Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Project ADES 800 kW

Technical and economic indicators

Plot area, ha: 0,56

Plot area in the fence, ha: 0,56

Building area, ha: 0,0746

Building density, %: 13

Diesel fuel consumption, t: 240,5

Consumption of engine oil Cat DEO 10W30, t: 4,85

Architectural solutions

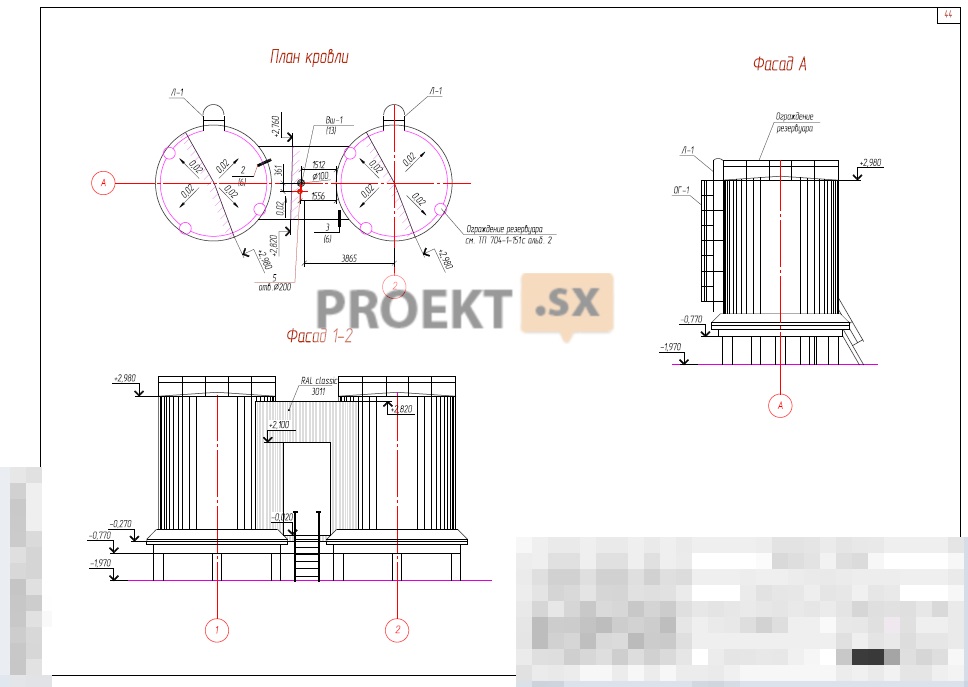

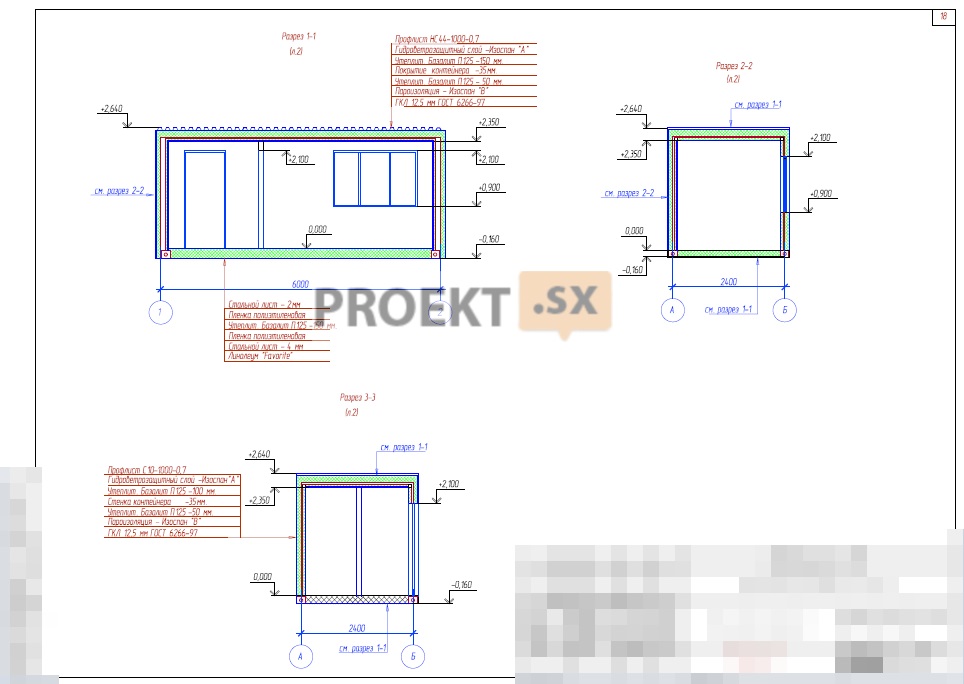

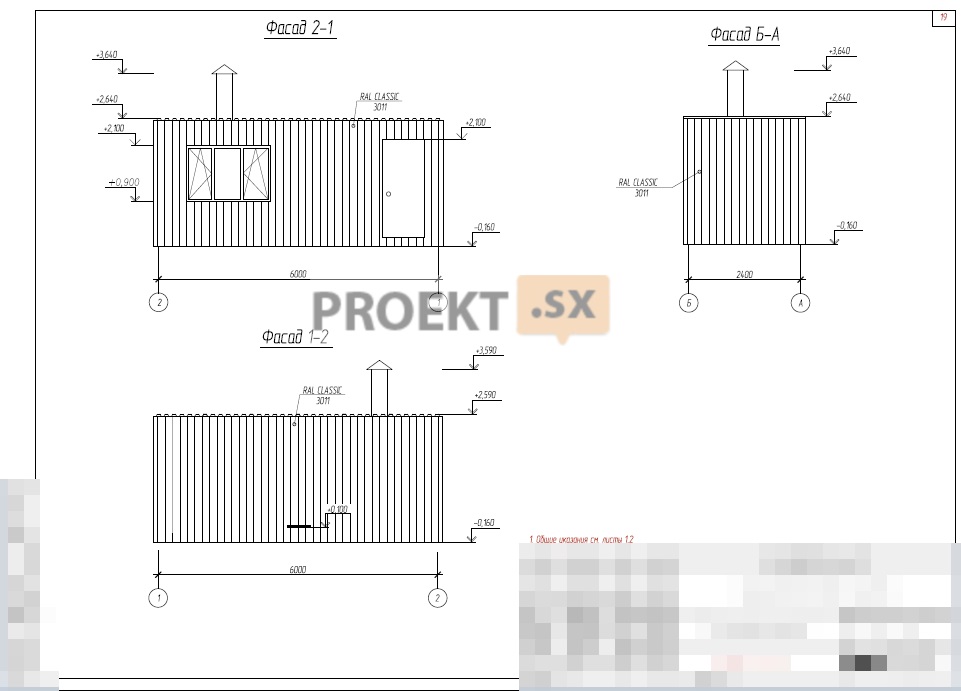

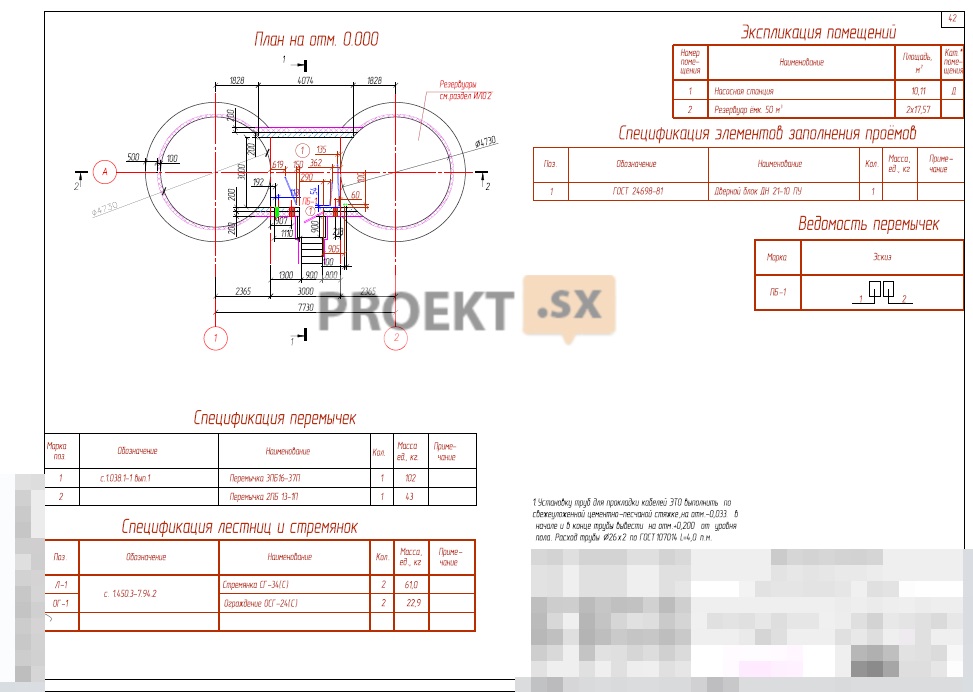

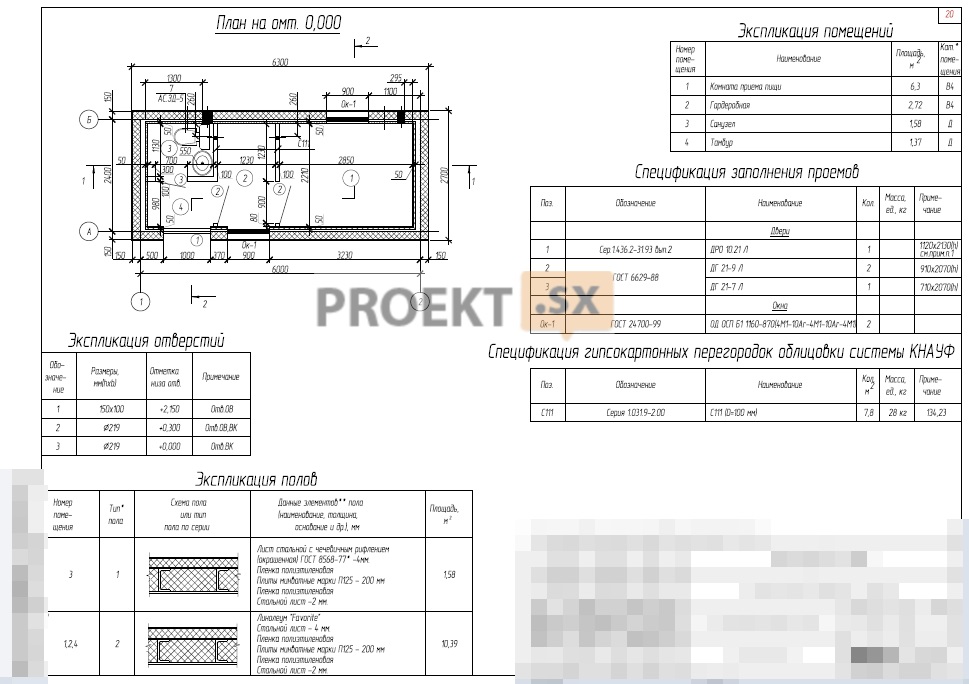

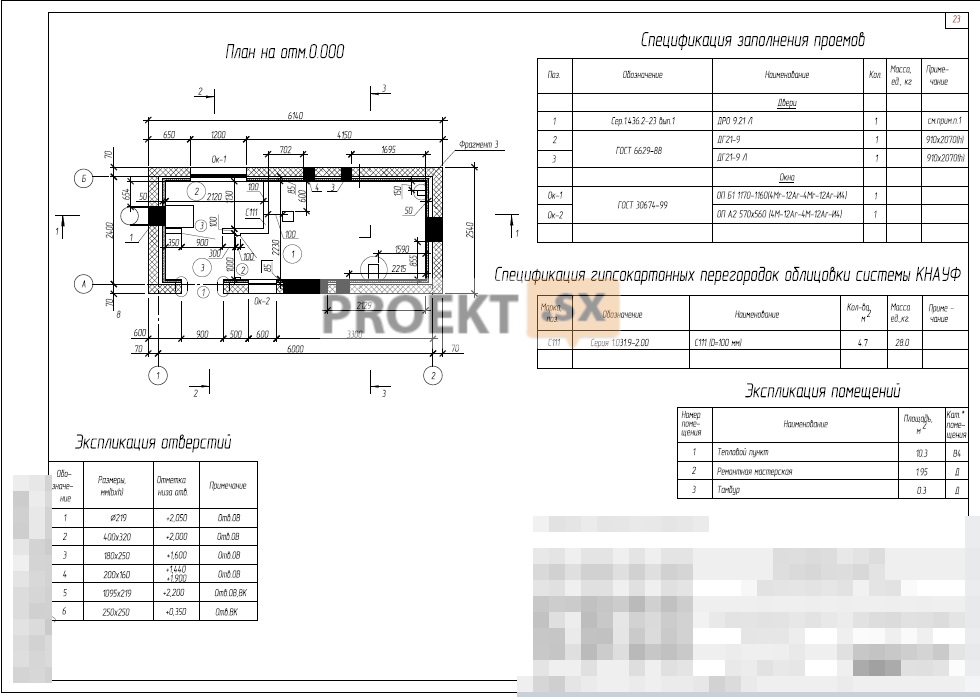

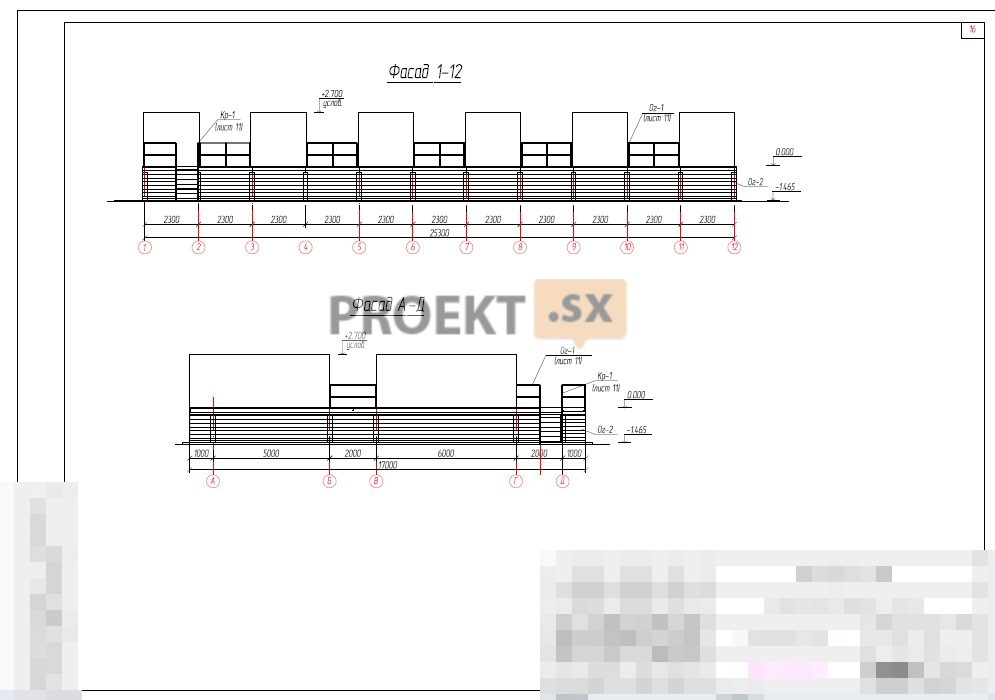

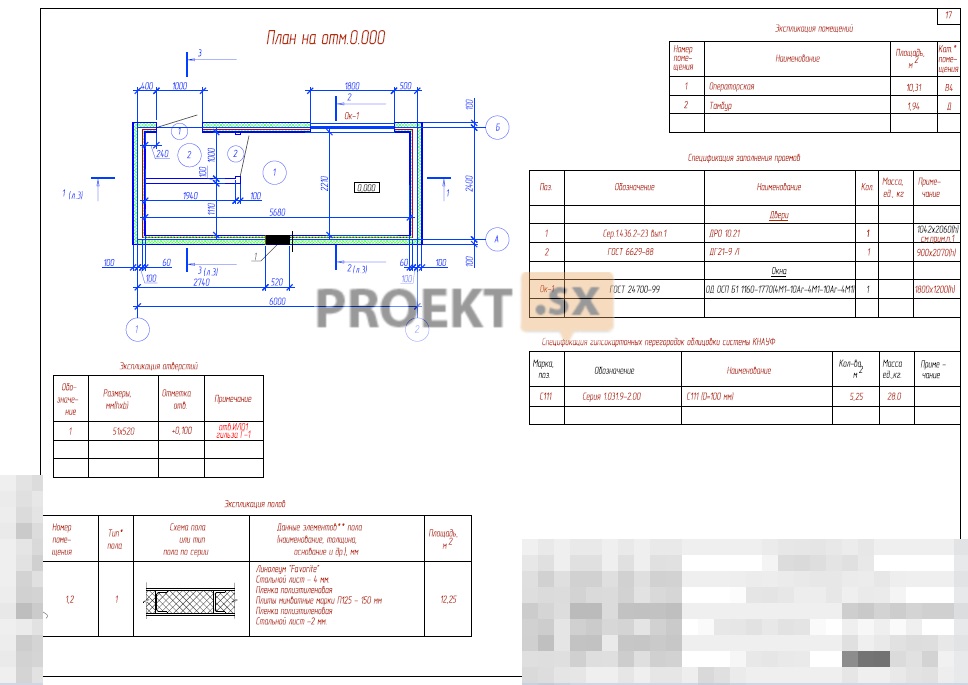

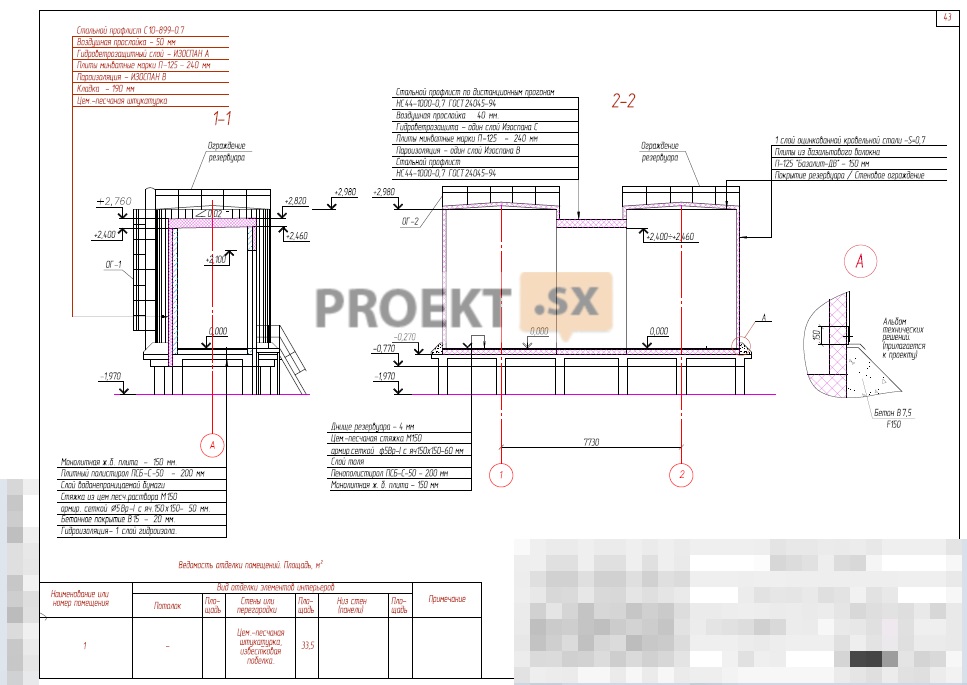

The construction part of the project developed architectural solutions for the following objects: Production building (foundation part, block container as part of the production building); Block container for storage of oils in a container; Block-container of storage inventory; Fire tanks 2x50 m3 with pumping station; Industrial building. The production building consists of a foundation part and ADES block-containers in the following composition: Block-container operator's room; Block-container of amenity premises; Block container repair shop and network pumping station; Block container ZRU-0,4 kV; Block container DGU-200 kW (2 units); Block container DGU-150 kW; Block container DGU-100 kW (2 units); Block container DGU-50 kW; Block container for fuel and oil preparation. The foundation part consists of two axes: axis 1-12 with a size of 25,3 m, axis A-B with a size of 17m. The design scheme of the frame is the load-bearing beams, roof beams and the system of connections. The connection of load-bearing beams with foundations is rigid. Spatial rigidity is ensured by placing ties along the bearing beams and roof beams. The foundations are piled from metal pipes d219x5,0 with a length of 6300 mm. Bearing structures - beams from rolled profiles. The service platform (cover) of the production building is made of a metal sheet along the beams of the lentil cover, 5 mm thick. The porches of the foundation of the production building are made of a rolled profile (channel), the steps are made of a metal sheet of lentil design. The fencing of the production building is made of a metal corner. All block containers are made on the basis of a standard 24-ton container of standard size 1CC GOST 18477-79 *, insulated with Basalite P-125 and sheathed with profiled sheet C10-1000-0,7. Block containers are installed on the foundation structure in two rows. Between the rows there is a corridor-type space for the movement of ADES personnel. Operator block container. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,640 m. The building houses an operator room with an entrance vestibule. Floors - linoleum on sheet steel and metal beams. Walls and ceiling - profiled sheet on a metal frame according to the P111 Knauf type. The internal partition is plasterboard on a metal frame, type C111 Knauf. Insulation - mineral wool boards P125 according to GOST 9573-96. The window is a wooden two-chamber double-glazed window according to GOST 24700-99. Doors - external - metal insulated according to the village. 1.436.2-23 issue 1; internal - wooden according to GOST 6629-88. Block-container of domestic premises. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,625 m. The building houses the premises: a dining room, a dressing room, a bathroom, a vestibule. Floors - sheet steel with lenticular corrugation on metal beams. Walls and ceiling - plasterboard on a metal frame, type P111 Knauf. The internal partition is plasterboard on a metal frame, type C111 Knauf. Insulation - mineral wool boards P125 according to GOST 9573-96. Windows - wooden two-chamber double-glazed windows according to GOST 24700-99. Doors - external - metal insulated according to the village. 1.436.2-23 issue 1. Block container ZRU-0,4 kV. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,575 m. The building houses the switchgear room. Floors - sheet steel with lenticular corrugation on metal beams. Walls and ceiling - profiled sheet on a metal frame according to the P111 Knauf type. Insulation - mineral wool boards P125 according to GOST 9573-96. The window is a wooden two-chamber double-glazed window according to GOST 24700-99. Doors - external - metal insulated according to the village. 1.436.2-23 issue 1; internal - wooden in accordance with GOST 6629-88. Block container repair shop and network pumping. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,585 m. The building houses the following premises: a heating point, a repair shop, an entrance vestibule. Floors - sheet steel with lenticular corrugation on metal beams. Walls and ceiling - profiled sheet on a metal frame according to the P111 Knauf type. The internal partition is plasterboard on a metal frame, type C111 Knauf. Insulation - mineral wool boards P125 according to GOST 9573-96. Windows - wooden two-chamber double-glazed windows according to GOST 24700-99. Doors - external - metal insulated according to the village. 1.436.2-23 issue 1. Block container DGU. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,585 m. The building houses the block-container DEU-200. Floors - sheet steel with lenticular corrugation on metal beams. Walls and ceiling - profiled sheet on a metal frame according to the P111 Knauf type. Insulation - mineral wool boards P125 according to GOST 9573-96. Exterior doors - individually made metal, insulated single-leaf and double-leaf doors with a hatch. Block-container for fuel-oil preparation. The building is rectangular in plan with dimensions in the axes of 6,0 × 2,4 m. The height to the top of the container is 2,585 m. The building houses a fuel and oil preparation room. Floors - sheet steel with lenticular corrugation on metal beams. Walls and ceiling - profiled sheet on a metal frame according to the P111 Knauf type. Insulation - mineral wool boards P125 according to GOST 9573-96. Windows - wooden two-chamber double-glazed windows according to GOST 24700-99. Doors - external - metal insulated according to the village. 1.436.2-23 issue 1. Block-container for storage of oils in containers (barrels). The oil storage building consists of two block-containers connected together. The block-container of the room for the warehouse of the foam concentrate in containers (barrels) has dimensions of 2,4 x 6,0 m, a height of 2,46 m to the top of the container. Basalite P-24 and sheathed with profiled sheet C1-18477-79. The container is installed on a reinforced concrete slab foundation. The dimensions of the building in the axes are 2,4x6,0 m. Block-container of storage inventory. The building for storage of fire equipment is a block-container. The block container has dimensions of 2,4 x 6,0 m, height to the top of the container is 2,46 m. It is made on the basis of a standard 24-ton container of standard size 1SS GOST 18477-79 *, insulated with Basalite P-125 and sheathed with profiled sheet C10 -1000-0,7. The container is installed on a reinforced concrete slab foundation. The dimensions of the building in the axes are 2,4x6,0 m. Fire tanks 2x50 cubic meters with a pumping station. Steel vertical cylindrical tanks with a capacity of 2 × 50 cubic meters. m. are designed to provide the needs of the power plant with a supply of water for extinguishing a fire. For maintenance, the tanks are equipped with ladders. A fence is provided on the roof of the tanks. Tanks - steel, manufactured according to the questionnaire 39-12 / 2-ILO3, insulated and sheathed on the outside with galvanized sheet steel. The pump room is built between the tanks. The pump room is heated, the temperature and humidity conditions are normal, natural lighting is provided.