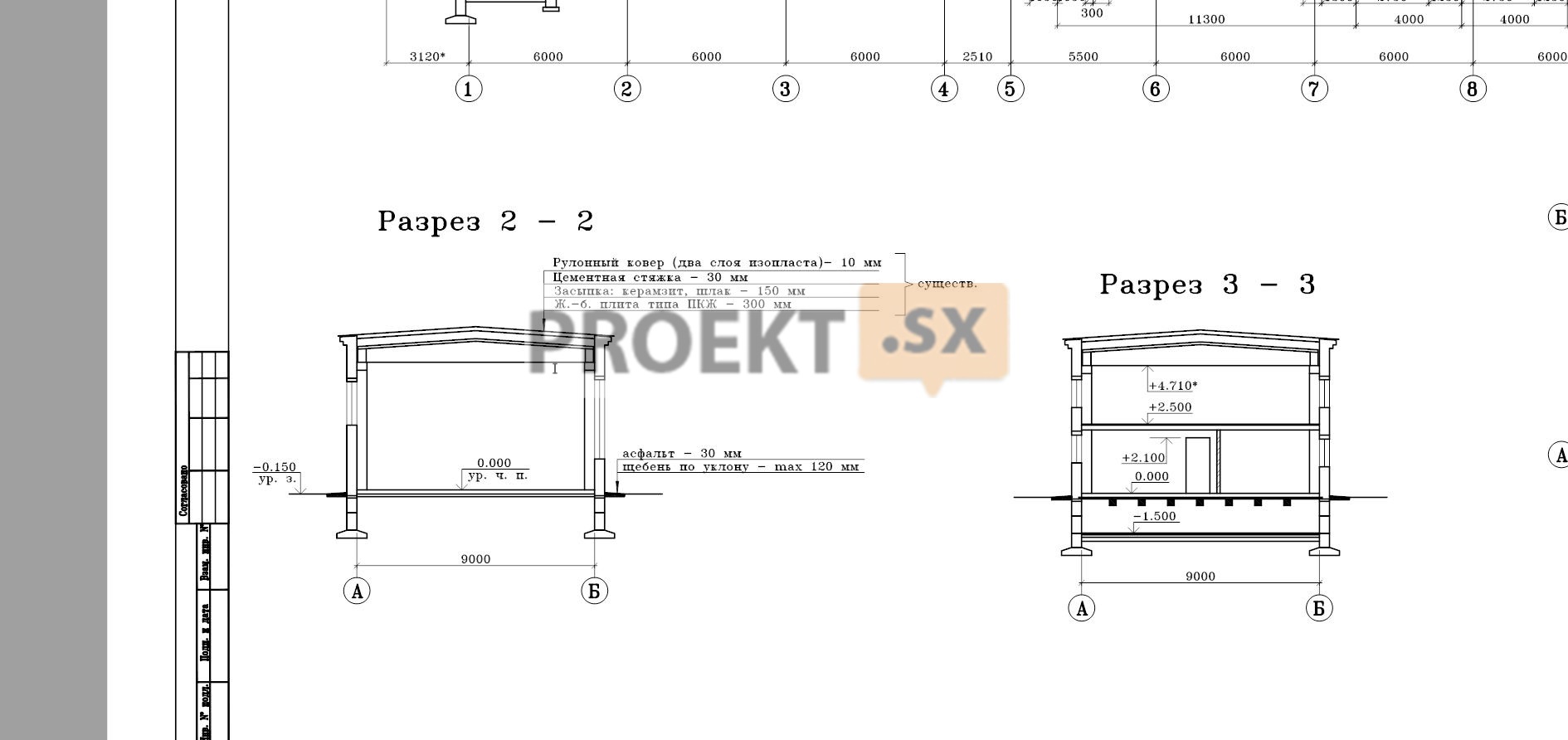

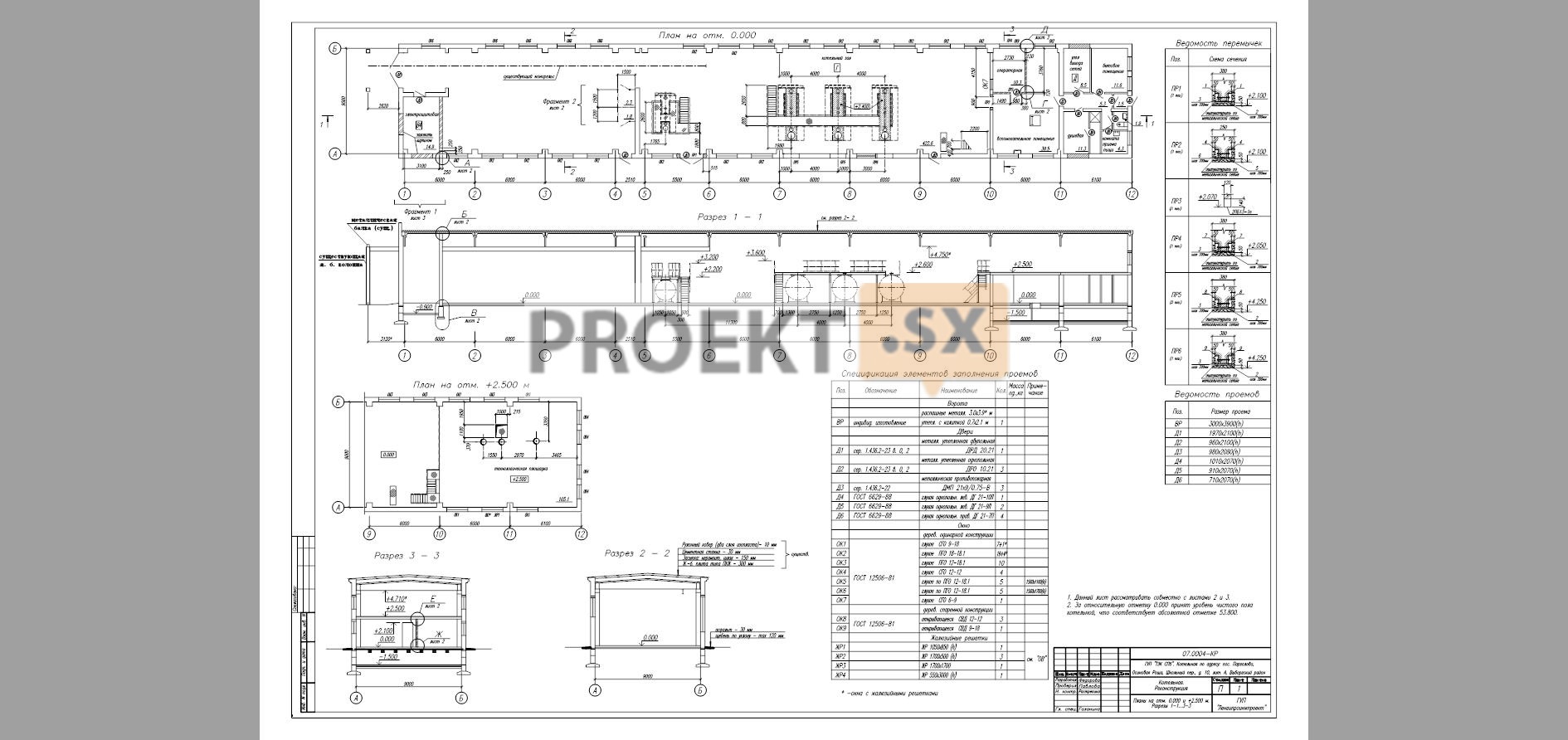

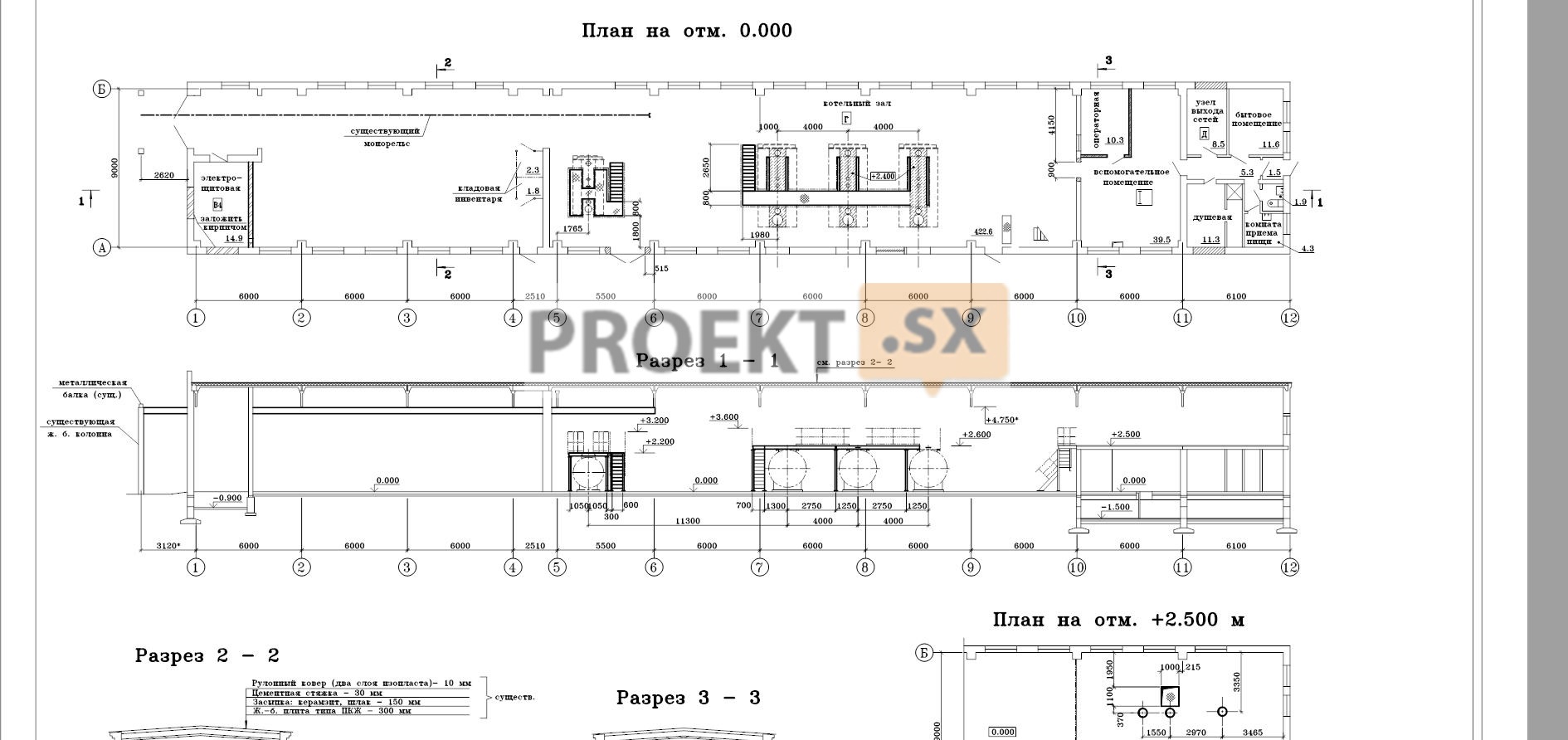

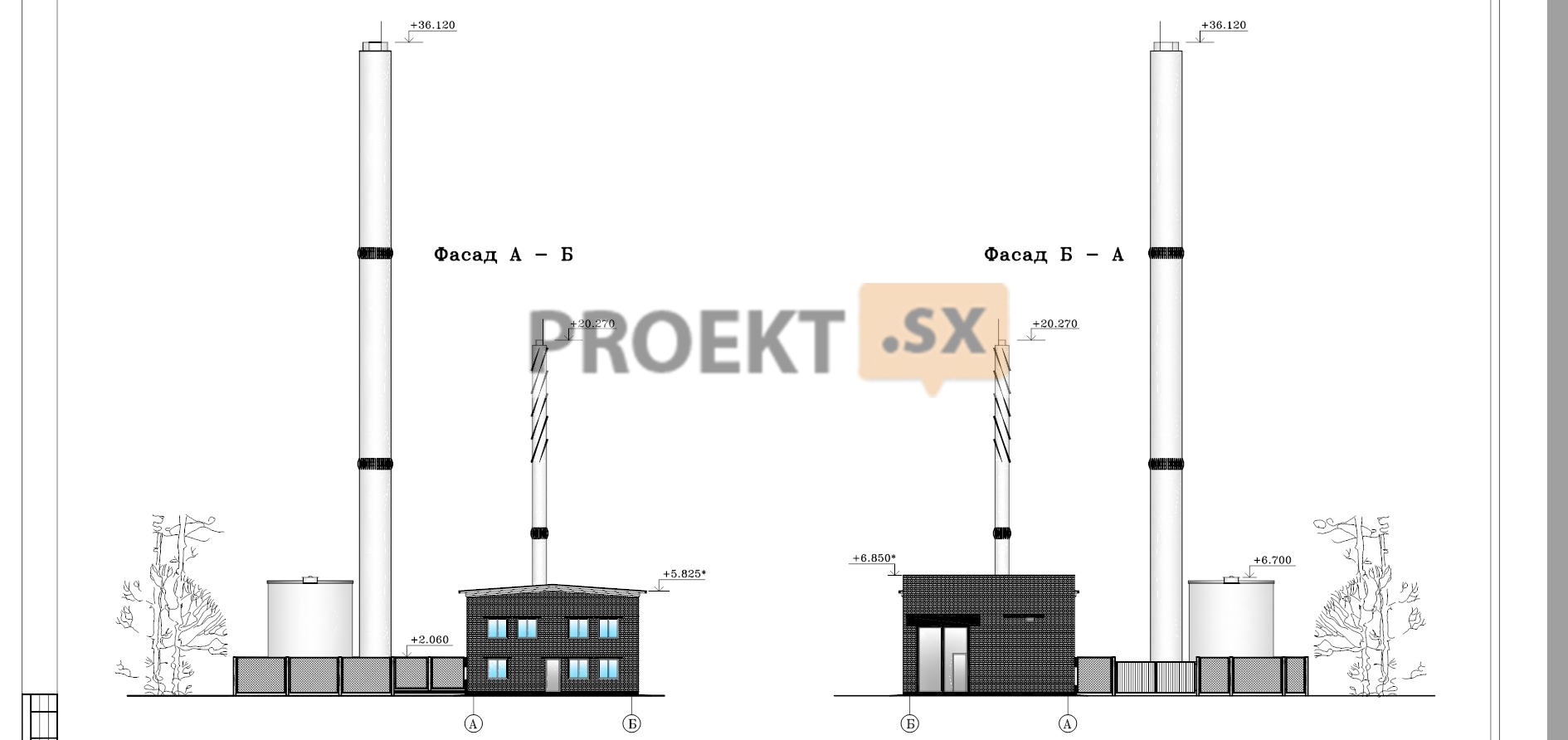

Architectural and space-planning solutions

The project documentation provides for the reconstruction of the boiler house. During the reconstruction, the following is provided: dismantling of the extension in axes 5 - 7 from the side of axis A, replacement of process equipment, placement of an operator and auxiliary premises at the site of the existing pumping station, repair work to eliminate defects in building structures. In the building of the boiler house, the following are designed: a boiler room, an operator room, an electrical panel room, a room for a network entry point, an auxiliary room and utility rooms as part of a shower room, a bathroom, a dining room. The design of the floors is adopted in accordance with the purpose of the premises. In the boiler room, the floors are concrete coated with Siltek organosilicate composition. In the corridor, an auxiliary room, shower room and bathroom - from ceramic tiles, in amenity rooms and the control room - from linoleum. In the switchboard room - from corrugated steel above the underground with a mark of -0,900. For rooms with technological equipment, blind wooden windows with single glazing are accepted; in the sanitary facilities - opening windows with double glazing, the window along axis 10 from the control room to the boiler room is fireproof. In the volume of the boiler room, the design and area of glazing of windows is taken into account taking into account the requirements for the implementation of easily dropped structures for boiler rooms of category G. The area of easily dropped structures is taken at the rate of 0,03 m² per 1,0 m³ of the volume of the room. The building of the boiler house is provided with metal insulated entrance doors and gates. Gates - hinged with a gate 0,7x2,1 m. Doors to the electrical room, control room and area of sanitary facilities - metal fireproof. In the rest of the rooms, solid wooden doors are adopted. The waterproofing carpet of the roof is in good condition and its replacement by the project documentation is not provided. The design documentation provides for the arrangement of an external organized drain through gutters and downpipes. When carrying out the interior decoration of the boiler room, operator room, utility rooms, painting with water-based paints on the plastered surface is provided (after restoring the damaged areas of the plaster layer). The walls of the switchboard are painted with silicate paints. In the premises of the bathroom, shower room and dining room, the walls are lined with ceramic tiles to the height of the doorway. When carrying out exterior finishing, an injection of cement mortar into cracks in the walls to the full depth is provided. On the basement sections of the walls, it is planned to carry out work to restore the destroyed plaster layer and carry out work to repair the blind area. Painting of the outer surface of brick walls is provided by facade paints AKRYL-1 VAK VD-AK-125-1 ONPF "VA-PA" in two layers.

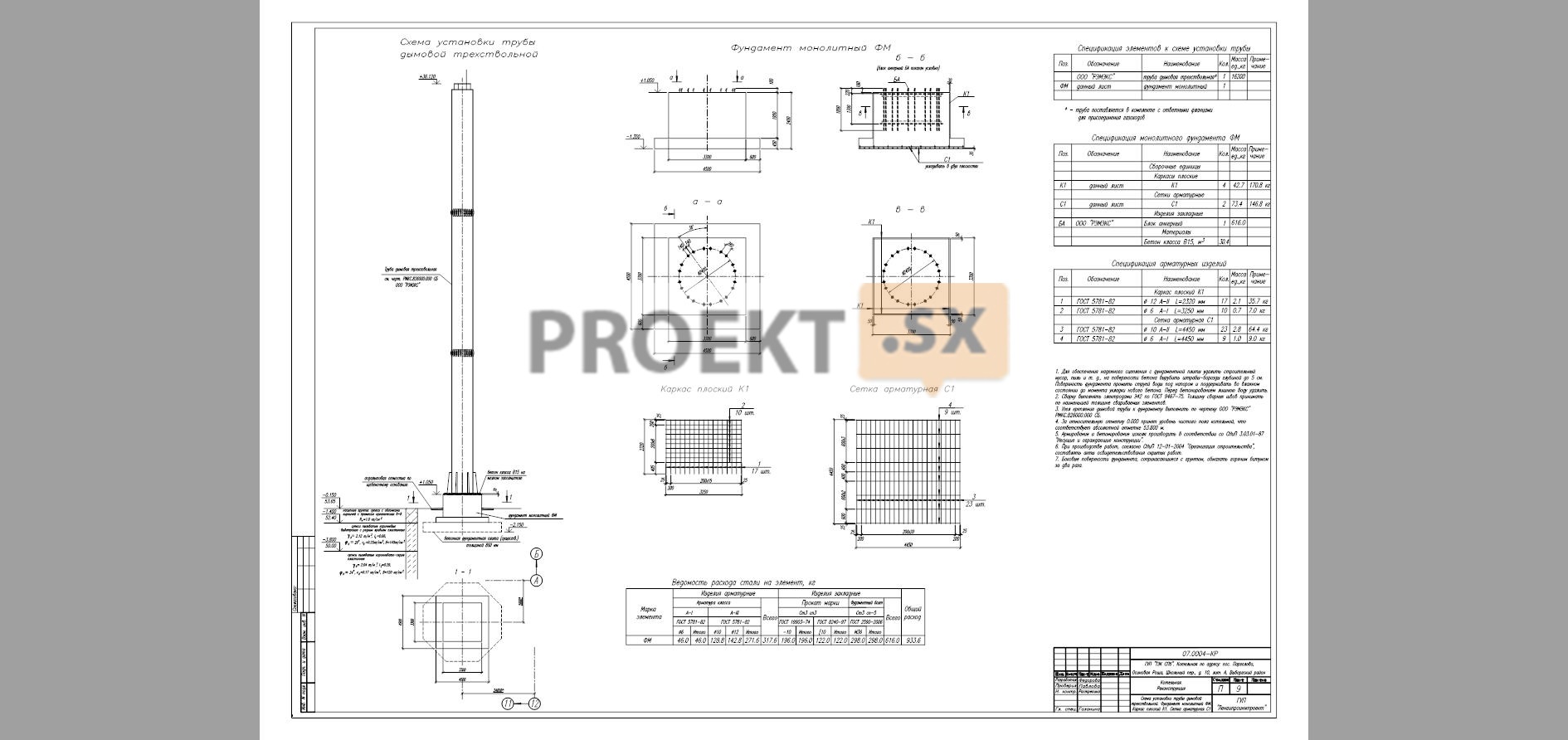

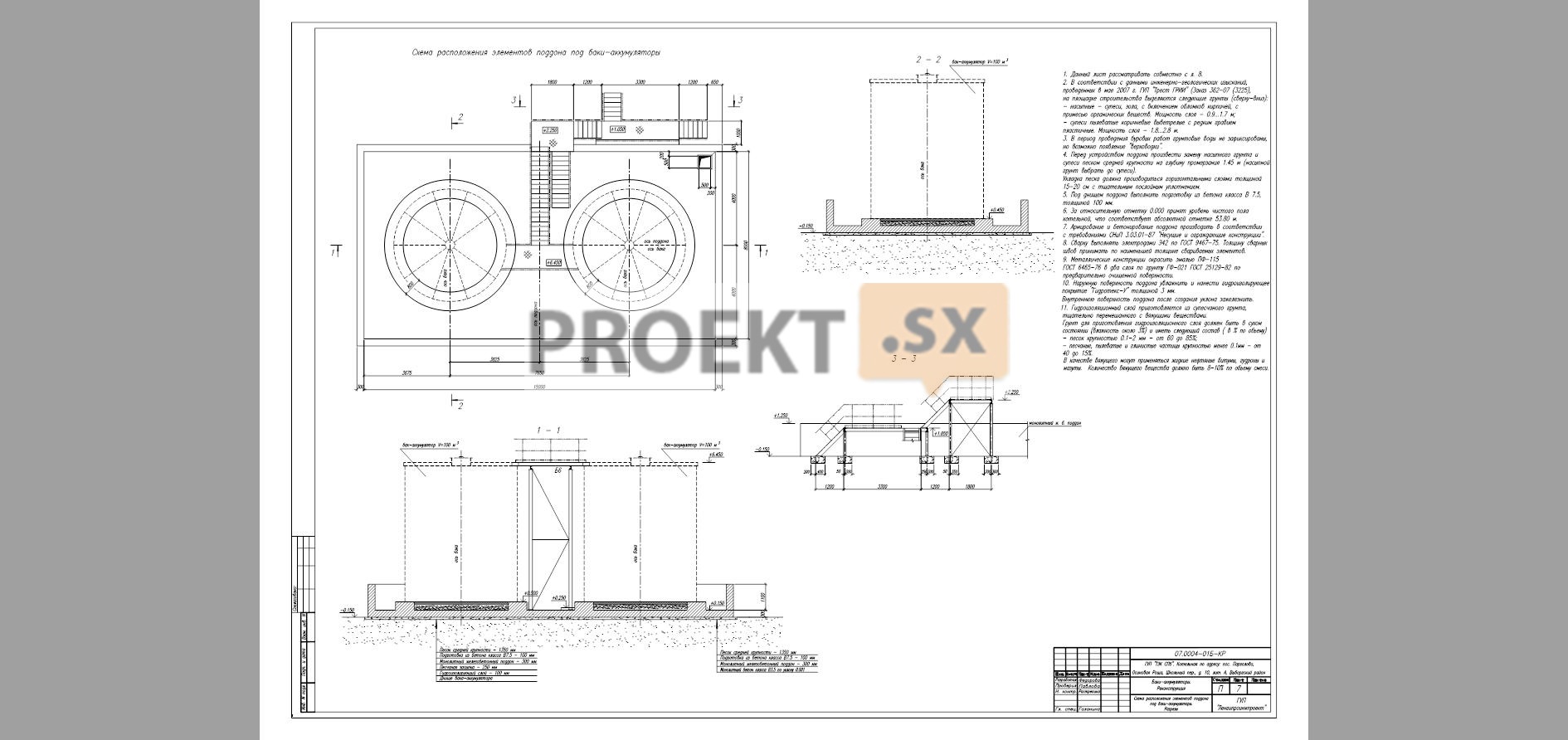

Structural and space-planning solutions

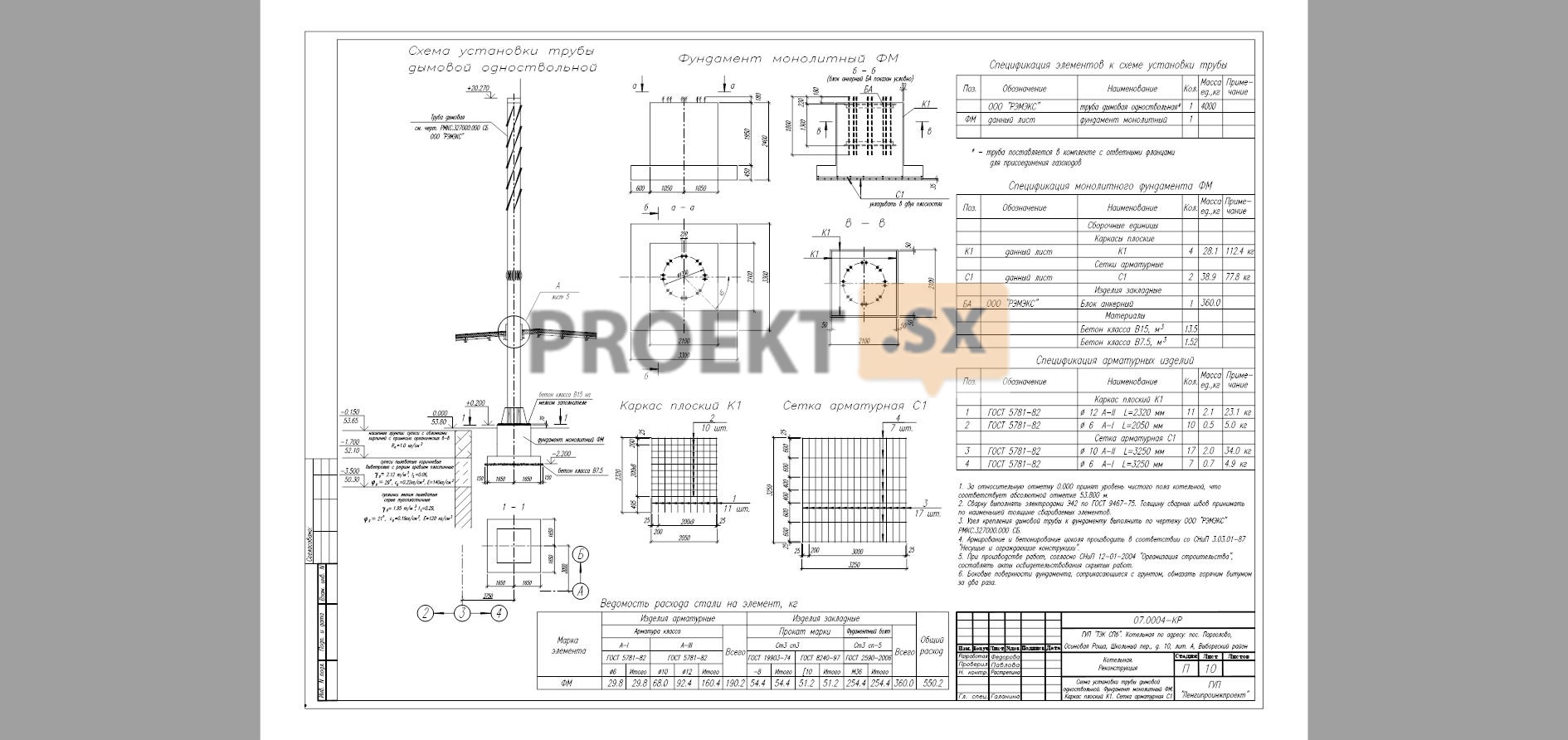

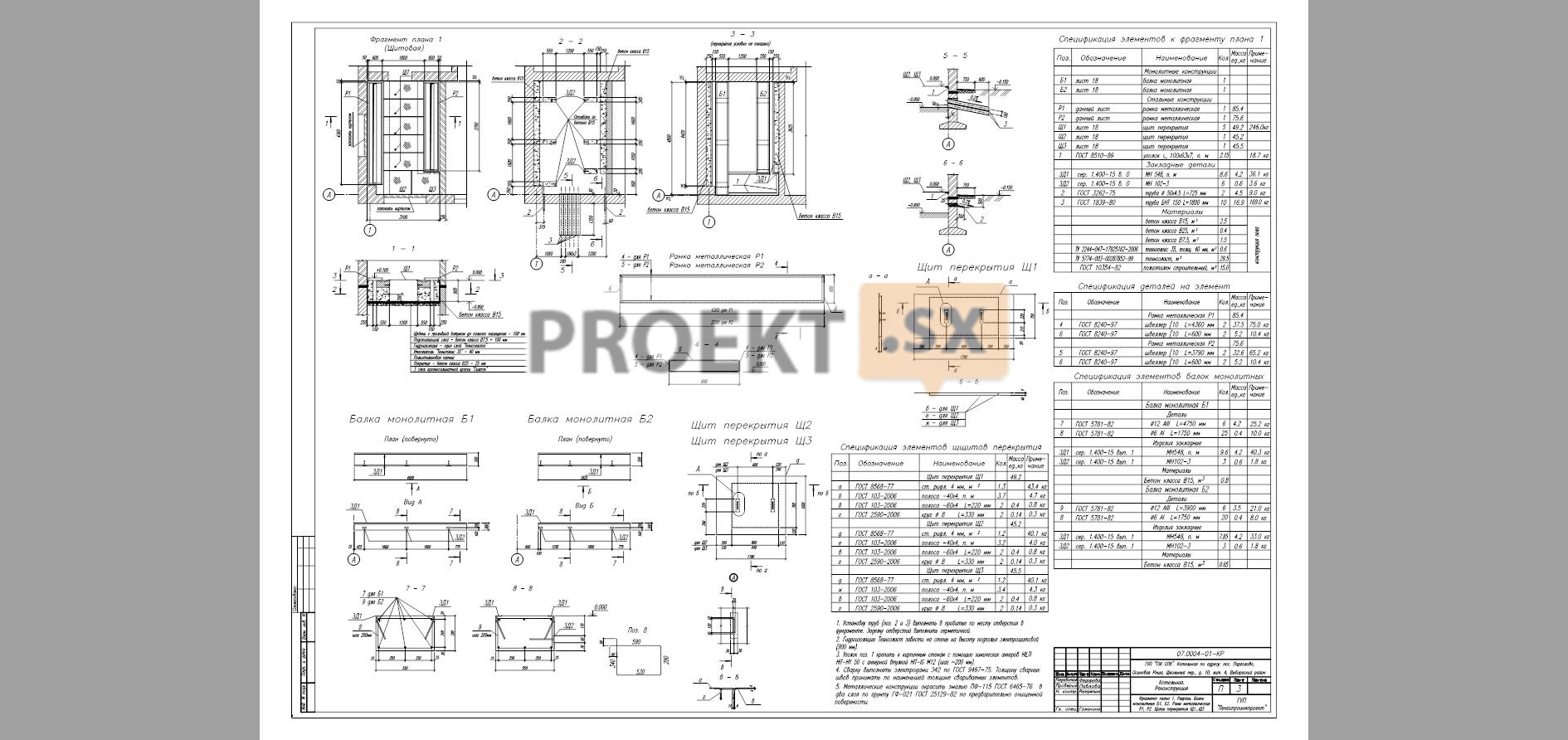

In accordance with technical surveys, the existing building of the boiler house was built in the late 70s of the last century according to the wall structural scheme. External walls - ordinary clay brick with an outer face layer of silicate brick, 380 mm thick, with pilasters 380x380 mm, operational condition. Internal walls - clay brick, thickness 250, 380 mm, working condition. Ceilings - technological platform of hollow-core slabs according to series 1.241.1 KL3, operational condition. Roof load-bearing structures - prefabricated ribbed slabs 1,5x6,0 m in size on prefabricated reinforced concrete beams (construction, material, working condition). Foundations - strip prefabricated FBS blocks 500 mm thick on prefabricated reinforced concrete slabs 1200 mm wide, operational condition. The base of the foundations is silty sandy loam with φ=29, e=0,431, E=140 kg/cm2. Engineering-geological surveys, on the basis of which the characteristics of soils are accepted. The bearing capacity of foundations, brick walls, floor and roof structures is sufficient to withstand design loads, the structures do not require reinforcement. The project provides for the dismantling of equipment with foundations, the dismantling of chimneys, the dismantling of the structure of the extension of the storage tank room. The project provides for the installation of new foundations for equipment, the installation of openings, the installation of a brick wall on a new foundation, the installation of metal platforms for maintenance. Wall - brick, M100 on the CPR M 50, foundation concrete B15, reinforcement AIII. The new structures were designed on the basis of manual calculations using the SNiP formulas. Additional settlement of the building after the reconstruction is not expected, since the load is less than it was before the reconstruction. Building renovation impacts, incl. from the construction of chimneys, on the surrounding buildings is not expected. The base for storage tanks is a monolithic reinforced concrete slab 300 mm thick. Foundation concrete B15, reinforcement AIII. Concrete preparation with a thickness of 100 mm, the existing soil is replaced with medium-sized sand to the freezing depth. Two chimneys 35 m and 20 m high, 1800 mm and 800 mm in diameter, free-standing, installed on their own foundation. Chimneys in the constructive section were not considered. The foundations of the chimneys are monolithic reinforced concrete on a natural base. Concrete B15, W4, F100. Class AIII fittings. The basis of the foundation is the EGE-2 soil: silty sandy loam with φ=29, e=0,431, E=140 kg/cm2. The design resistance of the base soil is not less than R = 3,2 kg / cm2. The average ground pressure is not more than 0,55 kg/cm2. The maximum groundwater level is near the daylight surface. Groundwater is not aggressive to concrete of normal permeability. In order to protect the concrete of underground structures, the surface of the concrete is protected by coating with hot bitumen for 2 times. Additional settlement of the reconstructed building is not expected, loads as a result of reconstruction do not increase. The stability of the pipes is ensured.