Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

School project for 275 places

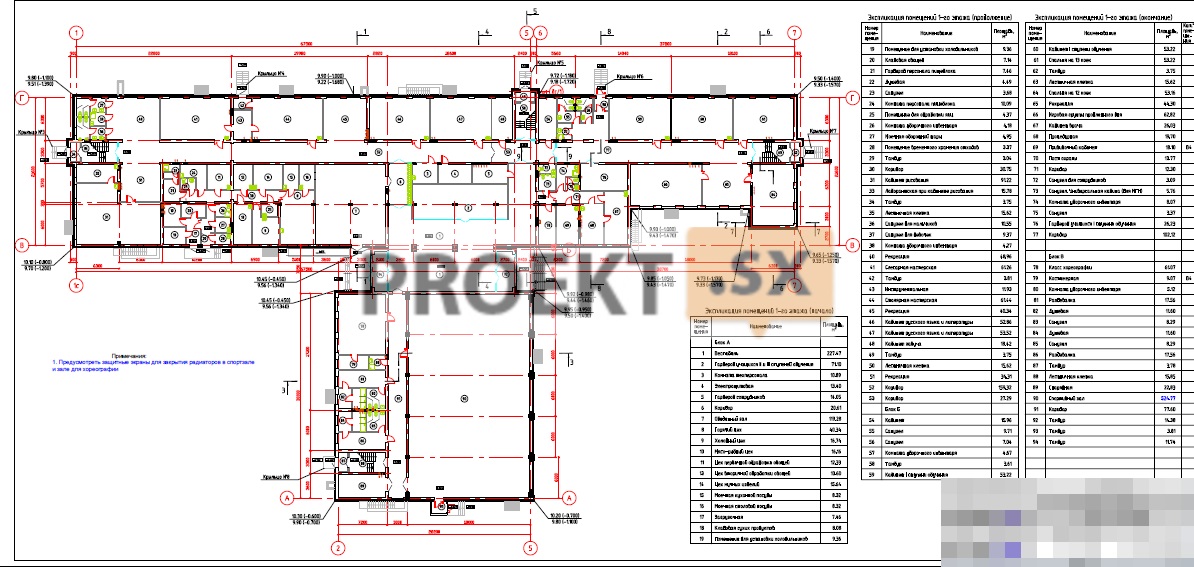

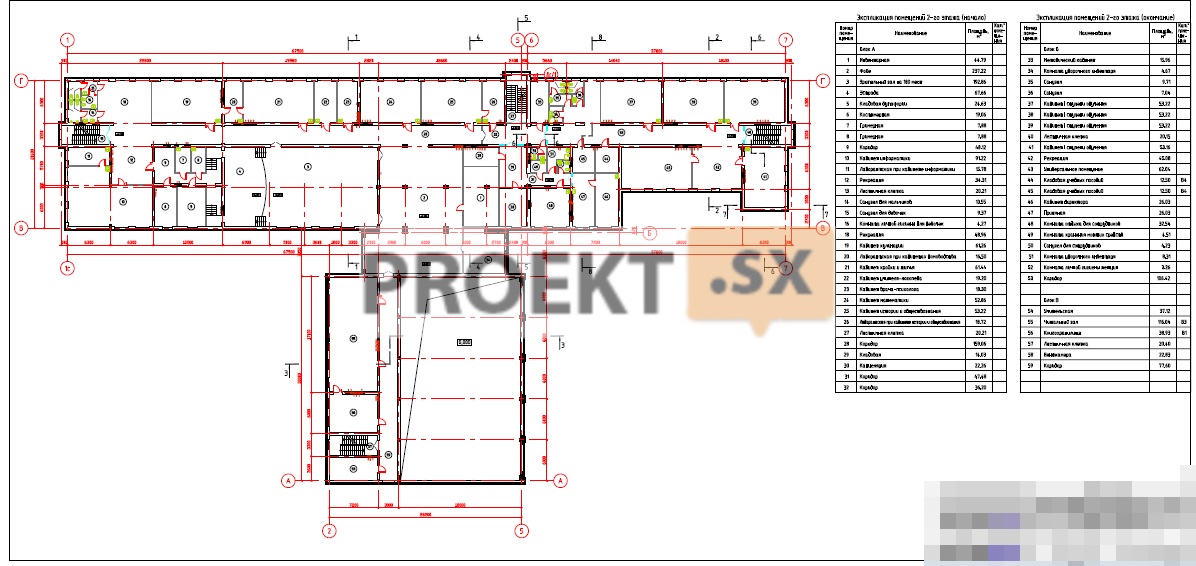

Technical and economic indicators:

Estimated area, m2: 5137,36

Usable area, m2: 6207,49

Total area, m2: 9293,69

Construction volume, m3: 44189,63

Including above-ground part, m3: 34585,64

underground part, m3: 9603,99

Building area, m2: 3491,21

Coating area, m2: 6339,0

Landscaping area, m2: 8013,0

Plot area, ha: 2,75

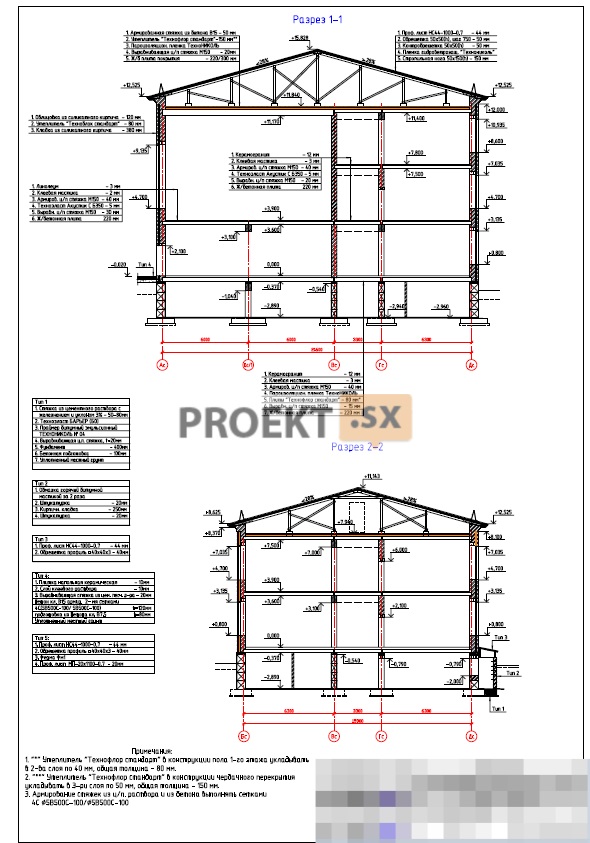

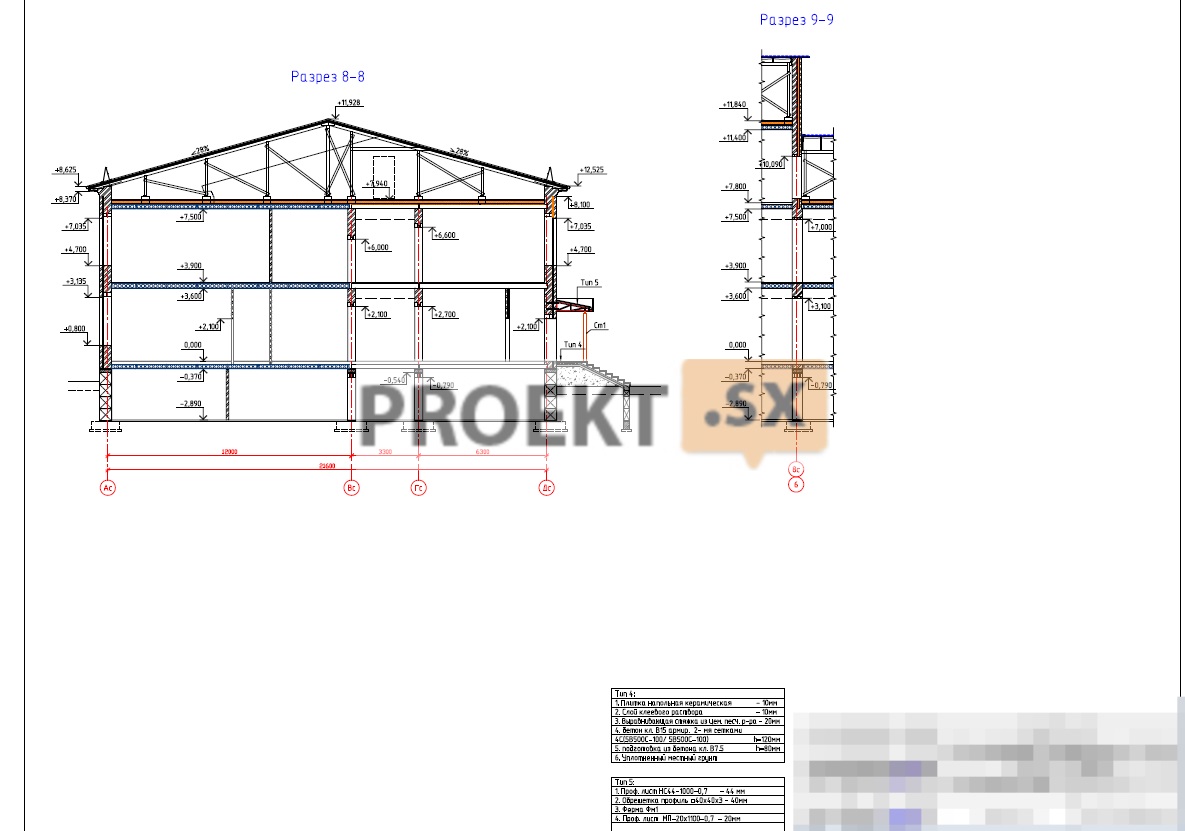

Number of floors, pcs.: 4-3 (including basement)

Duration of construction, incl. preparatory period, months: 12,5

Constructive decisions.

The designed building is brick, with a rigid structural scheme. The spatial rigidity of the building is ensured - in the horizontal plane by the operation of the floor slabs - as a horizontal stiffening diaphragm, in the vertical plane - by the operation of the longitudinal and transverse walls. The joint operation of each floor slab as a horizontal stiffening diaphragm is ensured by sealing the joints between the slabs with mortar and anchoring with the walls of the building. Bearing brick longitudinal and transverse walls are taken as the main load-bearing structures of the building. The foundations are designed according to the calculation, based on the geological conditions of the construction site and the collected loads. The foundation is a monolithic w/concrete tape made of concrete class. В25W6F50 on Portland cement according to GOST 10178-85 with content in clinker: С3S<=65%, С3А<=7%, С3А+С4AF<=22%. Under the sole of the grillage, a concrete preparation device 100 mm thick made of B7,5 concrete is provided with a launch to the sides by 100 mm. Basement walls to elev. -0.540 to mount from concrete blocks. Lay concrete wall blocks on M100 cement mortar with careful filling of vertical joints (dowels) with B15W6F50 class concrete with dressing of at least 1/2 of the block height. Separate sections between concrete blocks should be made of B15W6F50 concrete. In the corners and at the intersections of the basement walls, install reinforcing meshes made of wire ∅4V500C with a cell of 100x100, the meshes should go 1000 mm in each direction. Along the perimeter of all external and internal walls of the foundation at el. -0,540, a reinforcing belt is laid from rods ∅12 A500C interconnected by clamps ∅6A240 with a step of 300 mm. Perform horizontal waterproofing along the perimeter of all external and internal walls: at elev. - 0,540 from two layers of isol on bituminous mastic; at el. -2,940 and -0.390 from a cement mortar with a composition of 1: 2 with a thickness of 20 mm. Vertical waterproofing - coat all structures in contact with the ground with hot bituminous mastic for 2 times. Internal finishing of operated premises - lime painting on simple plaster. Exterior finish of the plinth - plaster, followed by painting with facade paints. The outer walls of the building above el. 0.000 perform: - silicate face brick SULPu-M150/F35/1,4 according to GOST 379-2015 (thickness 120mm - cladding); - ceramic brick KR-r-according to 1NF / 200 / 2,0 / 25 in accordance with GOST 530-2012 (thickness 380/510 mm - pillars). - ordinary silicate brick SURP-M150/F25/1,8 according to GOST 379-2015 (thick. 380mm - walls) Masonry should be carried out on a cement-sand mortar M100. - To plaster the outer walls from the inside with porous gypsum-perlite plaster in accordance with GOST 28013-98 * with a density of 500 kg / m3, a thickness of 20 mm. Perform multi-layer masonry according to ser. 2.030-2.01 with horizontal stiffening diaphragms with a step of no more than 500 mm in height. Internal load-bearing walls should be made of ceramic brick KURPO 1.4NF/150/2.0/25 according to GOST 530-2012 on cement-sand mortar M100. Partitions should be made of ordinary silicate brick SURP-M150/F25/1,8 according to GOST 379-2015 on cement-sand mortar M100. Reinforcement of wall sections with ventilation ducts is performed with meshes of reinforcement ∅4V500C with a cell of 50x50 through 4 rows of masonry in height. Ceilings - prefabricated reinforced concrete slabs, ser. 1.141-1 вып.60,63,64; ГОСТ 9561-91; ТУ-5842-001-01217316-15, ИИ03-02. Lay the slabs on a layer of freshly laid cement-sand mortar M 100 up to 20 mm thick. The voids of the slabs in the places of leaning on the walls should be sealed with concrete of class B15. Seal depth not less than 250mm. Plates longer than 7,2 m should not be used with pinching on the supports. Lintels - prefabricated reinforced concrete according to GOST 948-2016. Lay the lintels over a layer of freshly laid cement-sand mortar M 100 20 mm thick. Lintels should be supported on solid brick KR-r-according to 1NF / 200 / 2,0 / 25 in accordance with GOST 530-2012. Reinforced lintels should be laid from the side where the floor slabs are supported. Window blocks - from polyvinylchloride profiles GOST 30674-99 with a two-chamber double-glazed window. Door blocks: external-steel according to GOST 31173-2003 and PVC profile according to GOST 30970-2014; internal doors - wooden according to GOST 475-2016, fireproof metal doors according to gray. 1.036.2-3.02 v.1; Floors - linoleum, porcelain stoneware, wood. Interior decoration of the premises - water-based painting on improved plaster with installation of aprons made of ceramic tiles around the washbasins to a height of 1,6 m; ceramic tiles on plaster for the entire height of the room. The roof is double-pitched on wooden rafters, with a walk-through attic.