Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Cemetery project

Technical and economic characteristics of the capital construction object

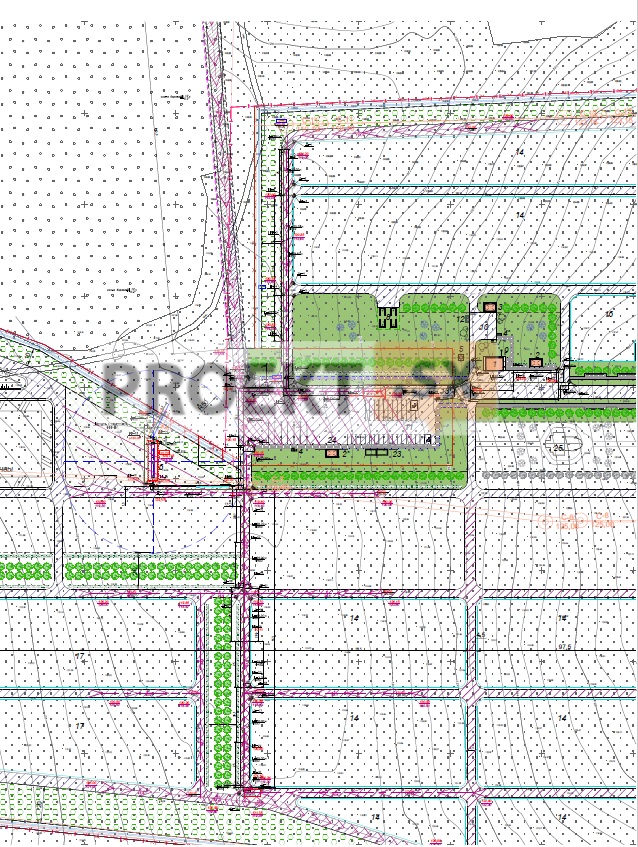

Land area: 39,0612 ha,

including I stage of construction: 11,24 ha,

II stage of construction: 5,3 ha,

III stage of construction: 9,77 ha,

IV stage of construction: 7,4 ha,

V stage of construction: 5,35 ha.

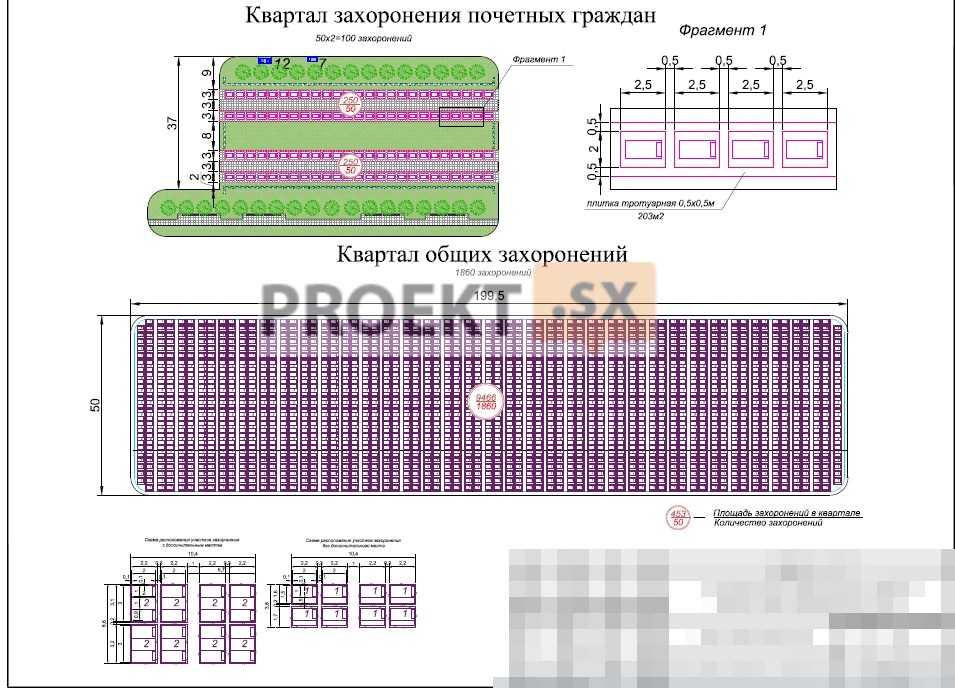

Burial area: 213451,1 m2,

Number of burials: 40000 places,

including I stage of construction: 4278 places,

II stage of construction: 9200 places,

III stage of construction: 6671 places,

IV stage of construction: 11501 places,

Estimated construction cost:

in the basic price level of 2001 (excluding VAT): 25188,03 thousand rubles,

in the price level. Q1 2016 (including VAT): - 187335,63 thousand rubles.

Type of functional purpose and characteristic features of the capital construction object: other, a cemetery for the provision of ritual services to the population with a traditional style of burial.

Architectural, constructive and space-planning solutions

The project documentation provides for the construction of an administrative building, a shady canopy for recreation (to stop public transport), a canopy for inventory, two underground fire tanks, tanks for technical water and irrigation, a complete transformer substation (KP 1), toilet cabins, and arrangement of platforms for containers, cemetery fencing, KTP fencing, waste sewer well, underground treatment facilities. All buildings and structures are designed for the following construction conditions: climatic area of construction - II century. Wind area -1 (normative wind pressure 23 kg/m2). The average temperature of the coldest five-day period is minus 28°C. Snow region - III (normative snow load 126 kg/m2). The administrative building is a one-story brick building with a combined roof, with an unorganized drain, without a basement, with dimensions between axes 1-2 and A-B 8,5 * 6,0 m, room height t 3,264 to 2,62 m in purity. The elevation of the top of the parapet is +3,970, the overhang is +2,870. The entrance to the administrative building through the insulated vestibule is designed in axis 2. For the relative mark of 0,000, the level of the finished floor is taken, which corresponds to the absolute mark of 125,250. The administrative building includes the following premises: an office with a place for eating with an area of 35,3 m, a utility room with an area of 4,4 m for storing documents, a room for a washbasin and cleaning equipment with an area of 5,0 m2, a vestibule with an area of 5,0 m2. The entrance porch is designed with a canopy and a ramp for people with limited mobility. External steel door insulated according to GOST 31173-2003. Doors internal wooden in accordance with GOST 6629-88 with painting with oil paint for two times. Window blocks made of PVC profiles according to GOST 30674-99 with single-glazed windows. Interior decoration of the premises provides for the use of the following finishing materials: water-based compositions for painting walls and ceilings; false ceilings of the Armstrong system in the administration room; plasterboard sheets in accordance with GOST 6266-97 in two layers for covering the ceilings of utility rooms and vestibules; ceramic tiles for wall cladding in the washbasin area in the utility room; ceramic tiles for covering the floor of the vestibule; linoleum for covering the floors of administrative and utility rooms. The composition of the base of the floors: concrete class B7,5 with a thickness of 80 mm; insulation made of extruded polystyrene foam PENOPLEX 35 TU 5767-006-56925804-2007 with a thickness of 50 mm; hydroglass layer; cement-sand screed Ml00 50 mm thick; base soil with rammed crushed stone fr. 40 60 mm thick. Exterior wall decoration - cladding with metal cold-formed panels with a polymer coating of the Siding type according to TU 5285-003-42481025-2006. Exterior finish of the plinth - painting with facade paint. Metal elements are painted with enamel PF-115 GOST 6465-76* barely a layer over the primer layer GF-021 GOST 25129-82*. The building is designed with a frameless structural scheme, with load-bearing transverse and longitudinal outer walls. Spatial rigidity is ensured by the joint work of the walls of the longitudinal and transverse directions. The foundation is made of prefabricated concrete blocks with a width of 400 mm according to GOST 13579-78 *, with a laying depth of 0,85-^1,15 m relative to the planning surface of the earth. At the intersections of the walls, the design documentation provides for the laying of meshes made of reinforcement 5 Vr-1 GOST 6727-80 * with a cell of 100x100 mm. Horizontal waterproofing is designed at a level of minus 0,020 from two layers of waterproofing. The foundation will be fine sand (IGE-2). External insulation of the basement and strip foundation to a height of 1,0 m is carried out with slabs of extruded polystyrene foam PENOPLEKS35 TU 5767-006-56925804-2007 with a thickness of 80 mm, followed by cladding with cement particle boards in accordance with GOST 26816-86. The outer walls are designed with a thickness of 380 mm from silicate bricks of the SUR M100 / F25 / 2,0 grade GOST 379-2015 on a cement-sand mortar M75 with external insulation and cladding of the Siding type TU 5285-003-42481025-2006 with cold-formed metal panels with a thickness of 0,55 .XNUMX mm with a paint and varnish polymer coating with fastening on a metal frame. The walls are insulated with ISOVENT mineral wool slabs TU 5262-005-53792483-2010, 100 mm thick (in two layers of 50 mm each with spaced joints) with fastening to the brickwork with an adhesive mortar and dowels with an external wind and moisture protective membrane Isospan A TU 5774-003-18603495- 2004. Between a heater and facing panels the air gap 50 mm thick is provided. Partitions 120 mm thick are made of silicate brick grade SUR M100 / F 15 / 2,0 GOST 379-2015 on cement-sand mortar M75. Partitions are reinforced with wire mesh 5 Vr-1 GOST 6727-80 * with a cell of 100x100 mm through four rows of masonry in height. Partitions are installed on foundation blocks (one row) 300 mm thick. Lintels - prefabricated reinforced concrete according to the series 1.038.1-1 issue. 4. The roof is shed (slope 10%), combined (like element-by-element sandwich panels), with an external unorganized drain and a parapet on three sides. Overhang overhang 0,6 m. Snow-retaining devices manufactured by the Metall Profile Group of Companies are installed along the roof overhang. The roofing includes: steel profiled load-bearing flooring grade H75-750-0,9 GOST 24045-2010 supported by external walls and a metal beam made of I-beam No. 30B1 GOST 26020-83. The metal beam is provided with support on the masonry of brick walls through metal distribution plates; vapor barrier film made of PVC layer; Z-profile purlins, provided in 1,0 m increments, galvanized grades nZhl50x3000, 1,2 mm thick, TU 1121-001-87370346-2015, GOST 52246-2004; mineral wool slabs Rockwool Roof Butts N TU 5762-005-45757203-99 150 mm thick (filling between Z-shaped runs); Z-profile purlins 50 m high in the transverse direction of the lower profiles, installed in 1,0 m increments, galvanized grade IIZh50x3000, 1,2 mm thick, TU 1121-001-87370346-2015, GOST 52246-2004; mineral wool boards Rockwool Roof Butts N TU 5762-005-45757203-99 50 mm thick (filling between Z-profiles brand IIZh50x3000); vapor-permeable membrane Tyvek GOST 2678-94; profiled steel flooring grade C44-1000-0,7 GOST24045-2010. The fastening of the profiled flooring to the guide profiles is carried out with self-tapping screws. Thermal separation strips are provided along the top of the Z-profiles. Along the perimeter of the building, an asphalt concrete pavement with a width of 1.0 m is carried out. The total area of the building is 49,7 m2. Construction volume of the building - 244,2 m3. The shadow canopy and the inventory canopy are semi-open free-standing structures with a shed roof with an unorganized drain, with dimensions between the axes 1-4 and A-B 6,0x4, Ohm, with a height to the bottom of the supporting structures from 2,3 to 3,0 m . The mark of the top of the coating (from paving slabs) inside the canopies is arranged 150 mm above the planning surface of the earth. The design scheme of the canopies is frame, with enclosing structures made of steel profiled sheet. The foundations of the frame pillars are monolithic concrete with a diameter of 500 mm, a height of 1,0 m, made of concrete of class B15, F150, W4, with a laying depth of 1,0 m relative to the planning surface of the earth. Fine sand (IGE-2) will serve as the basis of the foundations. Frame columns - steel pipes 102x3,0 mm GOST 10704-91. Column pitch 2,0 m. The columns are fixed to the foundations with four anchor bolts according to GOST 24379.1-2012 grade 1.1 Ml6x800 VstZps2 through the base plates. After installation, the columns are concreted with class B15 concrete up to the level of the top of the site (to a height of 200 mm). Wall purlins - channel No. 5 GOST 8240-97, GOST 27772-88 *. Cover beams - channel No. 16 GOST 8240-97, GOST 27772-88 *, span 4.0 m. Roof purlins - channel No. 10 GOST 8240-97, GOST 27772-88 * step 2,0 m. Wall fencing - steel profiled flooring grade C21-1000-0,7 GOST 24045-2010. Roofing - profiled steel flooring grade H60-845-0,7 GOST 24045-2010. Inside the shady canopy, a wooden bench for rest was designed to be mounted on metal brackets to the frame columns. Metal elements are painted with enamel PF-115 GOST 6465-76* in two layers over the primer layer GF-021 GOST 25129-82*. Wooden elements are covered with oil paint. The project documentation provides for the installation of two fire tanks, which are horizontal tanks buried in the ground "ARMOPLAST" LLC "Viteko" made of reinforced fiberglass TU 4859-001-98116734-2009 with a volume of 55 m3, a diameter of 2,5 m, a length of 11,3 m. The depth of the bottom of the tanks is 3,5 m relative to the embankment surface of the site. The embankment of the reservoir site is carried out with slag, to a height of 0,7 m relative to the planning surface of the earth, followed by covering with a soil and vegetation layer of soil 0,3 m thick. The tank for technical water and irrigation is a ground tank with overall dimensions of 2,5x1,25x1,25 (h) m, made of steel sheets 4,0 mm thick GOST 19903-74*. The tank is installed on a support frame made of corners 125x125x9 and 75x75x6 mm GOST 8509-93, GOST 27772-88* (racks and struts), dimensions in terms of 2,5x1,25 m, height 0,5 m relative to the ground. A monolithic reinforced concrete slab made of concrete of class B15, F150, W4, 150 mm thick, dimensions 2,7x1,45 m, with reinforcement with two meshes of reinforcement 10-А-Ш GOST 5781-82 * with a cell 150x150 mm. The depth of the slab is 0,15 m relative to the ground. The foundation slab is made of concrete class B7,5 with a thickness of 50 mm. The base frame is welded to the embedded parts of the foundation slab. Metal elements are painted with TDR-50 enamel TU 2312-018-98310821-2009 over a layer of primer EP-011 TU 2312-023-76044141-10. The bottom of the supports of the support frame is additionally protected against corrosion with cold bitumen-rubber mastic MBR-X TU 5775-001-00287912-2005. At the base of the foundation slab, it is planned to cut off the soil and vegetation layer, and to install a compacted cushion of sand of medium size with a thickness of 0,3 m. The base of the sand cushion will be EGE-2, fine sand, medium density or EGE-3, hard-plastic loam. The PTS is installed on two prefabricated reinforced concrete racks of the brand SON 44-29 according to the series 3.407.1-157. Installation of racks is provided for in pre-drilled wells with a diameter of 0,45 m, a depth of 3,07 m, for crushed stone preparation 300 mm thick, backfilled with sand and gravel mixture with layer-by-layer compaction. Installation of reinforced concrete poles for the external power supply line VLZ-YukV grade SV 110-5 (concrete grade F200, W4) according to TU 5863-007-00113557-94, adopted according to series 27.0002, with variable pitch, is provided for in pre-drilled wells with a diameter of 0,35 m , with a depth of 2,5 to 2,65 m, with careful compaction of the backfill soil. Installation of racks SV 110-5 of anchor and corner supports is carried out on support-anchor plates of the P-Zi brand according to the code 27.0002. The intersection of the projected VLZ-10 kV with the existing V L-0,4 kV is provided for on transitional reinforced concrete supports adopted according to series 21.0050 of grade PPoB10-1, grade PA (K) tB10-14 with reinforced concrete racks of grade SI-2 TU 5863-009- 00113557-95 and SV110-2 TU 5863-009-00113557-95. Installation of supports is provided in pre-drilled wells with a diameter of 0,45 m, a depth of 2,5, 2,0, 2,75 m, with careful compaction of the backfill soil. The base of the racks will be hard-plastic loam (IGE-3).