Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

indoor sports complex

Project documentation without estimates and results of engineering surveys for the construction of an indoor sports complex without stands for spectators

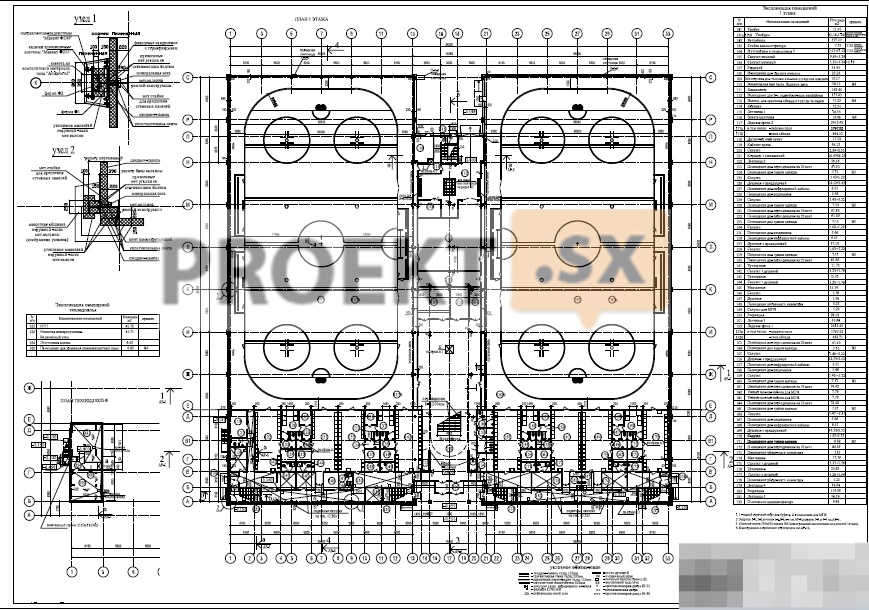

Technical and economic characteristics of the capital construction object

Sports complex

Plot area, ha: 2,0783

Built-up area of the building, m2: 7240,0

Total area, m2: 9490,0

Construction volume, m3: 78827,0

Floors, floor: 1-3

Boiler room

Built-up area of the building, m2: 61,1

Total area, m2: 58,9

Construction volume, m3: 186,3

Floors, floor: 1

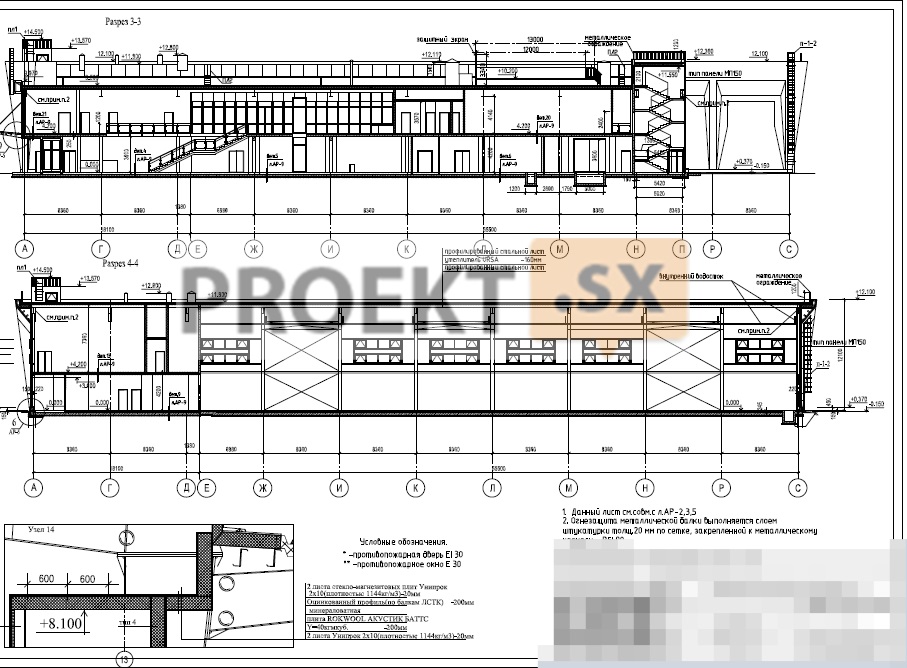

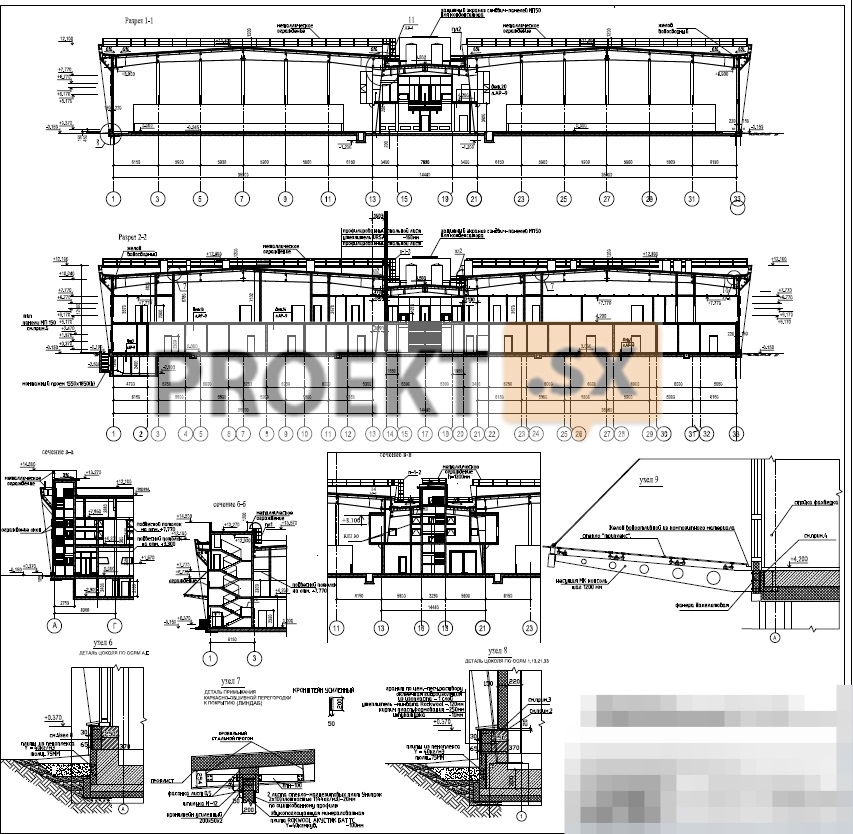

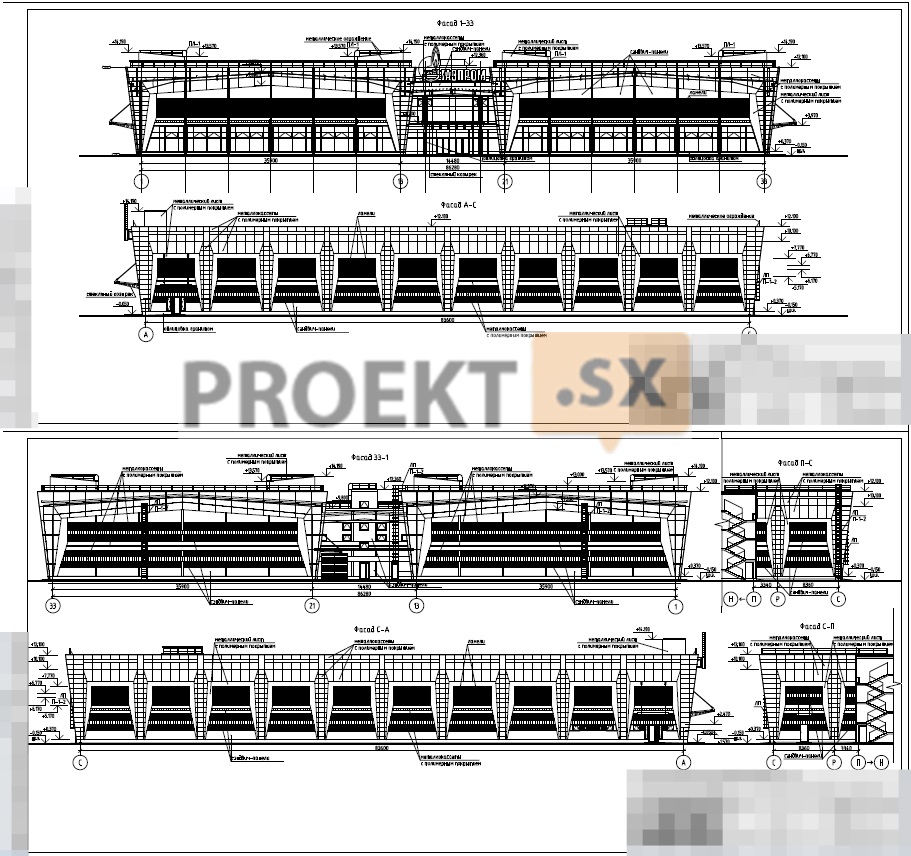

Architectural and space-planning solutions

The designed indoor sports complex without stands for spectators is a separate building, rectangular in plan, 1 - 3 floors, with dimensions in the extreme axes 86,28 x 83,60 m. The main entrance to the building is provided from Babushkina Street. For service personnel, the entrance is provided from the intra-quarter territory. The maximum height of the building from the planning mark of the ground to the top of the parapet is 12,25 m. The level of the finished floor of the first floor, corresponding to the absolute mark of 0,000, is taken as a relative mark of 6.25. The designed building consists of two main one-story volumes with ice arenas, separated in the center by a two-story insert with balconies, and a three-story insert at the end of the building. Under a part of the three-story insert at the level of -2,900 in the technical basement, technical rooms were designed: ITP, fire extinguishing pumping station and water metering unit, a room for storing fluorescent lamps. The height of the technical basement rooms is 2,4 m. On the ground floor at the 0,000 mark, the following are designed: two ice arenas, each measuring 61,0 x 30 m, an entrance group with a vestibule, a wardrobe for outerwear, a rental room and a workshop for sharpening skates, eight groups changing rooms, coaching, massage rooms, doctor's office, administrator's room, technical rooms, bathrooms, rooms for storing cleaning equipment. The height of the first floor is 4,20 m, the height of the premises of the ice arenas to the bottom of the protruding roof trusses is 8,90 m. On the second floor of the end insert at elevation +4,200, the following are designed: recreation, three halls - for choreography, for acrobatic training, a fitness room, inventory rooms, changing rooms, administrative rooms, a meeting room, rooms for staff, technical rooms, bathrooms, rooms for storing cleaning equipment . The height of the premises of the second floor of the inserts is 4,200 m, the technical premises of the central insert to the bottom of the protruding structures are 3,57 m, the technical premises of the end insert are variable - 4,14-4,6 m. On the third floor of the end insert at the level of +5,8 designed: two rooms for psychological relief. The height of the premises is 2,6 m. Five stairwells of the L1 type are designed for vertical communication between the floors, and an open staircase is designed for communication between the first and second floors in the lobby. Exits to the roof are provided from five stairwells and three external metal stairs. The outer walls are made of element-by-element sandwich panels. The plinth is made of solid brick, insulated with mineral wool boards and lined with natural stone. Covering - profiled steel sheets with insulation with mineral wool boards (sandwich panels of element-by-element assembly). The drain is internal. Internal walls and partitions - from solid brick, aerated concrete, gypsum plasterboard and gypsum plasterboard on a metal profile, LSU slabs. Interior decoration is carried out in accordance with the functional purpose of the premises. Filling window openings - metal-plastic blocks with double-glazed windows. Stained-glass windows made of aluminum profiles with double-glazed windows, in the premises of ice arenas - made of aluminum profiles with single-chamber double-glazed windows. The project documentation ensures the accessibility of the first and second floors of the complex for people with limited mobility: the entrance is provided from the ground level, for access to the second floor at the level of 0,000 a lift for the disabled with vertical movement is provided, bathrooms with a universal cabin are provided, a fireproof zone is designed. A gas boiler house was designed without the constant presence of service personnel - a separate, container type with a steel frame. The building is one-story, with dimensions in the extreme axes of 9,0 x 6,54 m. The height from the planning mark of the ground to the ridge is 3,45 m.

Structural and space-planning solutions

Building responsibility level – II. The building was designed according to the frame-braced design scheme. Columns - steel from a welded I-beam of variable section. The main pitch of the columns is 35,90x8,36 m and 14,48x8,36 m. Steel columns C345. Covering beams - steel from a welded I-beam of variable section. Beam steel C345. External walls - hinged sandwich panels 150 mm thick. Covering - sandwich panel (elemental assembly) 160 mm thick on metal girders, which are supported by metal frame structures. The light metal frame of Astron Buildings LLC (the assignee of Lindab Buildings) has a technical certificate from the Ministry of Regional Development. The presented project documentation received a positive conclusion. The building is provided with inserts designed according to a mixed structural scheme, separated from the ice arenas by expansion joints. Columns - monolithic reinforced concrete with a section of 300x300 mm. The main column spacing is 7,68x8,36 m, concrete B25. Pylons - monolithic reinforced concrete with a section of 1200x200 mm. Concrete B25. Internal walls - monolithic reinforced concrete 200 mm thick. Concrete B25. Floor slabs - monolithic reinforced concrete 200 and 250 mm thick. Floor slab concrete - B25. Partitions are designed brick 120 mm thick, aerated concrete 100 mm thick and frame-sheathed (gypsum board on a metal frame). Stairs are designed from monolithic reinforced concrete, B25 concrete. The spatial rigidity and stability of the building is ensured by the joint work of vertical ties, the rigidity of the frame joints of columns with beams and hard disks of floors. The calculation of load-bearing reinforced concrete structures was carried out on a computer using the Lira program (version 9.6), the calculation of metal structures was carried out using the Order Processing System program, taking into account possible uneven deformations. The foundations are designed as pile foundations. Bored piles with a diameter of 580 mm (performed to protect the casing pipe, length from 12,6 m to 15,8 m (absolute marks of the heel of piles -10.00) . Concrete B25,W6, F75. The design load on the pile is assumed to be 69 tf according to static sounding data. Forces in piles do not exceed 65 tf. Grills for the main frame columns are made of monolithic reinforced concrete, concrete class B30, W8, F75. The connection between piles and grillage is rigid. Grills for ice arenas and built-in slabs made of monolithic reinforced concrete, concrete class B30, W8, F75. The pairing of piles and grillage is articulated. A concrete preparation 100 mm thick is provided under the grillage. The calculation of the foundation was made on a computer according to the program according to the Lira program (version 9.6). The relative mark of 0,000 corresponds to the absolute mark of 6.25. In accordance with the report on engineering and geological surveys of IGL GeoProject LLC (reg. No. 1377/1) of 2012, the piles are based on light silty hard plastic loams with IL=0,42, φ=220, E=110 kg/cm2, light silty soft loams with IL=0,60, φ=210, E=100 kg/cm2, sandy loam with sand interlayers, hard with IL=-0,09, φ=270, Е=160 kg/cm2. The maximum groundwater level is near the daylight surface. Groundwater is non-aggressive to concrete of normal permeability. Boiler room. The modular boiler house is designed from easily assembled metal structures with sandwich panel cladding. Metal structures are made of a closed bent profile 140x100x6 and others (connections from a bent profile 80x4) according to GOST 30245-2003. External walls - hinged sandwich panels 100 mm thick. Covering - from a sandwich panels 100 mm thick on a metal frame. Spatial rigidity and stability of buildings is provided by vertical connections and rigid junctions of columns and crossbars. The foundations are taken in the form of a monolithic reinforced concrete slab 250 mm thick, concrete B20, W6, F50. Under the foundation, a concrete preparation 100 mm thick is provided on a sand cushion 2,75 m thick. The chimney (2 flue pipes) 9 m high and with an outer diameter of 500 mm are fixed on a spatial metal structure installed on its own foundation. The metal structures of the chimneys are made of racks (a pipe with a diameter of 89x5), united by a lattice of 70x6 corners. The foundations for the pipe are piled. Prefabricated reinforced concrete driven piles with a section of 350x350 mm, 9 m long (the absolute mark of the pile heel is -2.70). Pile driving is designed by the indentation method. Piles are designed according to series 1.011.1-10. The design load on the pile is assumed to be 15 tons according to static sounding data, the force in the piles does not exceed 4 tf. The grillage for the pipe is separate from monolithic reinforced concrete 400 mm thick, concrete class B25, W6, F50. The connection between piles and grillage is rigid. A 100 mm thick concrete preparation is provided under the foundation. Concrete B20, W6, F50. The relative mark of 0,000 corresponds to the absolute mark of 5.90. In accordance with the report on engineering and geological surveys, heavy silty fluid loams with φ=5, c=0,06 kg/cm2, E=30 kg/cm2 serve as the base of the sand cushion. The design resistance of the base soil (underlying layer) is not lower than R = 0,63 kg/cm2, the pressure on the base soil is not more than 0,21 kg/cm2. The piles are based on light, silty, refractory loams with IL=0,45, φ=18, c=0,24 kg/cm2, E=100 kg/cm2. In order to protect the concrete of underground structures, the concrete grade for water resistance is W6, the concrete surface is protected by coating with mastic. The expected average settlement of the building is not more than 20 mm. Pipe stability is guaranteed.