Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

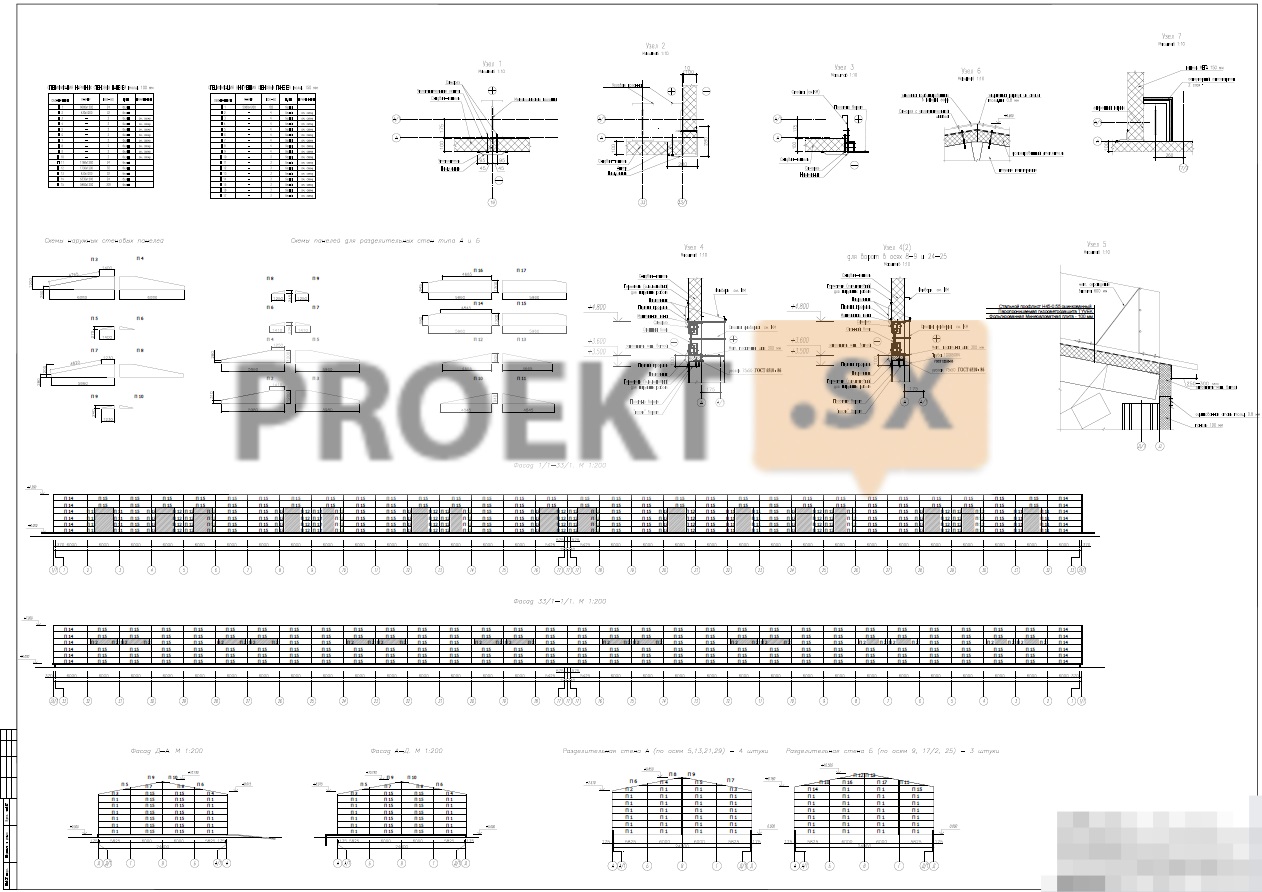

Grain container storage project

Technical and economic characteristics of the capital construction object

Plot area within the land allotment, ha: 1,7288

Plot area within the design boundaries, ha: 1,0884

Building area, m2: 5094,2

The total area of the grain storage warehouse building, m2: 4625,7

Construction volume of the grain storage warehouse building, m3: 40731,5

Floors, floor: 1

Architectural and space-planning solutions

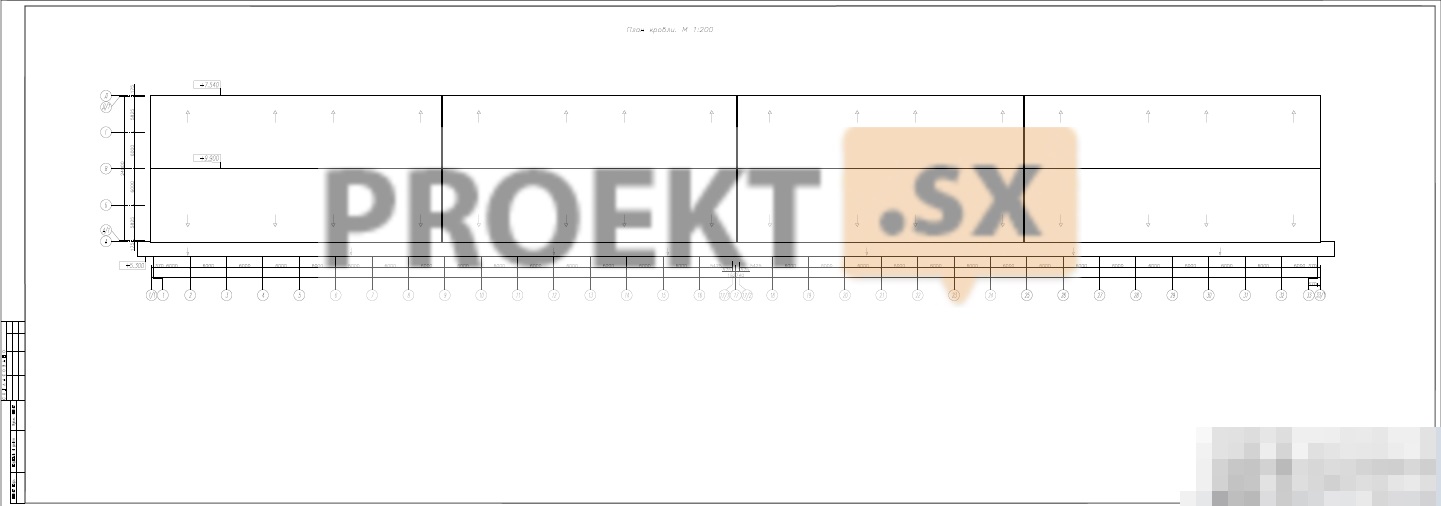

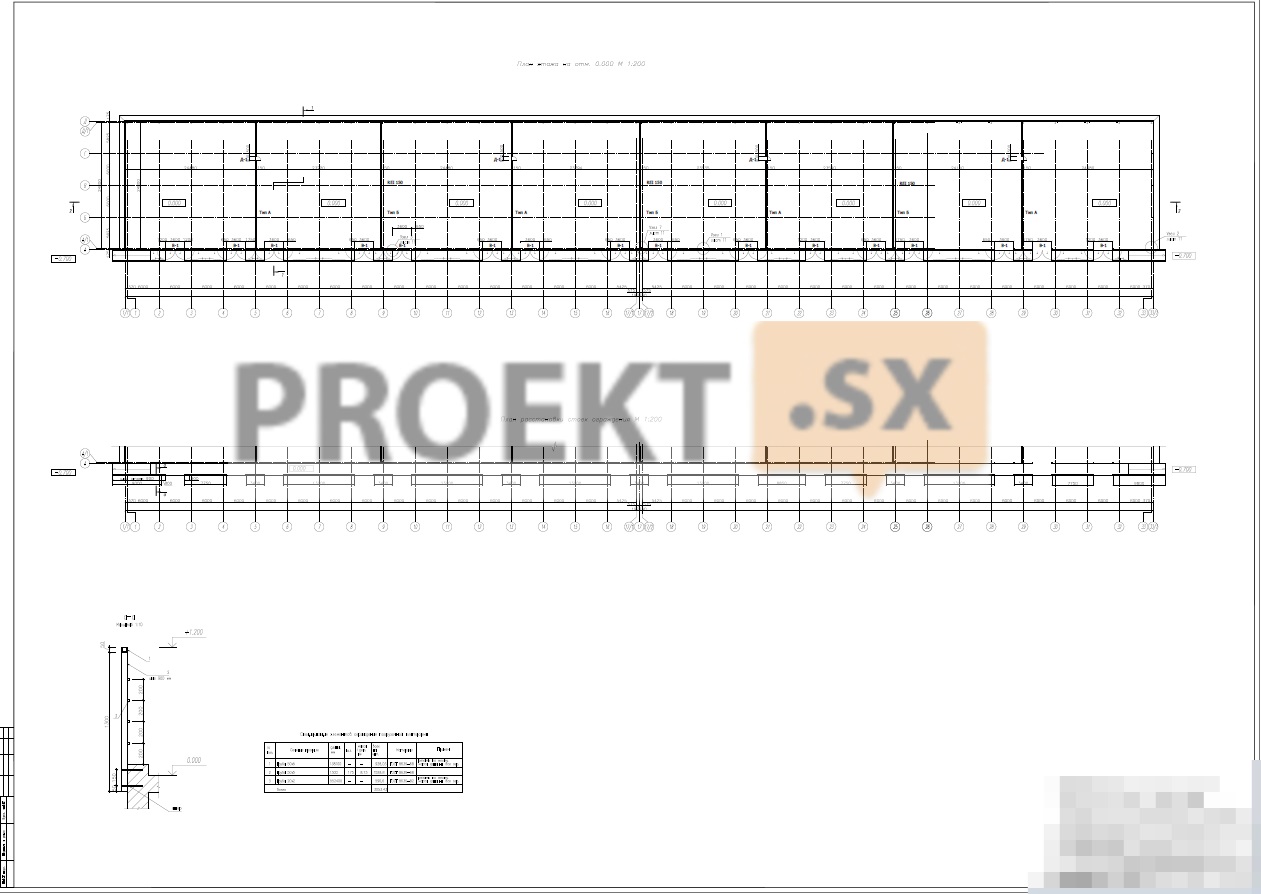

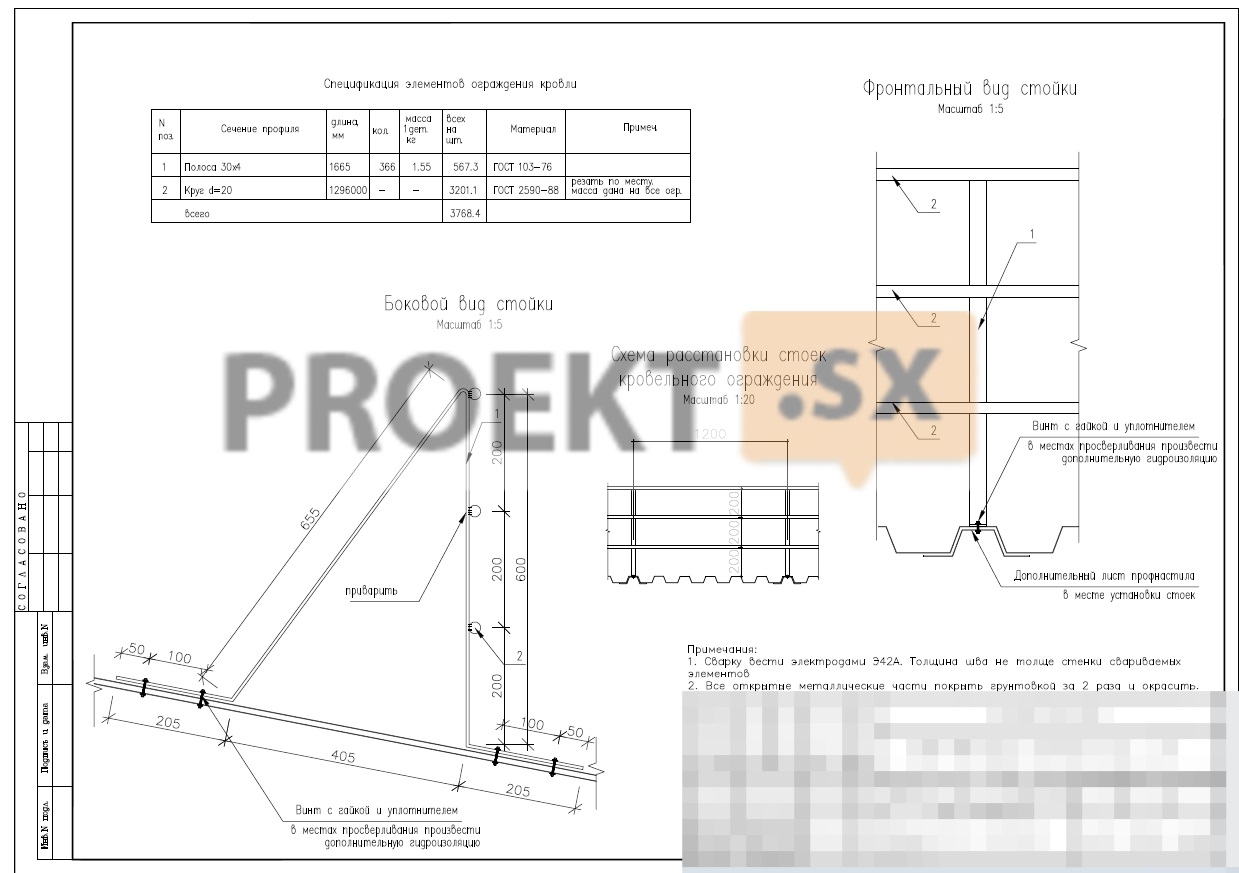

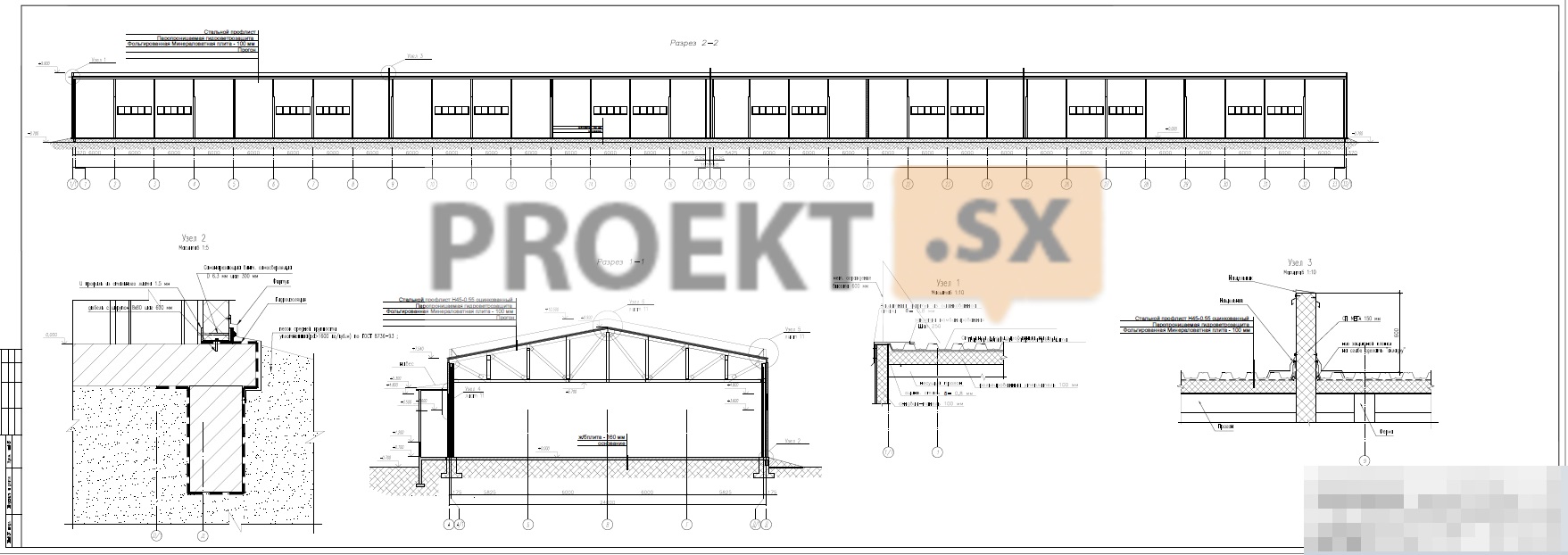

The warehouse for grain storage is designed on the territory owned by the customer. The warehouse is intended for long-term container storage of grain (rye, wheat) in bags (big bags with a capacity of 1000 kg) on pallets in stacks. The warehouse building is designed as a one-story building, without a basement, without heating, with dimensions in the plan of 24,0x192,0 m in the axes. The mark of the clean floor of the warehouse building is taken as 0,000. The height to the bottom of the protruding structures is 5,70 m. The maximum height of the building from the ground to the top of the roof ridge is 10,60 m. The warehouse building is divided into 4 fire compartments, each of which has two sections for container storage of grain in stacks. The outer fence of the warehouse is designed from sandwich panels 100 mm thick, the inner walls - from sandwich panels 150 mm thick. The roof is gable, made of steel profiled sheet, with an unorganized drain. A ramp (platform) with two ramps is provided for loading and unloading bags of grain along the entire front of the warehouse building (along axis A). frame heightpy 0,7 m, its top is designed on the same level with the floor of the warehouse. In accordance with clause 5.12 of SNiP 31-04-2001, a canopy 1,5 m wide is provided above the ramp. Each section of the warehouse has two swing gates (with a door in one of the panels) with access to the ramp. Each section also has single-glazed strip windows. The technology provides for the delivery of grain in bags (big-bags) by car to the ramp, then reloading onto the ramp with a forklift and then by electric stackers, delivery of the cargo to the warehouse and stacking. The warehouse building provides only premises for container storage of grain. All administrative, sanitary and technical premises are provided in the existing buildings. In accordance with the customer's letter, with this technological process in the container storage building, the design documentation does not provide for the use of disabled labor and the reception of visitors.

Structural and space-planning solutions

Building responsibility level - II. The building is divided by 3 sedimentary-deformation joints into 4 blocks. The building was designed according to the frame structural scheme. The columns are steel, designed from I-beams and bent-welded pipes made of C255 steel. The main column spacing is 24x6 m. Cover structures are designed from metal roof trusses with rigid interface with columns. Farms are designed from bent-welded profiles (pipes). Pipes - according to GOST 30245-2003. Steel C255. The outer walls are designed from hinged sandwich panels 100 mm thick. The internal walls are designed from hinged sandwich panels 150 mm thick. Spatial rigidity and overall stability of the building are ensured by the joint work of columns fixed in the foundations, horizontal and vertical connections. The calculation of load-bearing structures was carried out on a computer using the SCAD 11.1 program and manually using the SNiP formulas. The foundations are taken columnar on a natural basis. Concrete B20,W8, F200. It is planned to build a ramp supported by a retaining wall. The retaining wall is designed from monolithic reinforced concrete 200 mm thick. Concrete B20,W8, F200. A 100 mm thick concrete preparation is provided under the foundation. The calculation of the foundation is made manually according to the formulas of SNiP. The relative mark of 0,000 corresponds to the absolute mark of 21.80. In accordance with the report on engineering and geological surveys, coarse sand with E = 500 kgf / cm2 will serve as the basis for the foundations; c=0,02 kgf/cm2, e=0.45; f=43°. In order to protect the concrete of underground structures, the concrete grade for water resistance is W8, and the side surfaces are coated with bituminous mastic twice. The expected average settlement of the building is not more than -1,0 cm. In accordance with the technical conclusions made in 2011, the following fall into the risk zone: 2-storey administrative building, 11 meters from the designed warehouse; warehouse building 28 meters from the designed warehouse. All buildings belong to the 1st category of technical condition. The expected additional settlement of the surrounding buildings is less than the maximum allowable values.