Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Cylinder filling station

Project documentation without estimates and the results of engineering surveys for the construction and reconstruction of the facilities of the station for filling cylinders with technical gases

Technical and economic characteristics of the capital construction object

Plot area, ha: 2,7332

Industrial building

Building area, m2: 925,22

Total area, m2: 828,66

Construction volume, m3: 7262,98

Floors, floor: 1

Administrative building

Building area, m2: 461,55

Total area, m2: 723,38

Construction volume, m3: 3666,90

Floors, floor: 2

Boiler room

Building area, m2: 45,9

Total area, m2: 35,22

Construction volume, m3: 123,27

Floors, floor: 1

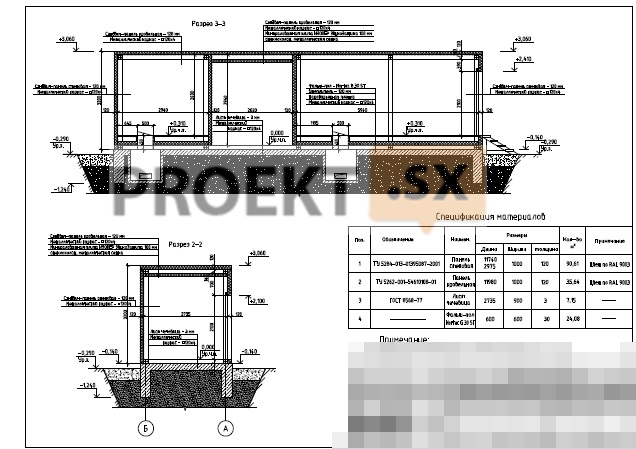

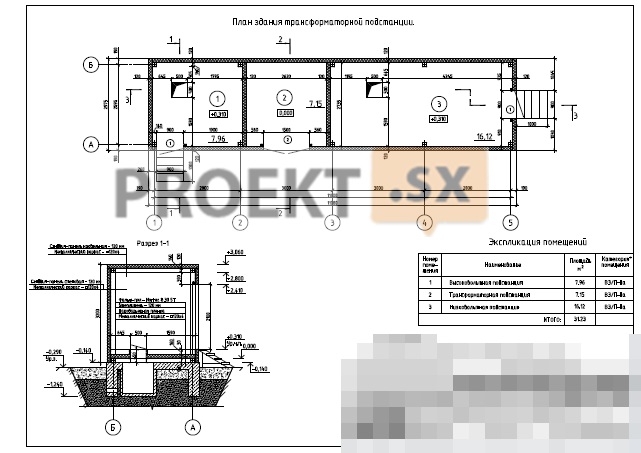

Transformer substation

Building area, m2: 37,44

Total area, m2: 31,23

Construction volume, m3: 119,40

Floors, floor: 1

Architectural and space-planning solutions

The design documentation provides for the reconstruction of an unfinished construction site for an industrial building and the construction of buildings for an administrative and amenity building (ABC), a boiler house, and a modular transformer substation.

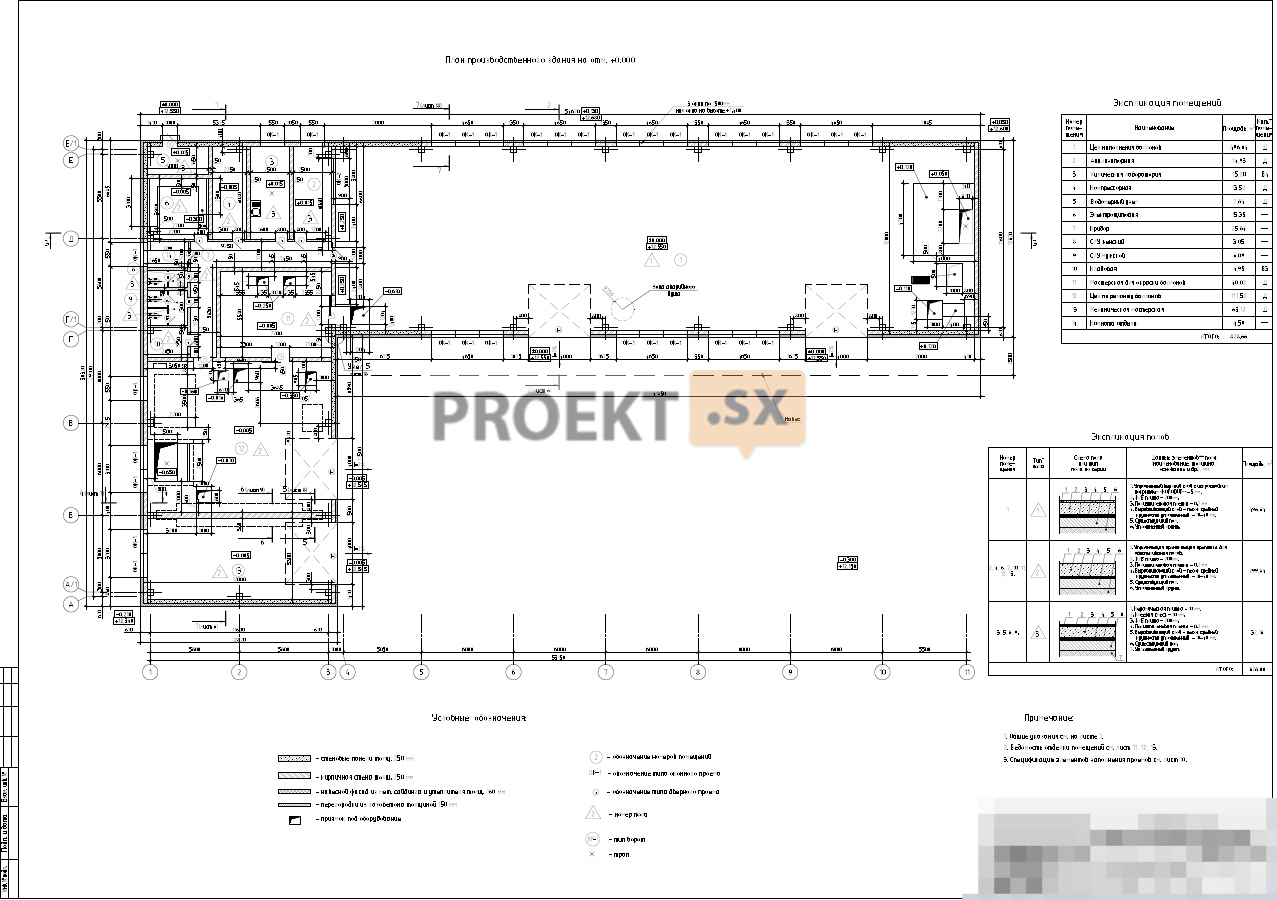

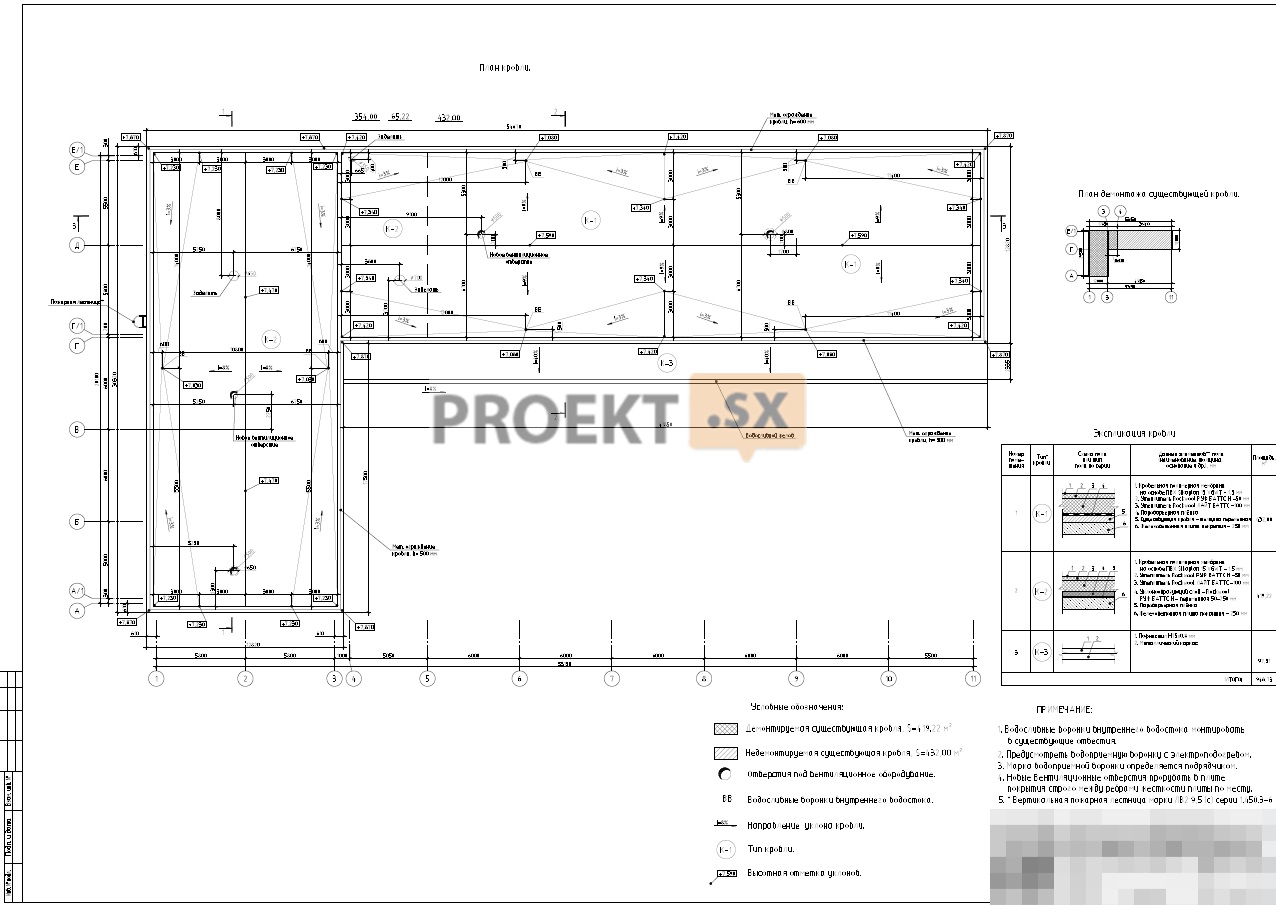

Industrial building. The object of construction in progress is a U-shaped 1,3-storey frame building in plan, consisting of three parts. The outer walls are made of hinged single-layer wall panels of expanded clay concrete, the inner walls and partitions are made of bricks, the ceilings are made of reinforced concrete hollow-core slabs, the roof is made of prefabricated reinforced concrete ribbed slabs, the roof is rolled. The project documentation provides for the reconstruction of the building with the dismantling of the 3-storey part. The designed building of the production building is L-shaped in plan, 1-storey, without a basement, with dimensions in the extreme axes of 53,150x29,100 m. The main entrance to the building is provided from the inside. For the relative mark of 0,000, the level of the finished floor of the building of the production building, corresponding to the absolute mark of 12.55, is taken. The maximum height of the building from the planning ground level to the parapet level (after reconstruction) is 8,035 m. The design documentation provides for: dismantling of the 3-storey part of the building; partial dismantling and repair of the roof with the installation of ventilation holes and drains; installation of a new concrete floor; construction of the inner wall and the outer end wall of brick; installation of a hinged facade; visor device; replacement of all window fillings; redevelopment of premises with the device of built-in premises, new internal walls, ceilings, partitions, door and window openings. At the level of 0,000, the following are planned: a cylinder filling shop, a cylinder repair shop, a mechanical workshop, a staff room, bathrooms, a storage room for cleaning equipment; in the built-in premises - an analysis room, a chemical laboratory, a compressor room, a water meter unit, an electrical panel room, a workshop for painting cylinders. The height of the built-in premises is 3,87, in the area of workshops and the workshop - 5,76 m to the bottom of the roof beams. The building has three emergency exits. Access to the roof is provided by an external staircase type P1. Exterior walls - hinged facade made of profiled sheet with mineral wool insulation on the existing wall panels. Covering - existing reinforced concrete ribbed slabs with mineral wool insulation. The roof is made of rolled materials with a protective layer of gravel, the drain is internal. The inner walls are brick. Partitions - from aerated concrete. Window fillings - two-chamber double-glazed windows in frames made of metal-plastic profile. The design documentation provides for interior decoration in accordance with the functional purpose of the premises.

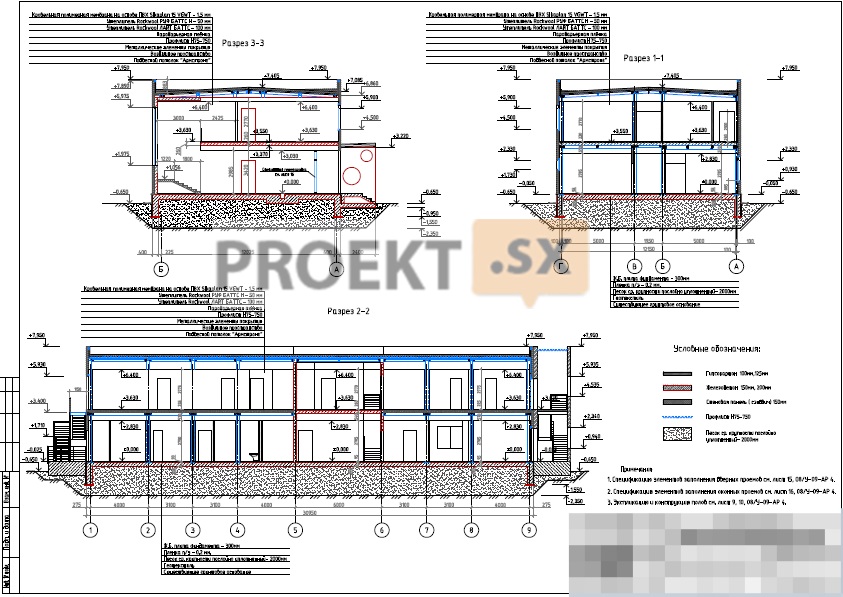

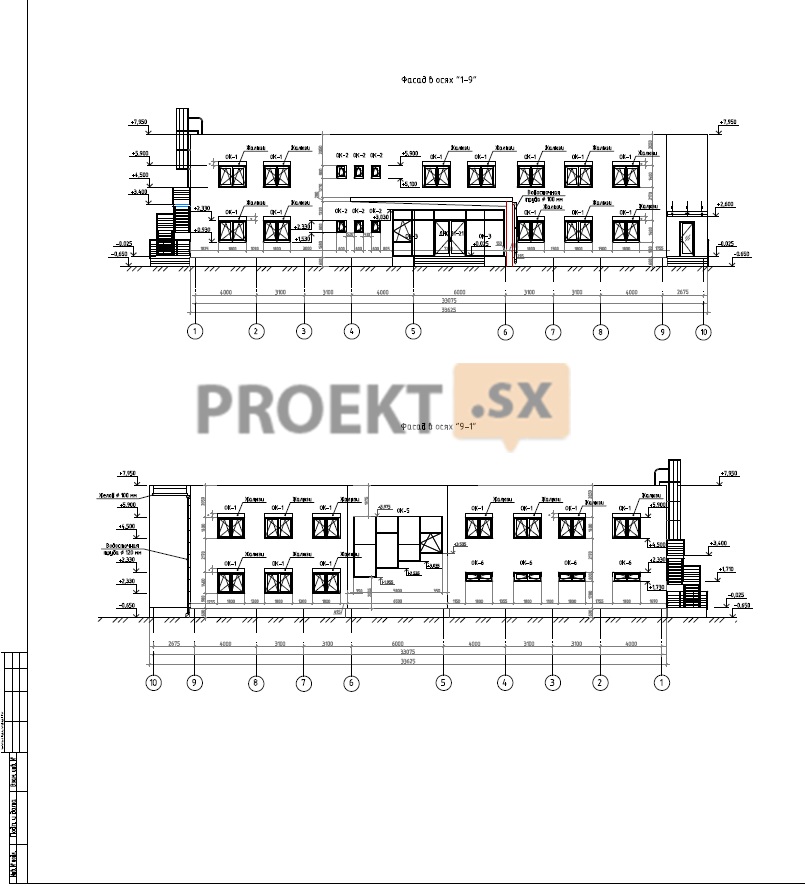

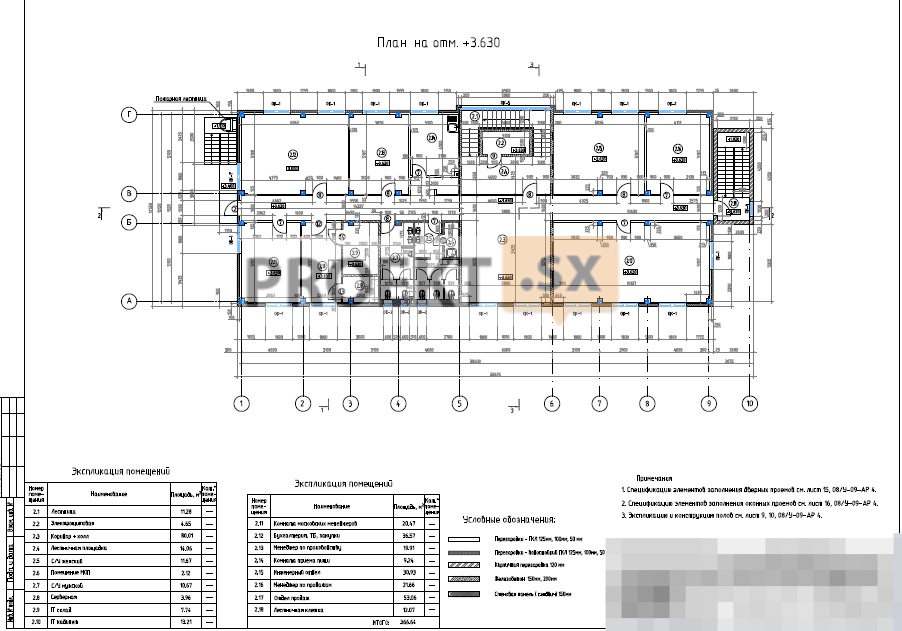

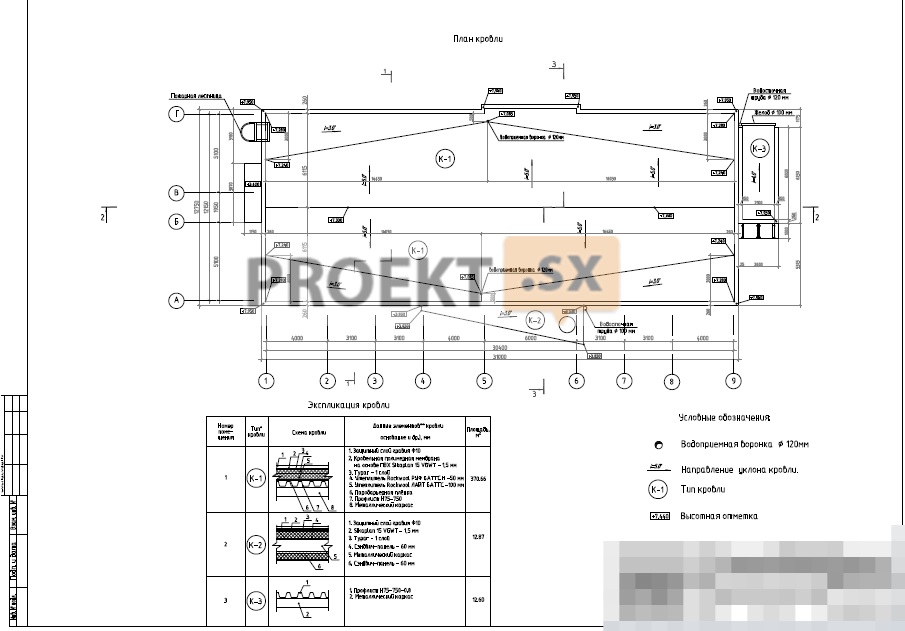

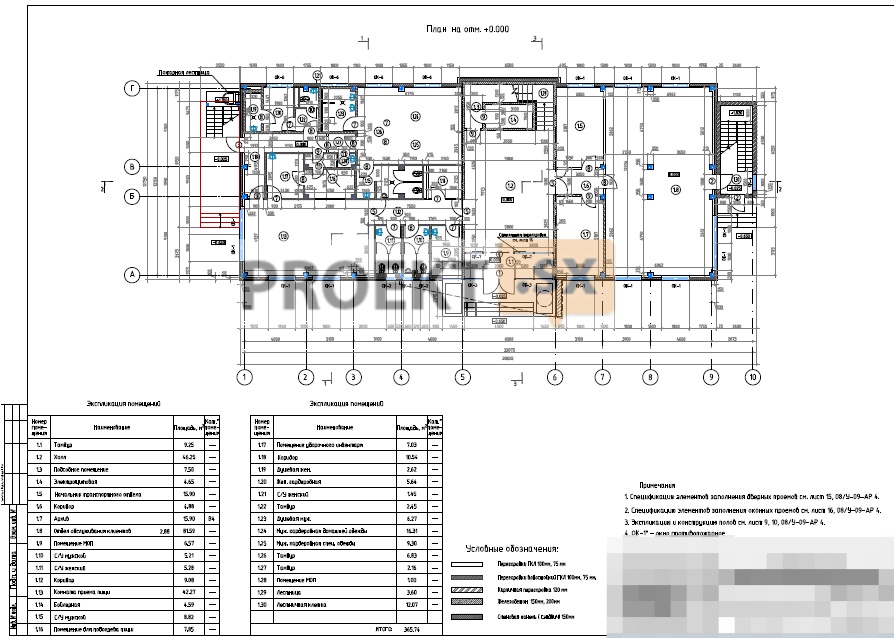

Administrative building. The designed building of the administrative building is a detached, rectangular in plan, 2-storey, without a basement, with dimensions in the extreme axes of 12,150x33,075 m. The main entrance to the building is provided from the internal territory. For the relative mark of 0,000, the level of the finished floor of the first floor of the building, corresponding to the absolute mark of 13.18, is taken. The maximum height of the building from the planning ground level to the top of the parapet is 8,6 m. On the ground floor, at the 0,000 mark, the following are designed: a lobby, an administrative room, an archive, a customer service room, a dining room, dressing rooms with showers, bathrooms, utility rooms, rooms for storing cleaning equipment, and technical rooms. On the second floor at the elevation of +3,630 m, the following are planned: administrative premises, a server room, a dining room, bathrooms, a storage room for cleaning equipment, and an electrical panel room. The height of the premises of the first floor is 2,83 m, the second - 3,77 m. For vertical communication in the building, one internal staircase is designed. For evacuation at the ends of the building, the following are designed: an attached staircase of type L1 and an external metal staircase of the third type. Access to the roof is provided by an external staircase type P1. The outer walls are made of sandwich panels. The covering is flat, made of profiled sheet with mineral wool insulation. The roof is made of rolled materials with a protective layer of gravel, the drain is internal. The internal walls are made of brick and reinforced concrete. Partitions - from aerated concrete and plasterboard on a metal frame filled with mineral wool slabs. Window fillings - two-chamber double-glazed windows in frames made of metal-plastic profile. The design documentation provides for interior decoration in accordance with the functional purpose of the premises.

Boiler building. The designed boiler house building is a one-story modular building, rectangular in plan, with dimensions in the extreme axes of 3,80 x 9,40 m. For the relative mark of 0,000, the level of the clean floor of the boiler room is taken, corresponding to the absolute mark of 12.87. The maximum height of the building from the planning ground level to the parapet level is 4,0 m. At the level of 0,000, it is planned: a diesel generator room and a boiler room. The outer walls are made of sandwich panels. The covering is flat sandwich panels. Drainage - external unorganized. Partitions - made of profiled steel sheet with plasterboard lining. Easily dropped structures are provided - part of the wall enclosing structure. The chimney is designed with a height of 10,4 m from the planned ground level.

Transformer substation. The designed building of the transformer substation is a stand-alone modular rectangular in plan 1-storey building with dimensions in the extreme axes of 2,6x11,6 m. For the relative mark of 0,000, the mark of the finished floor of the transformer substation was taken, which corresponds to the absolute mark of 12.50. The maximum height of the building from the planning ground level to the flat roof is 3,35 m. At the level of 0,000, a transformer substation is designed, at the level of +0,310 - a high-voltage substation and a low-voltage substation. The outer walls are made of sandwich panels. Covering - from roofing sandwich panels, drainage - external unorganized. Internal walls are made of sandwich panels. Sheds. The designed canopy for storing cylinders is a separate structure, rectangular in plan, with dimensions in the extreme axes of 22,0x43,6 m. The maximum height from the planning mark of the ground to the ridge of the canopy is 6,624 m. Covering - profiled flooring. The drain is external, unorganized. The fence is mesh. The internal walls are made of bricks. Canopy for pumps - a product of full factory readiness, supplied with the pumps.

Structural and space-planning solutions

The project documentation provides for the reconstruction of the existing building - an object of construction in progress with a readiness of 99% since 1990. Inspection of building structures of the building was carried out by specialists of ZAO Erkon in 2009. The building consists of a one-story production building, consisting of a cylinder inspection shop and a cylinder filling shop, and a three-story administrative building. The building is divided by expansion joints into three blocks. The project documentation provides for the dismantling of structures of the administrative building. The main load-bearing structures of the production building are prefabricated reinforced concrete columns and gable roof truss beams with a span of 12 meters. Covering - prefabricated reinforced concrete ribbed floor slabs. External walls - prefabricated expanded clay concrete single-layer panels 250 mm thick and brickwork 250 mm thick. The condition of the columns, slabs and roof truss beams is operational, with the exception of the roof beams in axes 7-10/G-E, which are in a limited operational condition. The condition of the wall fencing is limited operability. There is no pavement around the perimeter of the building. Spatial rigidity and stability of workshop frames is ensured by rigid coupling of columns with the foundation and the hard disk of the roof. In accordance with the verification calculations, the bearing capacity of the frame elements meets the requirements of building codes for strength and deformability. Foundations - monolithic reinforced concrete free-standing glass type. Foundations are in good condition. In accordance with the results of verification calculations, the average pressure along the base of the foundations does not exceed the calculated resistance of the foundation soil, taking into account the designed loads. Foundation reinforcement is not required. A relative elevation of 0,000 corresponds to an absolute elevation 12,50. The design documentation provides for: restoration of the protective layer of concrete in the structure of the roof truss beam, which is in a limited working condition; erection of a self-supporting brick wall with a thickness of 380 mm along the axis “E” in / about “1-3” and an end external self-supporting wall with a thickness of 250 mm along the axis “11” in / about “Г-Е”. Foundations for the walls - tape, from monolithic reinforced concrete B25; W4; F100; under the foundations, concrete preparation is provided with a thickness of 100 mm on crushed stone with a thickness of 100 mm and a sand cushion with a thickness of 150 mm; arrangement of a canopy with a reach of 2,5 m. The canopy is fixed to existing columns through anchor bolts; insulation of enclosing structures with a system with an air gap "VF MP" (TS No. 2944-10); installation of a monolithic reinforced concrete floor slab 200 mm thick on top of the existing base with the installation of technological pits, concrete B25; F100; W6; replacement of roofing is provided; pavement restoration. The project documentation provides for the installation of built-in premises in the axes “1-3 / D-E”. The covering of the built-in premises is in the form of a monolithic reinforced concrete slab with a total thickness of 150 mm along a profiled sheet and metal beams resting on brick walls 250 mm thick. The ABK building was designed according to the frame structural scheme. Spatial rigidity and stability of the frame is ensured by the rigid connection of the columns with the foundation, the presence of rigidity diaphragms, hard disks of the floor and cover. The main load-bearing elements of the frame are steel columns and roof beams. Steel C245. Stiffness diaphragms - monolithic reinforced concrete walls 200 mm thick made of B20 concrete. Overlapping - monolithic reinforced concrete slabs on fixed formwork from corrugated board on steel beams and girders with a total thickness of 150 mm; in the middle span - in the form of a monolithic slab 180 mm thick; concrete B20. Covering - profiled flooring on steel girders. External walls - three-layer sandwich panels 150 mm thick. The internal staircase is monolithic reinforced concrete. The relative mark of 0,000 corresponds to the absolute mark of 13,18. The foundations are designed on a natural base in the form of a monolithic shallow reinforced concrete slab 300 mm thick with a rib along the contour of the slab. The foundation is made of B25 class concrete; F100; W6. Under the foundation, a sand cushion with layer-by-layer compaction 2 m thick is provided. The estimated settlement of the foundation is 2,9 mm. The external attached staircase in axes 9-10 is designed in brick walls with a thickness of 250 mm; coating - profiled flooring on steel girders; stairs - from prefabricated reinforced concrete steps and monolithic reinforced concrete platforms along steel stringers and beams. The foundation is strip, made of monolithic reinforced concrete (B25; F100; W6), united on top with a slab. The external staircase along axis 1 from the +0,010 mark is designed in steel structures supported by the porch structures. The porch is designed in monolithic reinforced concrete. The canopy for storage of cylinders is designed in a steel tie frame. The frame columns and roof beams are made of rolled I-beams. Steel C245. Covering - profiled flooring on steel girders. Spatial rigidity and stability of the frame is ensured by the rigid connection of the columns with the foundation, the presence of vertical steel ties, and the hard disk of the cover. The rigidity of the pavement disk is provided by a system of horizontal ties in the pavement level. Fire wall and internal partition - masonry from solid brick M75; F100 380 mm thick on M50 mortar. The relative mark of 0,000 corresponds to the absolute mark of 12.25. Foundations - on a natural base of monolithic reinforced concrete (B25; F50; W6), columnar, free-standing (under the frame columns) and strip (under brick walls). Under the foundations, a concrete preparation device is provided. The canopy for pumps is designed in a steel tie frame. Frame racks - from box-section elements; covering beams - from rolled channels. Steel C245. Covering - profiled flooring on steel girders. Spatial rigidity and stability of the frame is ensured by the rigid connection of the columns with the foundation, the presence of vertical steel ties, and the hard disk of the cover. The rigidity of the pavement disk is provided by a system of horizontal ties in the pavement level. The relative mark of 0,000 corresponds to the absolute mark of 12.50. The foundation of the canopy for pumps - on a natural base of monolithic reinforced concrete (B25; F